How one New Zealand timber merchant is using technology to improve buildability

Written by

02 August 2018

•

5 min read

When New Zealand amended the Building Code to include cladding fixed on a cavity, the industry found itself with hundreds of projects that couldn’t get compliance. That’s because although the Building Code introduced the use of cavities, there was still no provision for cavities using horizontal battens, which are required for vertical shiplap weatherboard applications.

“This was when vertical shiplap was just becoming very popular. A simple solution was to turn the vertical boards horizontally, which was the birth of modern rusticated weatherboards.

“Rusticated weatherboards were traditionally manufactured with a 40 mm scalloped rebate, as seen on villas and rural buildings, which isn’t very architectural or creatively focused.

So we used our vertical boards and turned them horizontally. We took those same 9 mm deep, 6 mm wide negative rebated boards, put a slope on the top to form a drip edge and a slope on the bottom for drainage, and that was the advent of modern rusticated weatherboards.”

Since then, the Cedar industry has led the charge in terms of refining and modifying traditional timber profiles. Rosenfeld Kidson continues this innovation with all other aspects of their Cedar weatherboard systems. According to Ray, Rosenfeld Kidson’s commitment to quality and inventiveness is their key differentiator.

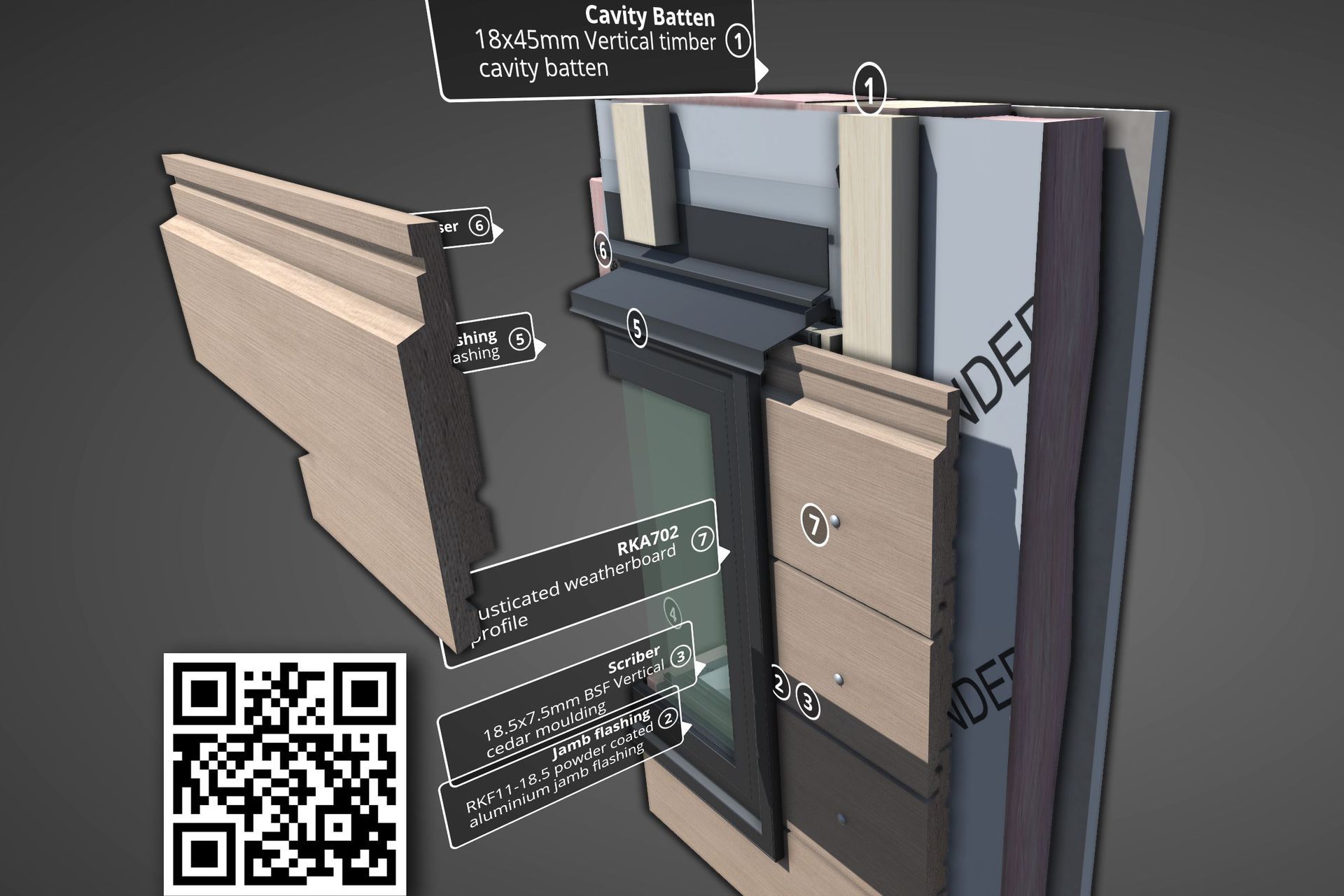

“With our Cedarscreen Rusticated weatherboards for example, we recognized that the window is by far the most critical element of a facade in relation to weather-tightness. We developed the system to achieve optimal weather-tightness with the use of our J mould and conceal- fixed scriber detail, which helps achieve a flush, yet weathertight solution. To further help with the buildability and visual aspect, we have created a new mitred external corner detail that not only simplifies the build, but also helps to seamlessly link the timber façade from face to face.

“We’ve consistently led the way with innovation and are very creative with detail. We’re all about simplifying the build and high-end architects love us because we give great advice on how to use the product.”

And they’re doing just that with an incredible new solution called Working Spec. The Working Spec app links animated 3D-models to QR codes on product details, brochures and architectural plans. Rather than interpreting confusing 2D drawings and brochures, a builder or specifier can scan the code to interact with a full 3D model of the product or solution on their tablet or mobile device.

Working Spec bridges the gap between manufacturer and end-user and overcomes the key issues with traditional instructions and even current 3D-modeling systems. While solutions do exist, they’re often software dependent, making 3D modeling out-of-reach for most builders and end-users.

Rosenfeld Kidson has been using the Working Spec app exclusively to showcase their systems for the last twelve months and, according to Ray, the difference has been monumental.

