Changing the way the world builds

Written by

28 July 2020

•

4 min read

We Kiwis are celebrated for our can-do, ‘number 8 wire’ mentality, however, we can also stubbornly cling to the past, especially at an industry-wide level where change can be slow-paced.

“When I first started importing rigid insulation board 30 years ago, pretty much the only insulation available in New Zealand was glass wool insulation; that was the industry standard and had been for years, so while rigid options were proving more popular and better suited to a wider range of applications overseas, glass wool insulation remained the market leader here,” says Composite Insulation Director Alan Freeman.

“Needless to say, a lot of our time in the beginning was spent educating the industry to the benefits of extruded polystyrene and foam insulation boards.”

Benefits, Alan says, which include being able to be used below grade, in the case of XPS extruded polystyrene.

Good things come in threes...

“Goldfoam XPS extruded polystyrene insulation is closed-cell, which means it is waterproof, making it ideal for below-grade, slab edge and underfloor applications.

“Besides multiple underfloor applications, Goldfoam XPS insulation is extremely versatile and can also be used as a high-performing insulation product in walls. XPS can be used with timber and steel stud application and over building paper with brick and stone veneer, preventing thermal shorts through framing. It can also be placed over battens for EIS systems where high compressive strength is a requirement. In blockwork or concrete walls, XPS can be placed between the battens where condensation isn’t absorbed by the insulation.

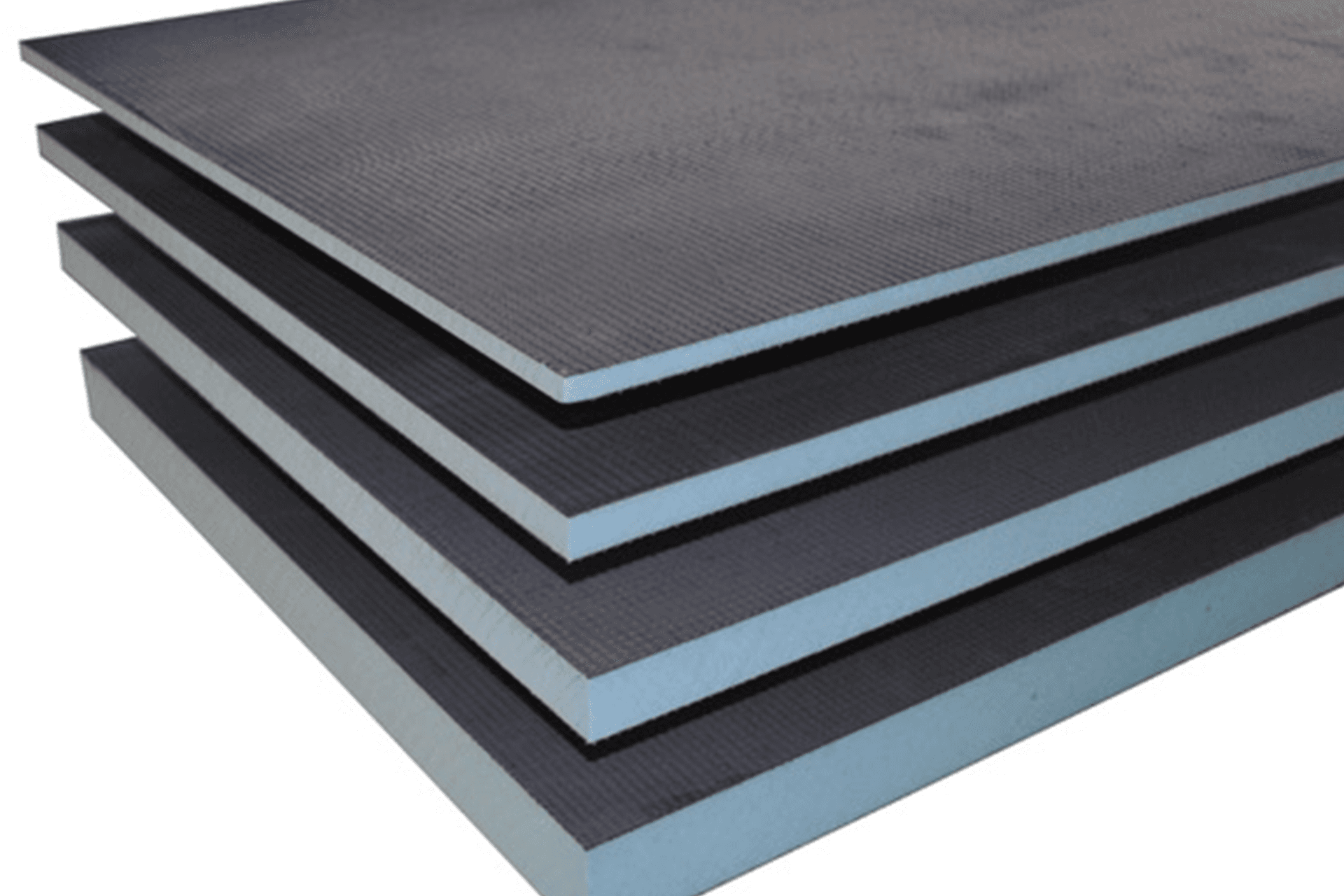

“Similarly, we offer high-quality tile backer boards for use in bathrooms and other wet areas. Like Goldfoam XPS, these products are waterproof and rot-resistant, as well as being lightweight.”

With extruded polystyrene gaining greater acceptance locally, Alan started offering the market a PIR (polyisocyanurate) insulation board product manufactured by a leader in the market, EG Board.

“The major benefit of PIR insulation board is that it offers the highest R-value of any material per thickness. For example, at 100mm thickness, PIR board has an R-value of 5.2, which is four times the Building Code requirement for floor insulation and almost twice that for roof insulation in Zone 1 and 2 areas of New Zealand. It is more than 1.5 times the roof insulation requirements in Zone 3 areas of New Zealand,” says Alan.

“For this reason, PIR insulation is ideally suited to homes that have features such as skillion ceilings or similar structures where there is little to no roof cavity. It is also a good option for loft or attic conversions as it has little impact on reducing the overall ceiling height.”

Thermomass: insulating from the outside

The final product line offered by Composite Insulation is Thermomass, an insulated concrete sandwich wall system in which extruded polystyrene insulation is sandwiched between two layers of concrete during casting.

“Thermomass is the proven system when it comes to New Zealand conditions. The fact that the building is insulated from the outside means the thermal mass capabilities of the inner concrete layer can be used to passively regulate the internal temperature, helping reduce energy costs—in some cases up to 50 per cent,” says Alan.

“Similarly, issues of condensation are a thing of the past as the full-face insulation layer and lack of thermal shorts between concrete layers mean the dew-point temperature is never reached. When paired with thermally-broken glazing this process is assisted even further.”

The benefits of consulting an industry expert

“Following changes to the Building Code, which began in 2007, calling for greater insulation requirements in all new builds, as well as, more recently, making ceiling and underfloor insulation compulsory in all rental properties, we’re going to see continued increased pressure on government to legislate ongoing improvements in and around insulation and energy consumption,” says Alan.

“That’s where Composite Insulation can step in to assist New Zealand architects and designers to create buildings with increased energy efficiency, durability and performance. And, for contractors and buildings, because we specialise in only three product lines—XPS extruded polystyrene and tile backer board, PIR insulation board and Thermomass ICP—we are able to carry greater levels of stock in our Christchurch and Napier warehouses. Higher stock levels mean faster lead time on orders, so we can assure customers of prompt delivery throughout New Zealand.”

Learn more about extruded polystyrene and rigid board insulation.