Valuing sustainability

Written by

23 February 2021

•

5 min read

On Thursday, 7 November 2019, the New Zealand Government passed into law the Climate Change Response (Zero Carbon) Amendment Bill, also known as the Zero Carbon Bill, which seeks to provide a framework to implement climate change policies in line with the government’s commitments made under the Paris Agreement (2015).

To ensure the country reaches its goal in combating climate change, late last year the government launched a major new initiative that will require the public sector to achieve carbon neutrality by 2025. A number of New Zealand businesses have already reached carbon neutral certification and many more are following suit.

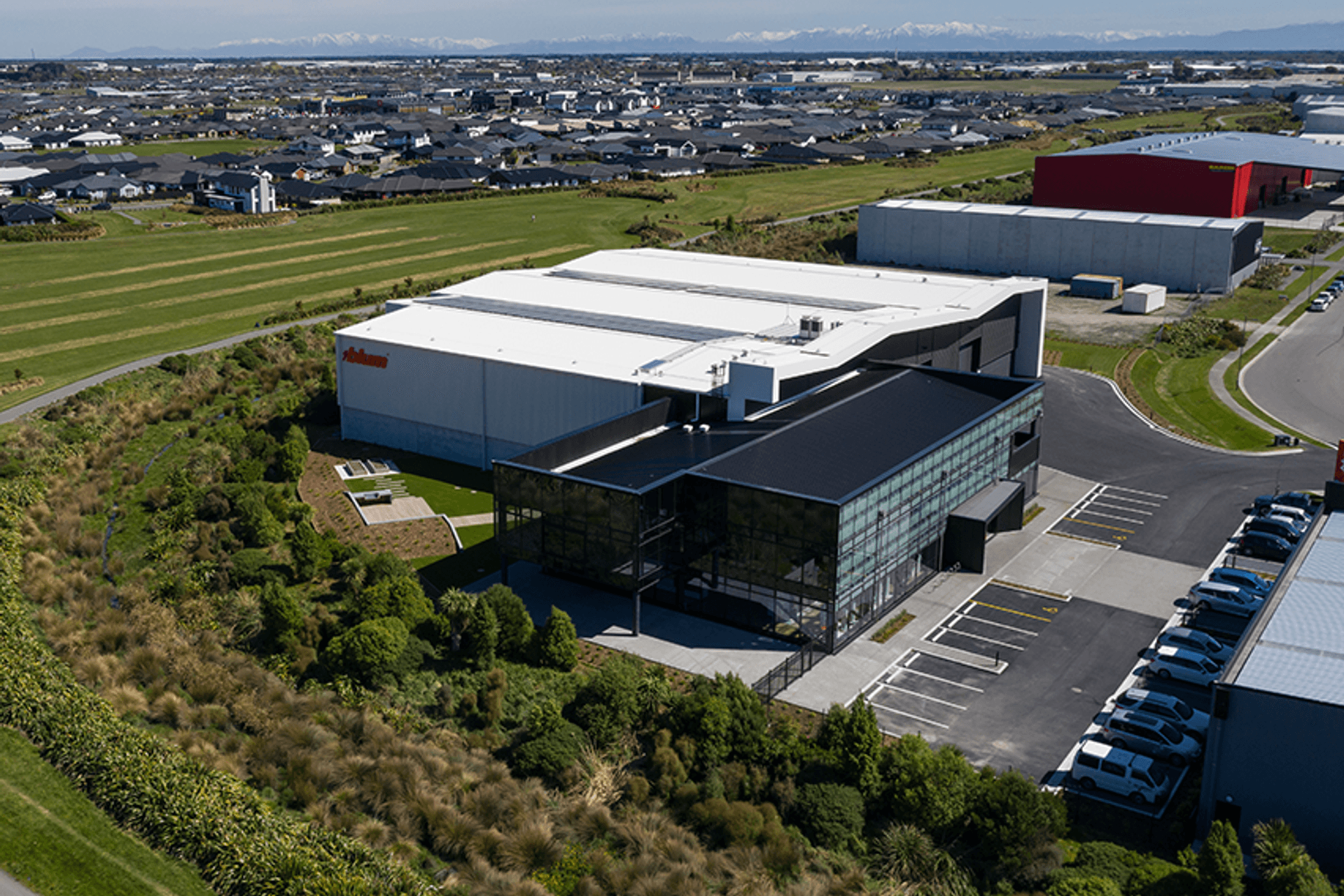

Global hardware manufacturer, Blum, has proven its commitment to achieving this target with its new showroom and warehouse in Christchurch. Michael Hawkins, the Managing Director of Blum New Zealand, wanted to make the Christchurch showroom as ‘green’ as possible and so was really invested in incorporating a number of sustainable technologies into the building, says Steve Langley, Mechanical/Hydraulic Engineer for Cosgroves.

“We handled the mechanical and hydraulic design for the showroom, working in conjunction with architects Warren and Mahoney and, of course, Blum."

A green design that’s fit for purpose

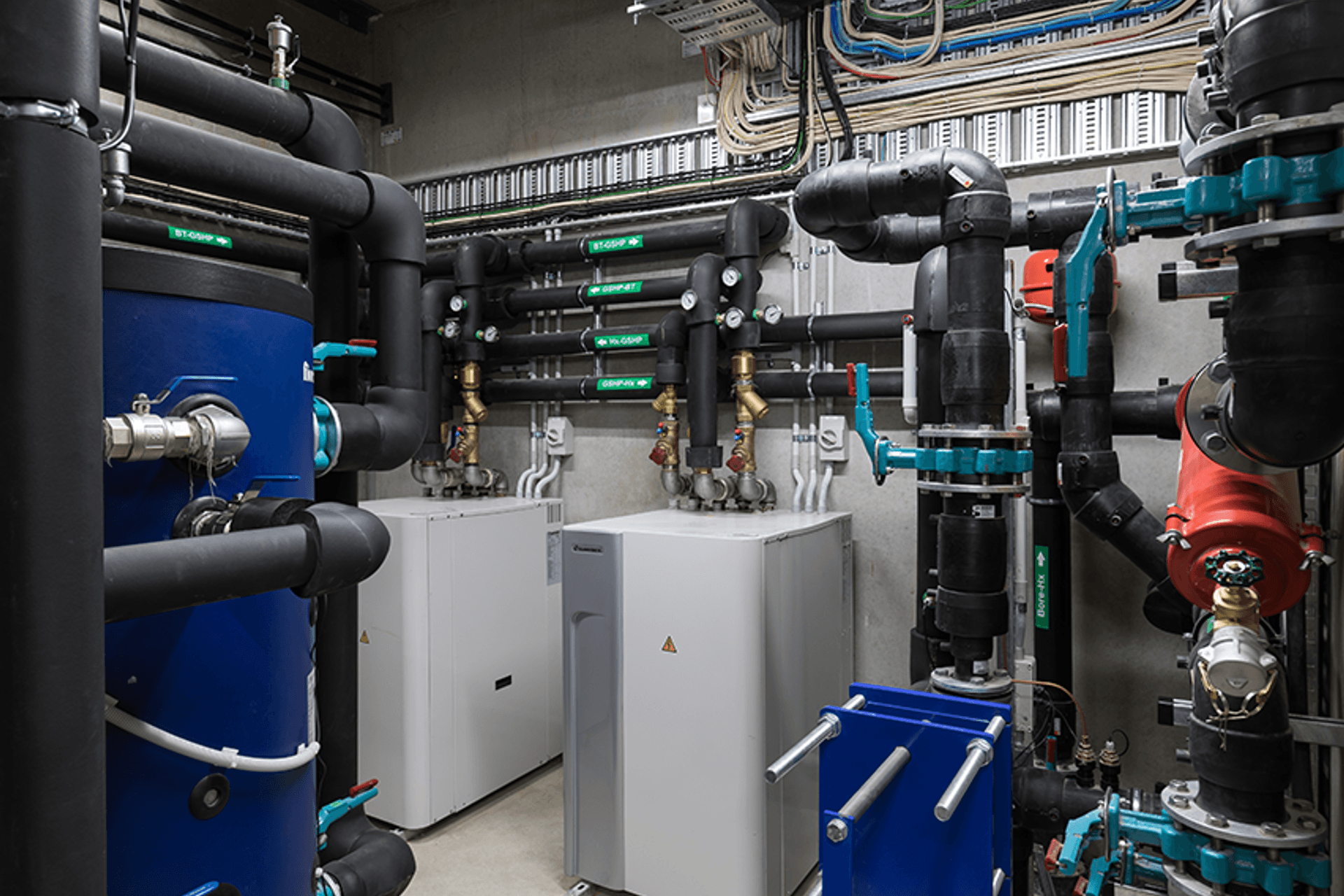

“The showroom component of the building is essentially a big, glass box. It looks great but throws up problems in terms of solar gain and heat loss. Working with the architecture, we installed a trench heating system around the perimeter that allows us to run both heating and cooling through the space without having to introduce any visible ducting or mechanical equipment. The trench heaters work by countering the downdraughts from the glazing,” says Steve.

“The trench heating is fed via an open loop ground-source heat pump system from a vertical bore, that powers three heat pumps, which also provide underfloor heating to the warehouse packing area and bathrooms, as well as the ground floor offices. The system that we have designed, as well as being highly energy efficient, will last for the life of the building; a good 50 years. The lifespan of a product is often not considered when we think about sustainability and environmental impact. The environmental cost of the replacement of a conventional system; three or four times over this period of time, is significant. Ground-source systems are ideal for a long-term solution as they are generally more robust than typical air-source systems, so there is less ongoing maintenance and repair, and the energy efficiency COP remains constant throughout the year.

“The Cosgroves team also utilised a natural ventilation strategy through the showroom, installing a number of motorised actuators controlled by an automated weather station and incorporating CO2 sensors and temperature sensors. When the system senses rain or high winds it automatically closes the windows and a back-up ventilation system kicks in.”

Steve says the system was designed to be fully automated but is also able to be manually controlled via touchscreens. “The controls for the natural ventilation is a fairly clever system and the savings in reduced long-term energy usage covers the up-front cost.”

Going green from the floor to the roof

