Behind the walls

Written by

25 February 2021

•

3 min read

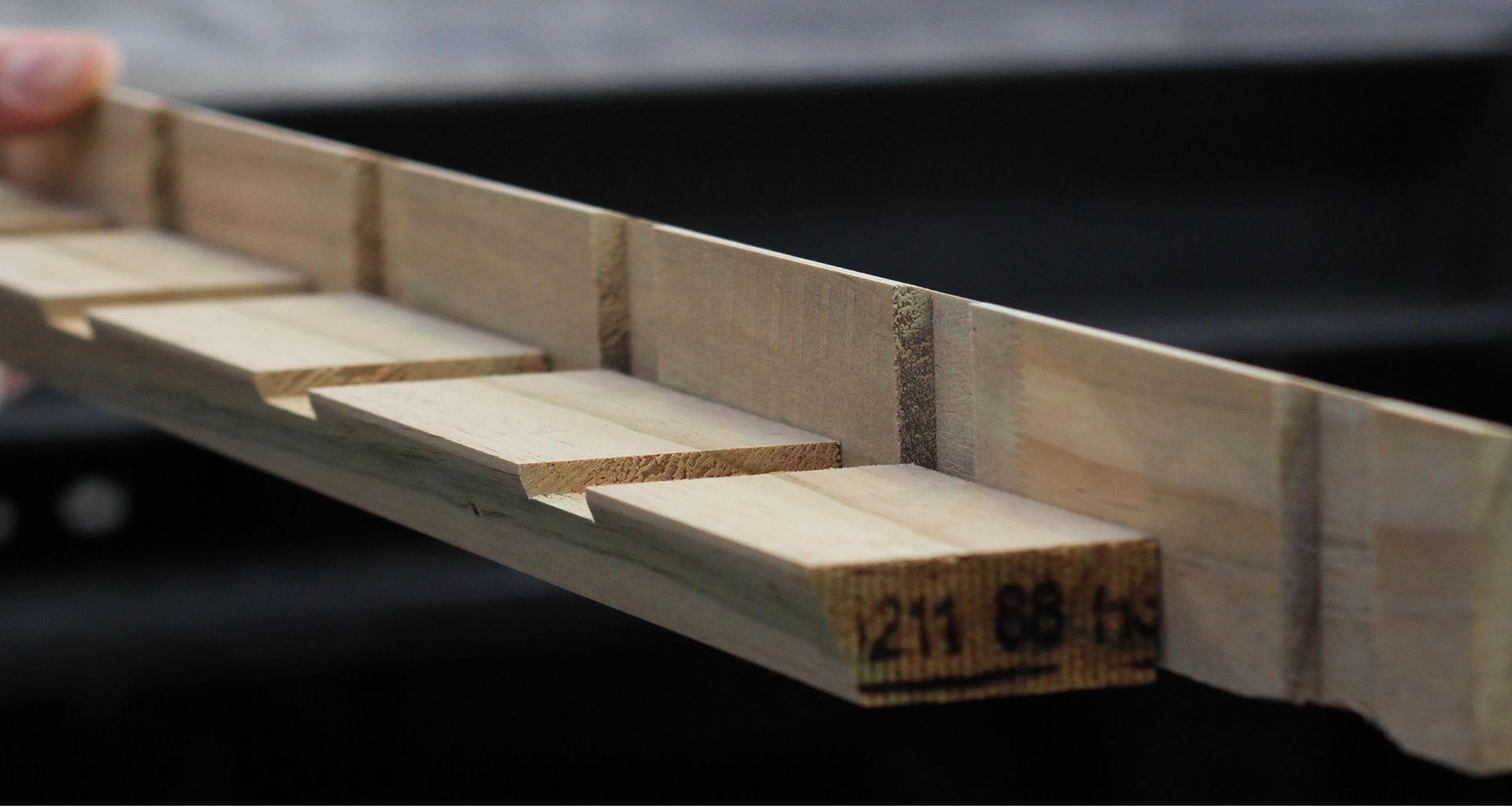

When what you manufacture ultimately disappears behind the cladding, it’s easy for home or building owners to overlook just how important a contribution your product makes. Castellated timber battens are one such product, yet they’re crucial for both structural reinforcing and weathertightness.

“Once they’re in you never see them again—they’re not a glamour product, but they are essential to maintain the structure and to prevent water damage,” says Marten Hielkema from Ezyscribe, which manufactures a range of castellated timber cavity battens.

Vented cavities are required by the Building Code, so for any building with panelled cladding such as plywood or cement board cladding, and for any building with vertical cladding, such as vertical cedar, vertical fibre cement, vertical corrugated iron, a castellated cavity is the best solution.

This is because the castellations routed into the timber cavity battens allow water and air to escape the cavity.

Protecting your home from the inside

“If you put a standard batten horizontally behind a vertical cladding, it essentially becomes a dam, creating moisture build-up and entrapment. The castellations create cavities which allow water to drain away and air movement to occur.”

The benefits of using timber battens are numerous, says Marten, particularly given that builders are trained in working with wood and the tools they carry are generally designed for modifying timber.

“Timber is easy to modify and because it’s a solid material it won’t shatter, collapse or be crushed if compressed too much.”

Ezyscribe’s castellated cavity battens come in a range of different treatments, which all meet Building Code requirements. The H3.1 battens have a standard LOSP (light organic solvent preservative) chemical treatment (applied by vacuum pressure impregnation) which protects the integrity of the wood, while H3.2 are CCA (chromated copper arsenate) treated.

Sourced from sustainable New Zealand forests

An alternative H3.2 batten is treated with MCA (micronized copper azole) and is preferred by clients looking for an environmentally friendlier alternative to CCA.

One of the other advantages of the H3.2 MCA treatment is that it is less corrosive than the other H3.2 treatments and therefore has less impact on metal fastenings such as screws and nails if it comes into contact with water.

Regardless of whether your construction project has a green requirement or not, current supply chain issues and huge demand for materials in the building industry are putting pressure on construction product suppliers across the board.

However, because Ezyscribe’s timber is locally sourced and kiln dried (meaning you don’t have to sit around waiting for it to dry)—plus, they have a number of local manufacturing plants supplying them—they’re still able to deliver product within days of an order coming in.

“Thanks to our locally based facilities and increased manufacturing capacity, we’re able to turn around product much faster than suppliers reliant on internationally sourced variants,” says Marten.

Learn more about how you can incorporate New Zealand-made cavity battens into your next project.