Vertical horizons

Written by

16 March 2017

•

4 min read

Vertical shiplap cedar cladding is a bold statement. Its verticality alone adds a dramatic aspect to any facade, while the natural variants of Cedar have long made this a popular choice for cladding. Limitations in the Building Code around its use have led to a rapid development of this cladding type as an Alternative Solution.

Within the Building Code there is no provision for use of a horizontal cavity batten because of the risk of moisture getting trapped behind the cladding and having no point of egress. Over the past 15 years, this restriction has led to the development and testing of cavity systems to overcome this limitation and meet the ever increasing demand for this cladding type.

“This means that if you want to use a horizontal batten, you must have it tested and approved as an Alternative Solution,” Rosenfeld Kidson’s Ray Hutton says.

“Restrictions in the use of vertical cladding have all changed with development of ventilated cavity batten systems. Our CodeMark certified structural cavity batten system is a further progression, improving performance and extensively broadening the range of applications where it can be used,” Hutton says.

Independent CodeMark certification of the system as an Alternative Solution has greatly increased its scope of use. Design and testing was to Amendment 5 of E2/AS1, including the Extra High wind zone and specific wind pressure was tested up to a maximum ultimate limit state (ULS) of 2.5 kPa. Where vertical cladding could previously only be used as a direct fixed option in areas with a risk matrix score of 0-6, this system allows vertical cladding to be used in areas with a risk score of 0-20, meaning it can be used almost anywhere in the country and local authorities are assured to accept it.

Standard horizontal cavity battens are 20mm thick, which means that the weatherboards are face-nailed through the weatherboard, through the batten, through the building underlay and into the framing behind. Long nails are needed – either 75mm or 85mm and Silicon Bronze or Stainless Steel are used, which are relatively soft materials and can leave room for error in fixing, being easy to skew and miss the framing. This can create a pathway for moisture to travel from the cladding face to the underlay. 20mm battens also require additional framing for support, practically doubling the number of nogs/dwangs required.

“With our 45mm system, the batten is structural and therefore does not require any additional framing for support. We are able to replace this additional wall mass of timber framing with insulation, adding to the walls R-value. It’s also much more durable with a 50-year minimum lifespan compared to a 15-year durability requirement for 20mm battens,” Hutton says.

Designed to span the studs, the 45mm battens are fixed to the framing and then the weatherboards are fixed with shorter 60mm nails directly to the battens alone, with no need to puncture the building underlay with face fixings. “This maintains the integrity of the underlay so the cavity can remain pressure equalised, which is the best way to prevent moisture being drawn into the cavity.”

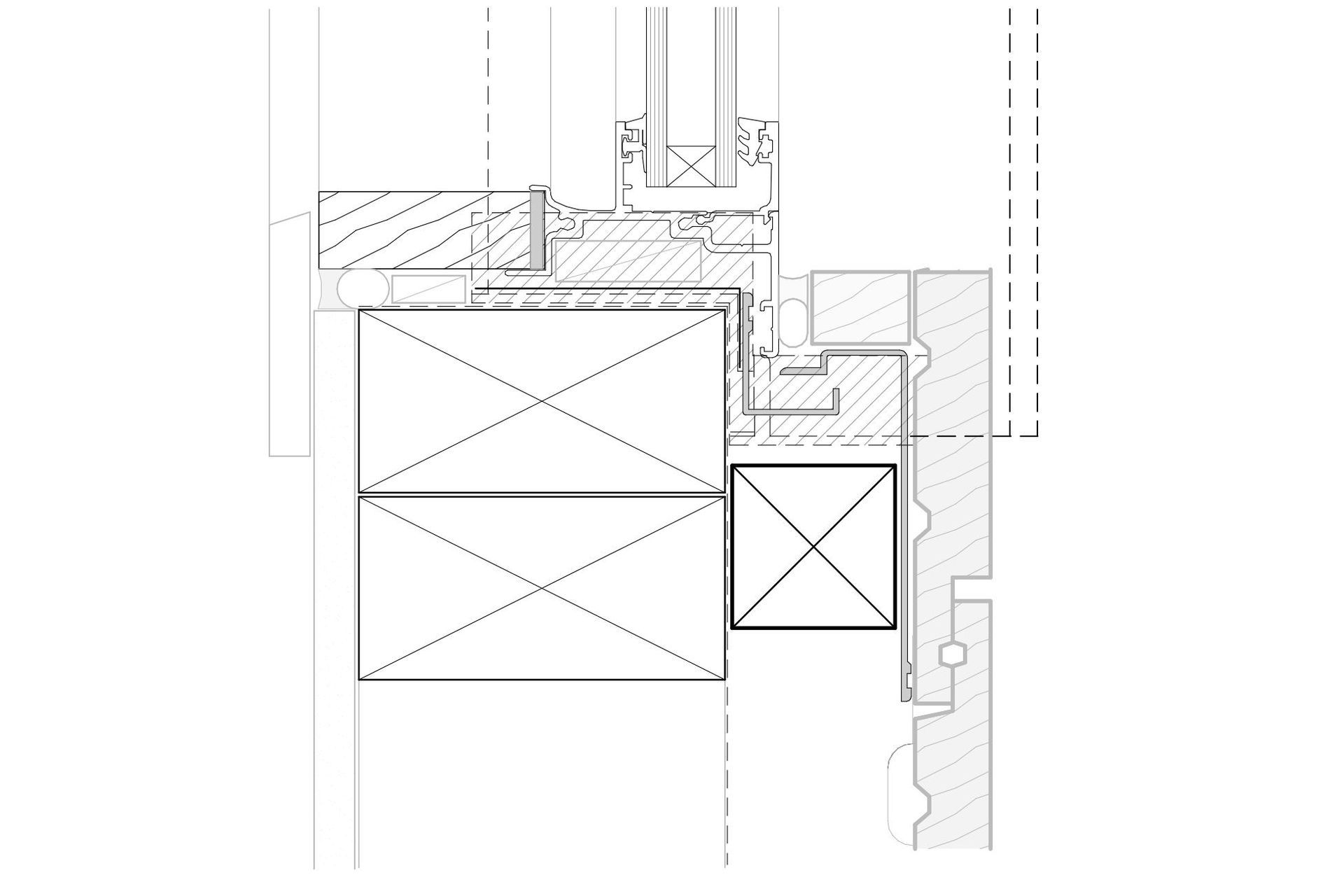

The latest evolution of this system is that Rosenfeld Kidson now offers INTERSET® – a Recessed Window Flashing System for vertical cladding in Cedar or Larch. The window joinery is pulled back to the frame and flashing line and the opening is clad around and into, to create a minimum 65mm recess.

This clever solution achieves a clean and contemporary look but also improves thermal and weather-tightness performance.

Rosenfeld Kidson is approaching 85 years in business and Director Mark Liggins says, “With Ray’s focus on innovation supported by the company’s wealth of experience, we really have a great collaboration to bring exciting new products and practical solutions to the architectural market.”

“From the cool clean lines of narrow profiled boards with crisply profiled joints, through to random depth and width weatherboards that evoke images of the richly textured environment many of our buildings find themselves in, vertical weatherboards can be manipulated to exploit the whole range of possibilities that timber provides.”

Visit Rosenfeld Kidson on ArchiPro here to find out how you can incorporate vertical shiplap cedar cladding in your next project.

Credits: Title Image – Briar Bank House by Rafe Maclean Architects, photography by Simon Devitt Photographer