Botany Toyota Workshop & Showroom

By Carter Holt Harvey

Project: Toyota Workshop And Showroom, Botany

Building Location: Botany, Auckland

Owner: Howard Properties

Architect: Alistair Scott, Woodhams Meikle Zhan Architects

Engineer: Sophie Shi, Blueprint Consulting Engineers

Fabricator: Timberlab Solutions

Builder: Savory Construction

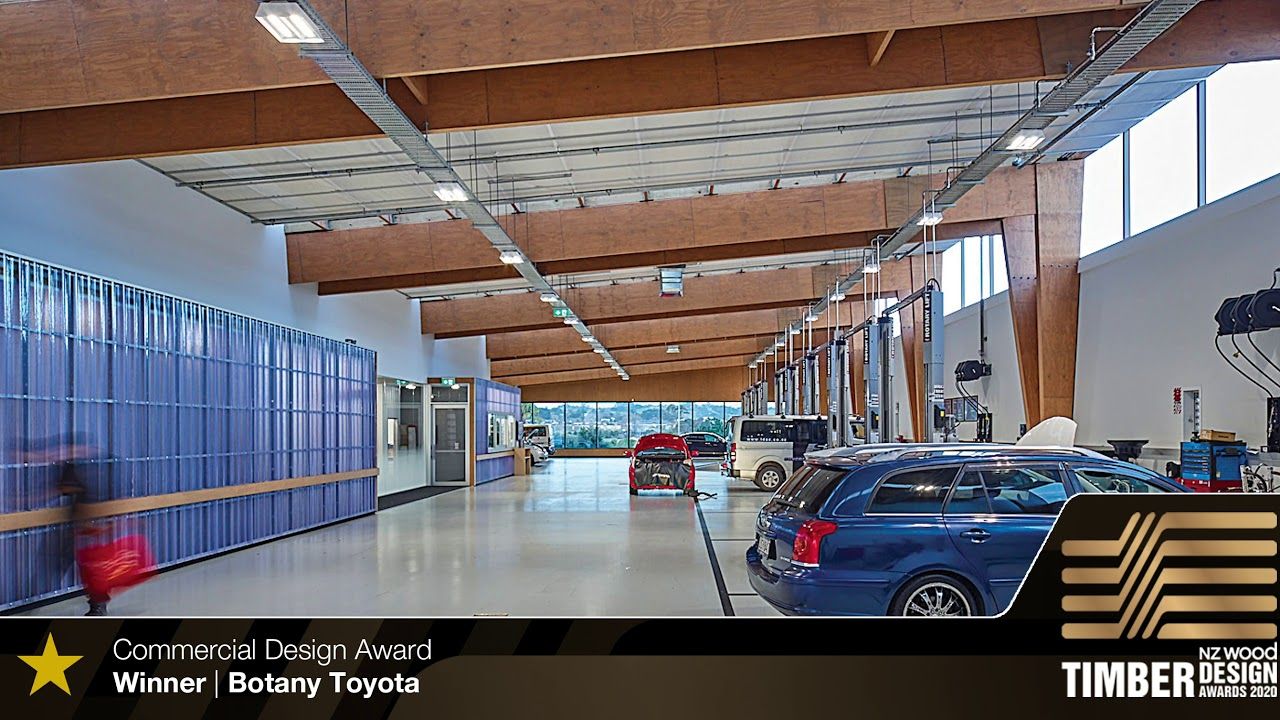

Engineered wood products add warmth and character to car workshop and showroom.

When Alistair Scott, Architect for Woodhams Meikle Zhan Architects (WMZA) was tasked with designing a new showroom and workshop for Toyota, he started with understanding the brand. His research brought him to Toyota’s Global Vision, which is represented by an image of a tree. The image of a tree has been used by Toyota to symbolize their vision from 'roots to fruits.' The tree is a symbol of natural strength, as something that is useful and long-lasting, that continues to grow and flourish year after year.

WMZA have typically designed steel structures, however for this project a different approach was taken, as the client had a desire to use natural, sustainable products where possible. The metaphor of the Toyota Tree was fitting, it was evident the building needed to utilise a timber structure to tie in with the client’s desire to build a unique, sustainably focussed building that has warmth and character.

The project’s design was finalised with essentially two big ‘sheds,’ one for the showroom to house new cars and one for the workshop to service vehicles. The final design incorporated a series of mono pitch portal frames at 8.4m bay spacings to suit the work bays required and the size of the hoists in the workshop. As Alistair Scott, Architect, describes, the idea was to “create a space that felt like a gift box, a container to showcase Toyota’s vehicles to their best”. As such, large wooden portal frames were agreed upon to be the best solution. The workshop portal frame required a clear span of 20m, the showroom 17m.

The exposed timber aesthetic throughout the buildings was used to create a natural feeling and added warmth to the spaces, in contrast to the hard surfaces of a workshop, cars, paint and metal. Timber based internal wall linings were also used to add to the warmth of the space.

