Raising the roof

Written by

18 May 2020

•

4 min read

As a rule we don’t tend to spend too much time thinking about the roof over our heads unless, that is, there’s a maintenance issue to be resolved. Fluctuations in seasonal weather patterns and normal wear and tear can play havoc with a roof, which is why it’s always good to carry out periodic checks to see if there is any damage.

Now there’s a roofing system designed to mitigate the usual suspects—water ingress, insufficient ventilation—and provide increased thermal and acoustic performance at the same time.

“Tricore is an advanced roofing system that features three separate components designed to work in concert to provide maximum efficiency,” says Angela Duthie, Dimond Roofing Specifications.

“The Tricore system comprises a prefinished lining sheet, the Tricore perforated roof rail, efficient underlay and a choice of Dimond roofing profiles for the top sheet. Each component has been chosen to provide a specific purpose, which when combined ensures Tricore effectively and efficiently stands up to New Zealand conditions.”

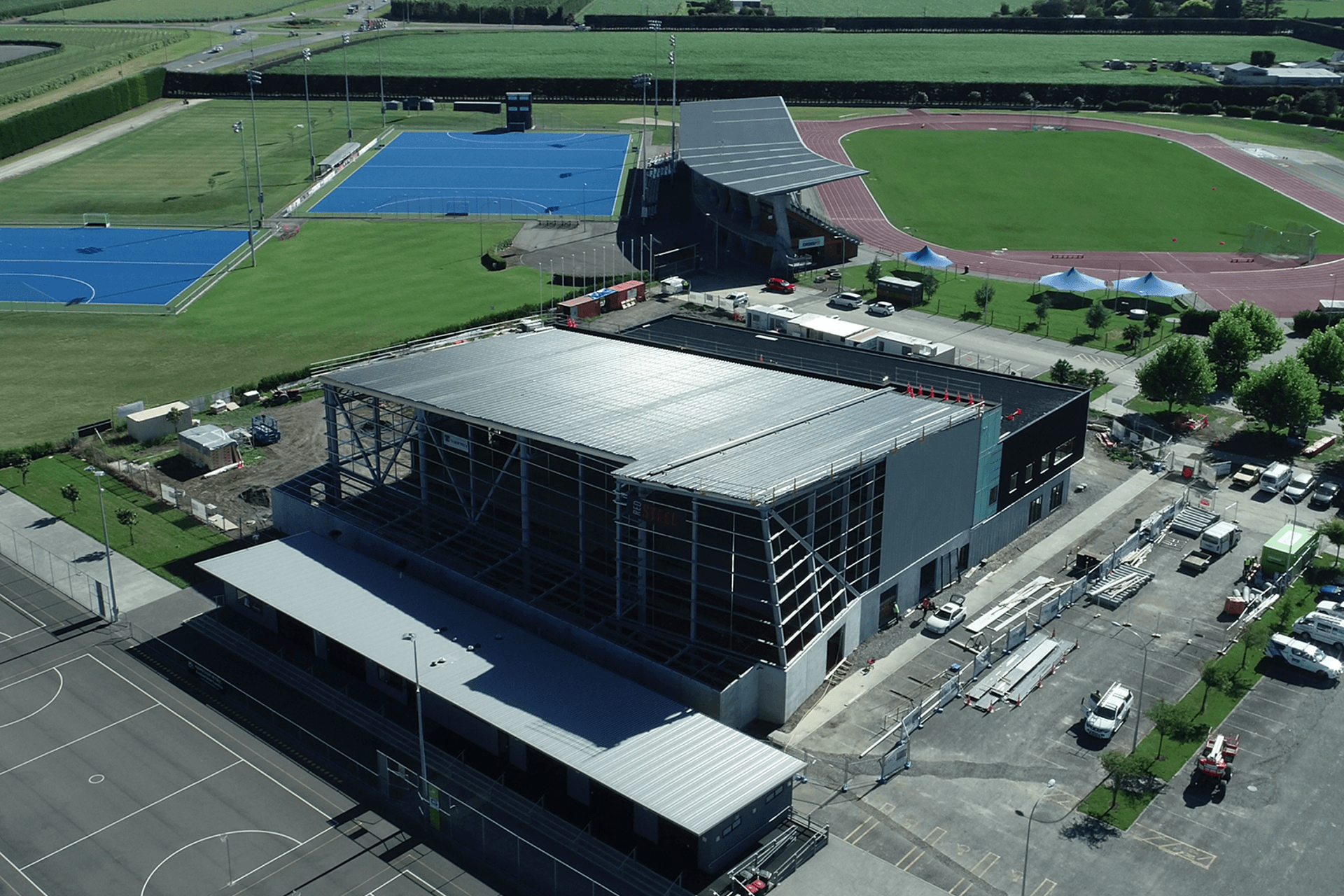

North or south: a roofing system for the nation

“Because Tricore is a modular system, each of the components can be customised to suit regional weather conditions. For example, we use Enertherm PIR insulation board, which can be specified in thicknesses from 50mm up to 140mm depending on the thermal qualities needed. Similarly, the system can be used with virtually any of our roofing profiles for a finished look that perfectly matches the architectural style of the building.”

Angela says Dimond Roofing carried out a significant analysis of potential options prior to launching Tricore in 2018 and the results drove this innovation down a very clear path.

“Using hygrothermal computer modelling, we undertook comparisons of the moisture/humidity performance for these options, simulating conditions in both Auckland and Queenstown over the period of a year using NIWA climate data. Significantly, the options showed that by utilising an air space under the top sheet, relative humidity barely topped 90 per cent on just a small percentage of days across the 12-month period, whereas, without the air space, relative humidity exceeded 90 per cent for two thirds of the year.

“It is known that prolonged exposure to levels of relative humidity exceeding 90 per cent creates a high risk of premature corrosion to the steel top sheets. Based on these findings, the decision to include an air space under the top sheet of the Tricore insulated roofing system was obvious.”

How it works: Ventilation versus Vapour Barrier

“As any New Zealand homeowner knows, condensation can be a real issue. When that condensation occurs in the roof cavity it can negatively impact the effectiveness of insulation, which is why, traditionally, some form of vapour barrier is included. However, no vapour barrier is 100 per cent reliable as penetrations invariably occur,” says Angela.

“The Tricore system employs a perforated roof rail that creates an air space between the roof sheet and the insulation board (which has a high-quality underlay covering it) so that when condensation forms on the underside of the roofing top sheet, it is subjected to passive air movement within the air space. This works to dry out the condensation rather than allowing it to accumulate. The air movement is a natural process driven by the difference in air pressure between the eaves and ridge and thermal buoyancy within the air space.”

Benefits of using the Tricore roofing system

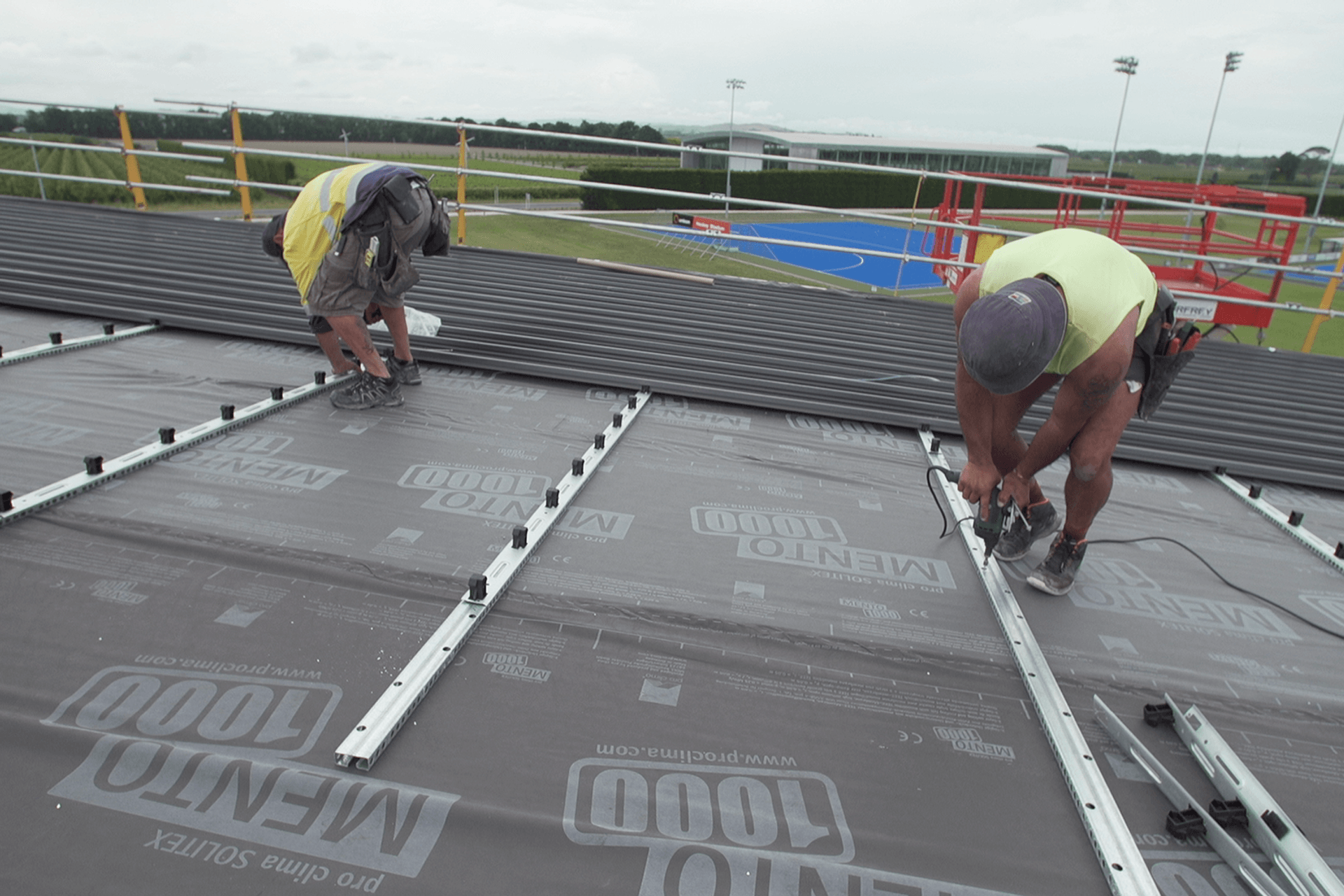

“The benefits of using Tricore are many, starting at the construction phase with the installation of the NPM 900 lining sheet—the first component in the system. Pan-fixed to purlins for rapid enclosure of the building, once installed mechanical and electrical first fix can be carried out at the same time as the remainder of the roofing system is being installed. This greatly speeds up the construction process as activities can be sequenced in parallel.

“Additionally, once the lining sheet is down, the building is weather secure, from a roofing perspective and if unforeseen circumstances cause a cessation of work, the building is closed-in. Ongoing roof maintenance, too, is easy, as the roof sheet can be replaced if damaged without any need to move or replace the insulation layer. All of the components also carry a 15-year warranty.”

Angela says Tricore has been designed for commercial and residential use, where it can be teamed with any Dimond Roofing profile, including the Kiwi favourite, Corrugate, or the stylishly modern Heritage Tray profile. The company is happy to provide roofing contractors with guidance or specific training on the installation of the product to Building Code requirements.

Learn more about the Tricore roofing system.