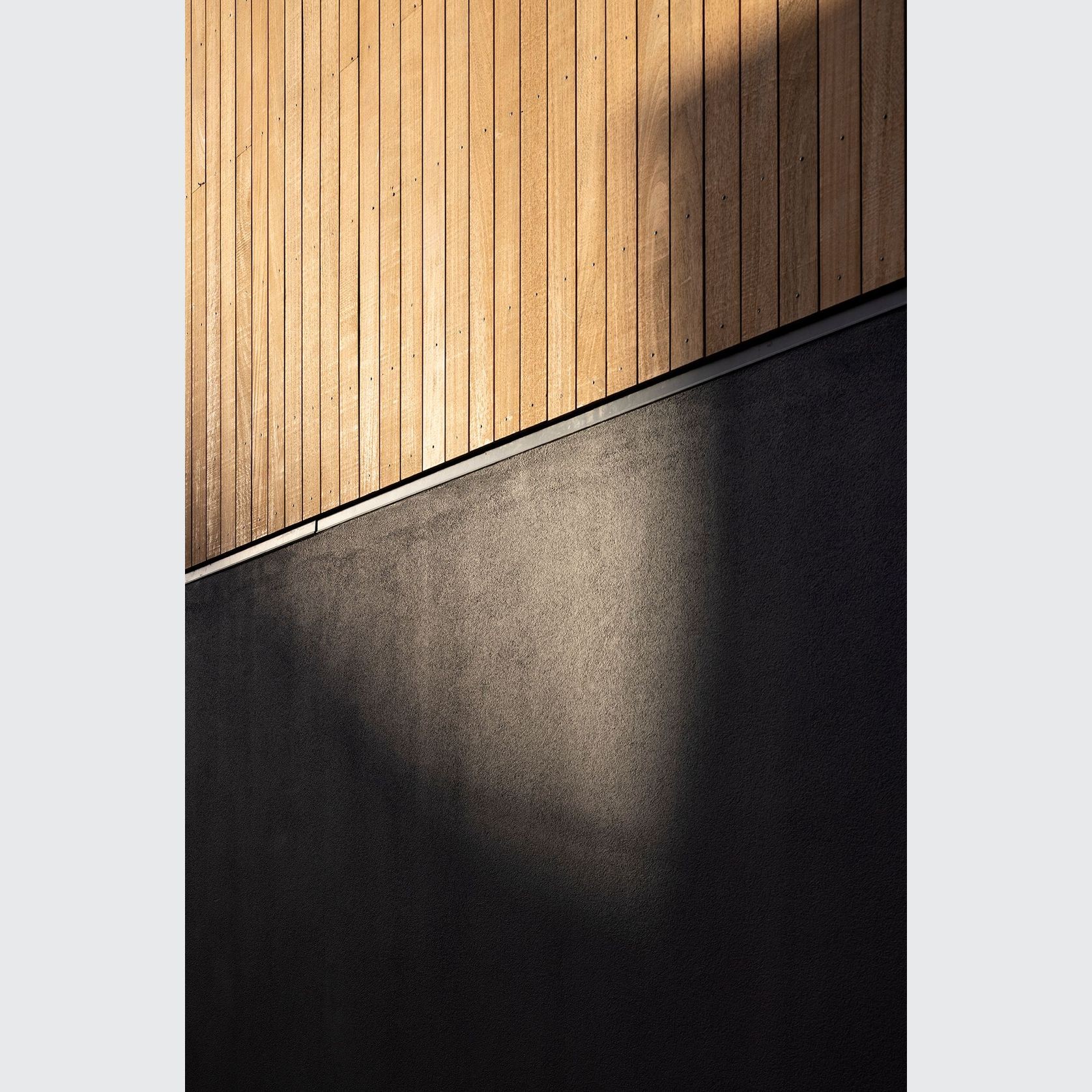

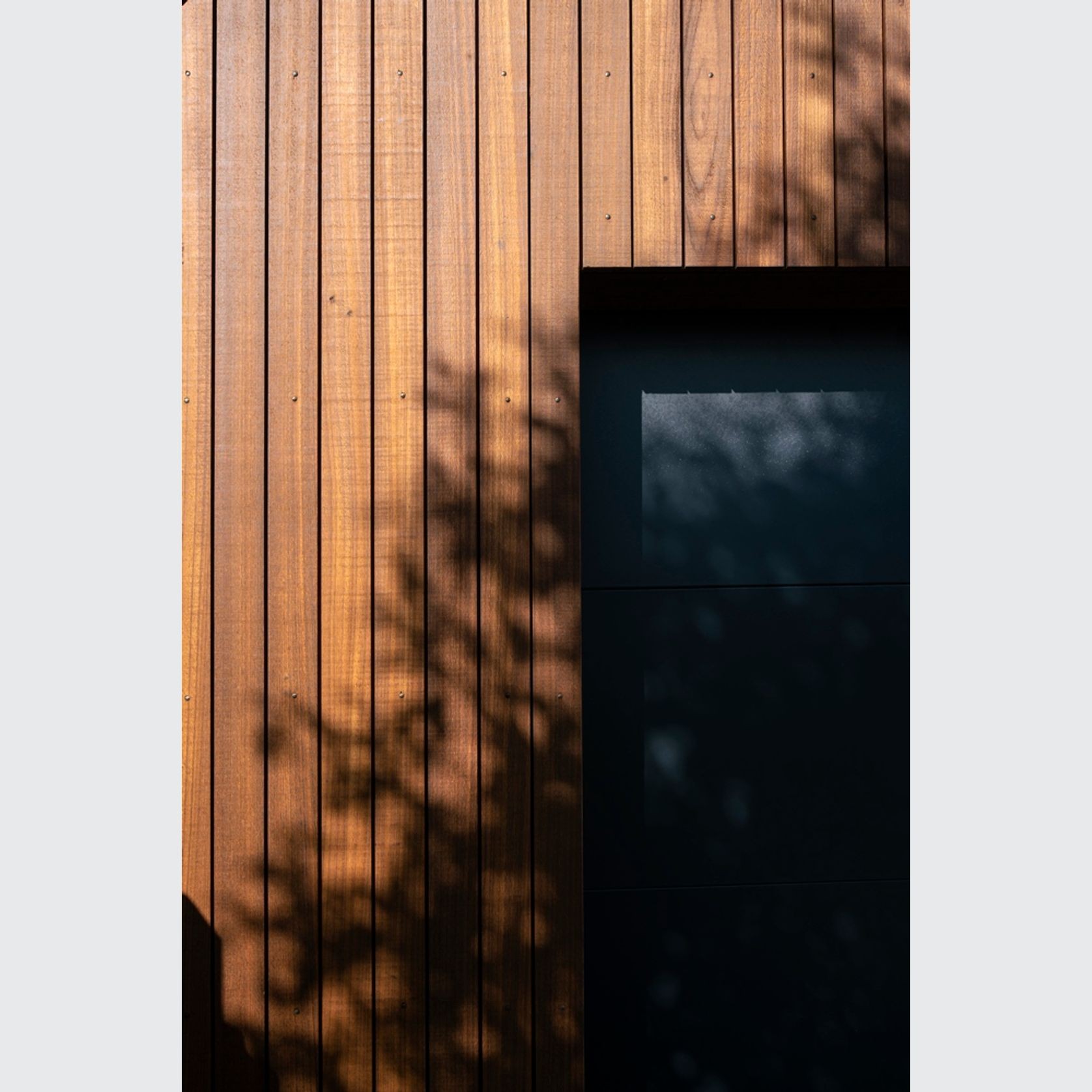

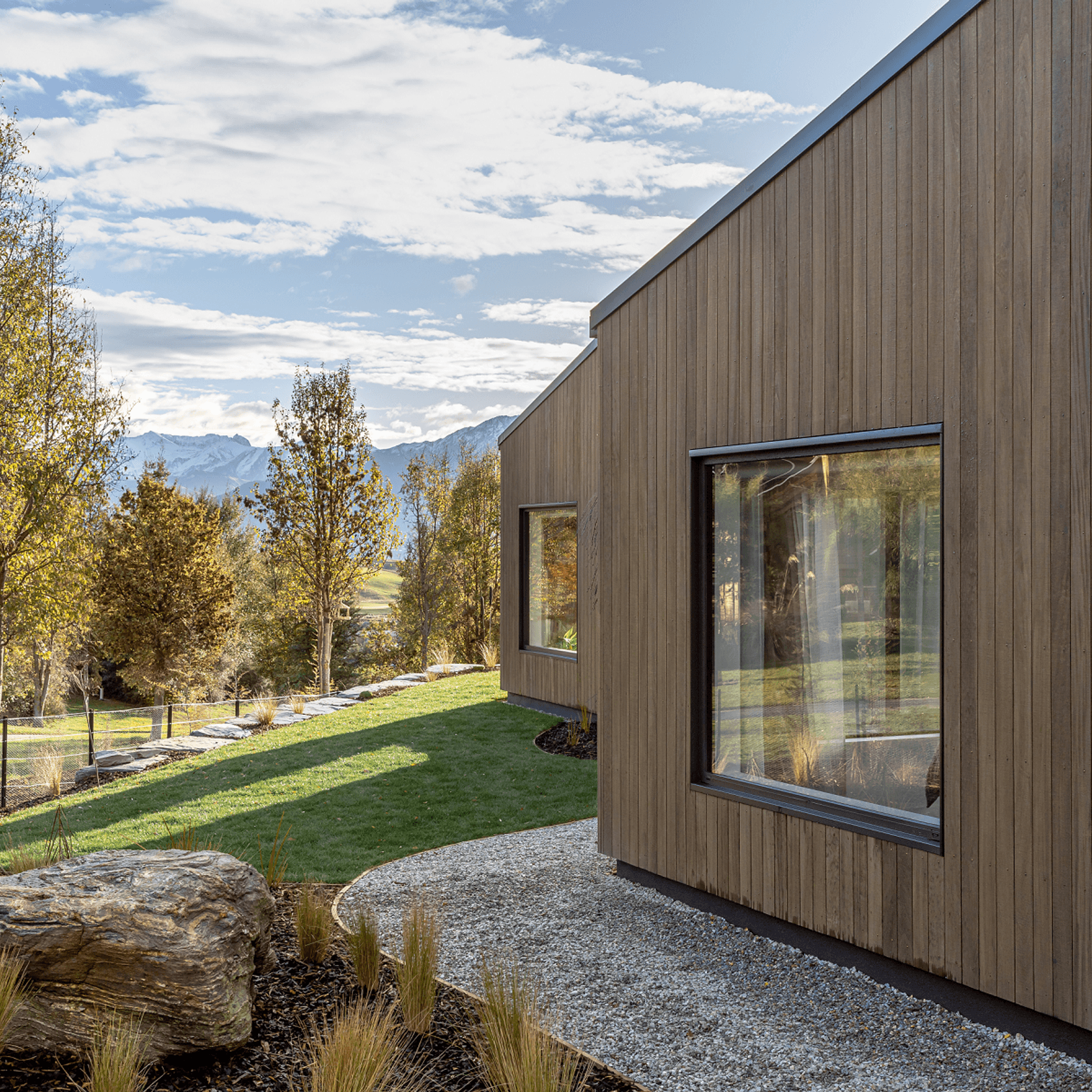

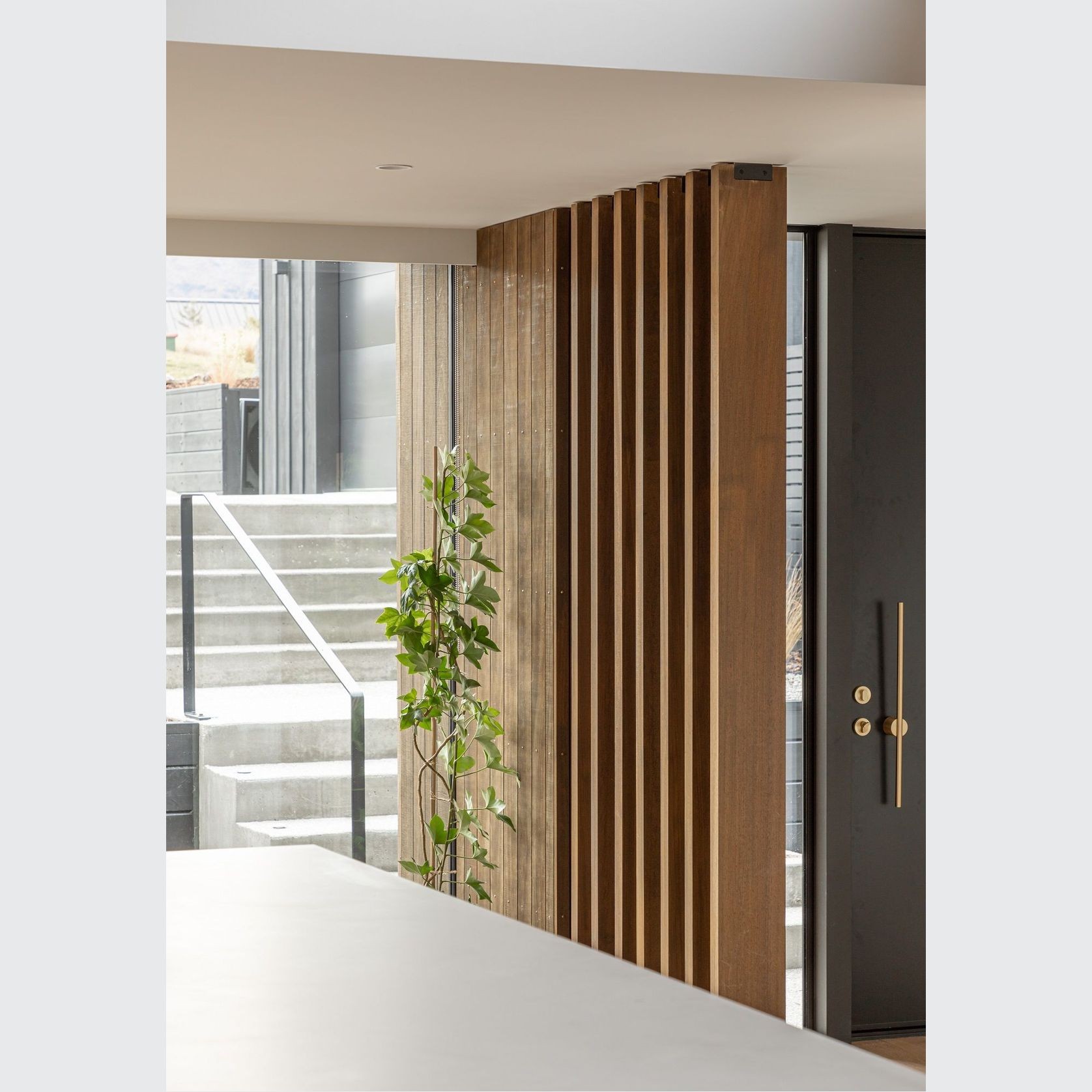

Truwood® Thermally Modified Cladding

RK TimbersDetails

- CategoryTimber, Timber Cladding

- RangeTruwood®

- BrandTruwood®

General

- Type of useCommercial and Residential

Scope of use

Features

Specs / Details

Performance

Downloads

Projects featuring Truwood® Thermally Modified Cladding

More from RK Timbers

About the

Seller

For four generations, the inherent qualities and creative potential provided by timber have inspired us and driven innovation at RK Timbers.

If you need proof that the inventive spirit of Kiwis is alive and thriving, you only need to look at the way timber is being used to create spectacular spaces and objects throughout the country. We’re enormously proud to be involved with many of New Zealand’s finest builds, helping architects, designers, artisans and owners take their concepts from paper to the highest standards of craftsmanship.

- ArchiPro Member since2016

- LocationView all locations (+1)

- More information