Futurebuild® Laminated Veneer Lumber (LVL) was chosen as the material to create the portal frames. As a structural building material made from renewable plantation pine, Futurebuild LVL is a natural choice in projects that have an environmental focus. Futurebuild LVL is sourced from renewable plantation Radiata Pine forests, has the Declare label for Red List Free and can be supplied Forestry Stewardship Council (FSC®) certified. To further add to the sustainability focus of this project solar panels were added to the roof.

The roof linking the showroom and workshop was essentially an “upside-down” house roof and canopy and it required an efficient structure to span across the space, one that is lightweight, and to help create lots of natural light. Again, Futurebuild LVL was the ideal solution for this. hyCHORD® was used in prefabricated roof trusses for this section of the building. Futurebuild LVL trusses are a lightweight option when compared to hot rolled steel. Cost was considered and despite the complexity of the trusses, the LVL solution still compared well to a similar structure built of steel.

The Engineers on the project, Blueprint Consulting, got in contact with Futurebuild LVL’s in-house engineering team and utilised our free preliminary design service as well as the engineering design software, computeIT® toolkIT. Having never designed an LVL portal before, the help from Futurebuild LVL’s engineers and software was useful, and Blueprint’s engineer, Sophie Shi, was able to become confident in a timber solution for this project. Sophie comments, “my favourite part of the design process was using the computeIT software. Before doing the engineering, the preliminary design service gave a good idea of the size and beam of a column that can be used.” The comprehensive Specific Engineering Design Guide, downloadable from the Futurebuild LVL website, was also used by Blueprint to assist in the design.

The LVL for this project was custom manufactured at the Futurebuild LVL factory at Marsden Point, in Northland, NZ. The longest length produced was 17.7m, with a total of 90m3 of LVL manufactured for this project.

The LVL was transported to Timberlab Solutions, who fabricated and sanded the LVL into the portal frame components. The 17.1m sections were spliced on-site with additional 3m lengths to create the 20m clear span beams.

The portals were placed at 8.4m centres, creating a large open space. The structural solution consisted of two pairs of sloped portal frames, consisting of box columns tapered from 400mm to 900mm with a 90 mm ‘gap’ to suit the slotted rafter. Single 900x90mm hySPAN® rafters were installed on-site together with the addition of cut to length LVL purlins.

The project generated a lot of interest from passers-by as it went up and during the construction phase. The giant LVL portal frames certainly stood out on the busy stretch of a road where the project is located, with the building type being one that is typically done in steel, showcasing the ‘wow’ effect that LVL can have in a commercial building – not just in the finished result but in seeing the speed at which it can be built.

This building was a learning opportunity for the design team and contractors who were used to building steel structures. With the support from Futurebuild LVL’s experienced timber design engineers, they soon realised that the design and construct process was not to dissimilar to other building typologies and that their skillsets were easily transferrable to working with LVL.

A water-based stain was used to finish the LVL, showcasing the grain of timber and retaining the natural warmth of wood in the interior space. The result is a building of character that stands out in a prominent location, with large exposed timber portal frames creating a unique and inviting space. As a result of the success of this project, Alistair Scott says he will be looking at doing a lot more in timber design.

This project was awarded the Commercial Design Award at the 2020 Timber Design Awards.

Professionals used in

Botany Toyota Workshop & Showroom

More projects from

Carter Holt Harvey

About the

Professional

Carter Holt Harvey (CHH) is one of New Zealand’s leading forest products companies, manufacturing and supplying timber, laminated veneer lumber (LVL), plywood and other building products to the New Zealand market. Carter Holt Harvey together with its legacy companies has been a feature of the Australasian timber industry for more than 150 years. Carter Holt Harvey is organised into four business units: Carter Holt Harvey Building Products (CHH Timber), Carter Holt Harvey Plywood (CHH Plywood), Carter Holt Harvey LVL (Futurebuild®LVL) and Carters Building Supplies.

CHH Timber is one of the largest and oldest producers of timber building products across New Zealand. Manufacturing timber across the Kawerau, Kinleith and Nelson Mill facilities, CHH Timber produces brands Laserframe®and Pinex®for use in structurally graded or outdoor timber applications.

CHH Plywood specialises in the manufacture and supply of both structural and non-structural plywood products, with familiar brands such as Ecoply®, Shadowclad®, Ecoply Barrier and Handiply®. These brands are suitable for a range of applications subject to proposed use including structural, exterior cladding, interior lining applications, DIY and packaging among some of the many uses. The brands are specified and used within the New Zealand construction industry by Architects, Builders and DIY professionals. Operating in New Zealand for over 30 years, CHH Plywood is one of the largest producers of plywood in New Zealand and manufactures from its central North Island site at Tokoroa.

Futurebuild LVL offers the largest range of LVL products within New Zealand, which are used in projects across Australasia. Manufacturing LVL in the Marsden Point plant, Futurebuild LVL produces brands hySPAN®, hyJOIST®, hyONE®, hy90®, hyCHORD®, truFORM®, hyPLANK®, edgeFORM®, and hyFRAME® building systems. Futurebuild LVL products are used in applications such as floor joists, beams, rafters, lintels, truss chords and purlins in construction of residential, commercial, industrial and rural buildings, subject to design verification.

- ArchiPro Member since2020

- