Bigger is better

Written by

18 May 2021

•

4 min read

As the population of Tamaki Makaurau/Auckland continues to grow and the urban area expand, former rural areas are quickly becoming satellite towns for people working in the CBD. Silverdale is one such area experiencing the effects of this expansion with its population growing by 35 per cent in the six years to 2020.

Located 30kms north of Auckland, Silverdale attracted a number of light industrial and commercial businesses—such as Herman Pacific—that were looking for space for stock and to expand. Now these businesses are feeling the squeeze as residential developments become the norm.

“It’s been 46 years since we began trading from what was, initially, a fairly modest site,” says Steve Carter, Sales and Marketing Manager. “We’ve expanded greatly in that time but further expansion was really out of the question and it was time to look for a site that allowed us to consolidate our facilities and to increase our capacity and output.

“Given the company’s history, we weren’t just looking to the next five years but rather 30–50 years into the future and the continued expansion of the business over that time. For that reason, we were really keen to get out into a region where we would not only have the opportunity to evolve and strengthen the business but to also help develop that community.

“So, when the opportunity arose to purchase a 40h site at Marsden Point, we didn’t hesitate.”

Hermpac: innovation remains the focus

Steve says the move to the custom-built 15,000sqm manufacturing facility has meant the company has been able to amalgamate staff and machinery from three or four sites in Silverdale into one building, bringing with it a number of benefits.

“Firstly, from a company point of view, this is a much more efficient operation with all of production under one roof. We’ve expanded and upgraded our facilities to the point where we’re 50 per cent bigger and have even more machinery coming in, which will allow us to double our capacity and output.

“Secondly, one benefit to our customers is the larger range of sustainable products, including new, FSC-certified species we’ve added to our offering, giving the market more choice. Thirdly, and most importantly, we’ve been able to create a great work environment for our team and staff, with many also making the move from Auckland and buying homes in the area.”

It has been a four-year journey from purchase through to the new site being up and running, says Steve, with the team working out of the new facility for around nine months now following the staged closure of the Silverdale site over the past year.

“We’re still working on building the operation with plans for further expansion over the next 12–24 months to reach full capacity. This will include hiring a further 20–30 staff to augment the current number of 70–80 staff.”

Hermpac: premium timbers that don’t cost the earth

Another benefit of the move has been the proximity to Northport, which Steve says the company already brings some product into and is hoping to expand this as an option in the near future as the two organisations have a good working relationship.

“Another big focus for Hermpac is sustainability and our considered master plan, which included the development of this new facility, has enabled us to utilise our supply better and to offer more sustainable timber solutions.

“Hermpac is already the distributor of Accoya® timber, a modified New Zealand radiata pine timber product that is extremely durable, sustainable and stable and is also a big hit with homeowners as it holds a painted finish incredibly well, particularly when painted black.

“We’re also always looking at ways to lessen waste and we’ve managed to reduce to almost zero the waste by utilising off-cuts to produce the heat used in kiln-drying timbers, as well as in the production of our proprietary Vertibat product, which, because it is untreated is a better sustainable alternative to what’s available on the market now. Northland also boasts a lot more agri-business and we’ve been able to supply local capsicum growers and equestrian facilities with sawdust from the milling process of non-treated timbers.”

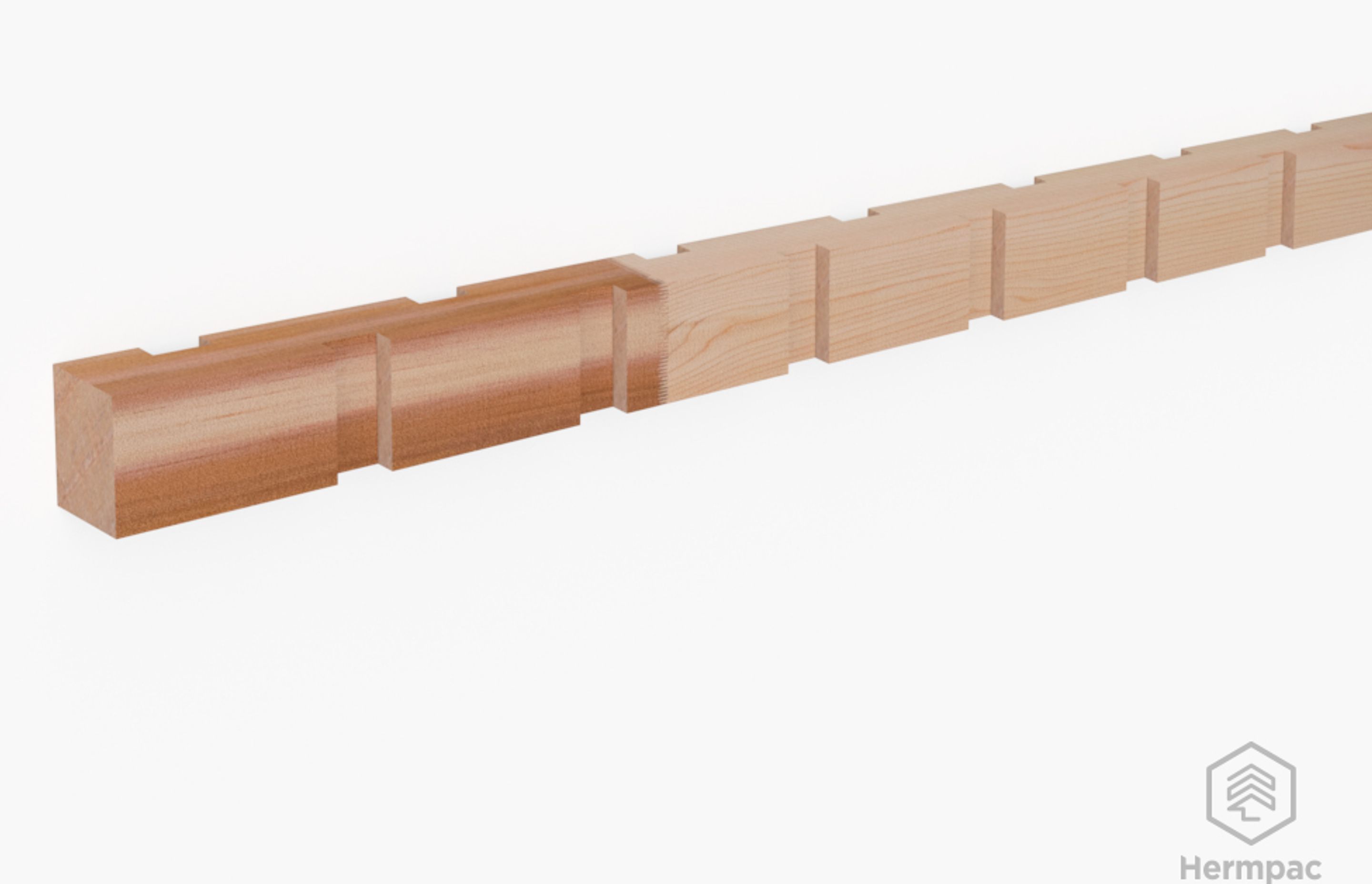

Hermpac also finger-joints off-cuts and damaged pieces of timber into weatherboards, producing a stable product suitable for a painted finish.

“We are New Zealand’s largest importer of timber products and offer a comprehensive range along with the expertise and experience to offer alternatives if the specified product isn’t available for some reason. All of our Hermpac profiles are offered in multiple timber species and are available through leading timber merchants.”

Learn more about sustainable timber products for use in your next project.