A photovoltaic array has also been installed on the roof to offset the building’s energy consumption, a logical choice for businesses such as Blum, who mainly operate during daylight hours. Similarly, diesel-fuelled and LPG-fuelled equipment such as forklifts, have been replaced with electric models and are typically recharged using 100 per cent renewable energy generated from their own energy source—which means the company is further reducing its dependence on fossil fuels.

EV chargers have been installed in the carpark so staff and customers are also able to capitalise on the PV installation, while rainwater harvesting provides non-potable water for toilet flushing and irrigation, to reduce water consumption and discharge.

“We don’t often get the opportunity to design systems such as this but Blum was wholly committed to the long term benefits offered by the design and willing to make the upfront investment in order to reap those benefits down the road,” says Steve.

“None of what we’ve specified is particularly new, from a technology standpoint. The most difficult aspect is always finding a client as willing and as committed as Blum was, to pull it all together.

“I've been in the industry for over 13 years now, both here and in the UK and there is still very much a perception of New Zealand ‘being behind’ the rest of the world but in reality, the marketplace here is really beginning to latch on to the wider sustainability know how, especially thanks to greater access to some of the truly innovative tech coming out of Asia. The gap between Europe and the rest of the world is no longer as pronounced as it was a decade ago.”

Committed to making a difference

Steve says that while the design incorporates Green Star features, Blum chose not to go through the accreditation process.

“A lot of businesses can be put off from going down the certification route as it can be very time consuming and costly. It’s not a requirement here yet, although I expect we may follow a similar route to what Australia does sometime in the future.

“Really, from the client’s perspective, it’s a fairly straightforward process. It does require some additional thought and time through the design process, as well as some additional fees to be factored in, but aside from that, businesses just need to be committed to making a difference. We have the team, knowledge and skills at Cosgroves to guide clients through the process.”

Learn more about Blum's new Christchurch facility.