“Working Spec greatly increases the buildability of the detail. We have excellent literature, but this is the next level - a tool that shows exactly how certain details must be done. We’ve worked closely with our builders and taken on a lot of feedback to refine the experience and ensure they have the tools needed to achieve the right outcome.”

When you download the Working Spec app and scan one of Rosenfeld Kidson’s unique QR codes, you truly see the build come to life. Not only that, but you can hover over the animation, change your view, zoom in and read an exact description of certain components in the system.

“Working Spec breaks down barriers in understanding and simplifies the building process. Essentially, it’s a buildability tool that can be used to understand how products are designed and then executed on site.

In the past, we were working with 2D details and trying to explain technical details without enough context. To aid understanding, we’d usually send someone to the site and we found that this increased the time spent on each project significantly. Now, however, Working Spec does this for us and it does so in a way that’s consistent and can be shared easily.”

As Ray puts it, “This isn’t necessarily a new technology, but it’s being used differently. What’s great about the interactive instructions is that they’re dynamic. This isn’t a static 3D render; it’s an animated tool that allows you to understand the sequence of the build, as each element comes together.”

The most obvious advantage of Working Spec is that it increases the builder’s understanding and skill level, but Ray notes how the app has significantly improved Rosenfeld Kidson’s product reps’ knowledge as well.

“I work with some of the best technical sales reps out there, all of which are able to competently articulate information around the facade in an accurate manner.”

This, of course, stems from the fact that they just get it - as does anyone else with access to the 3D animations. Architects, specifiers and owners can all glean a full understanding of the build using the app. Plus, this information is all in one place, compared to the current system where product details are disjointed - scattered among various websites, brochures and other documents.

“Eventually,” says Ray, “they’ll sell this concept to other manufacturers and I’m sure everyone will jump on the opportunity.”

Currently, however, Rosenfeld Kidson is alone in their access to this impressive tool, which is available for all rusticated and vertical weatherboard systems, as well as their INTERSET recessed window flashing system (now available for rusticated as well).

“We’ve been responsible for several key systems over the last 20 years. Innovation is great,” says Ray, "but often innovation creates challenges around buildability. This development, on the other hand, removes them. Working Spec creates a synergy between the creative mind and technical aspects of the build.”

Want to learn more about the New Zealand specialist timber company that’s always on the cutting edge? Check out Rosenfeld Kidson on ArchiPro today.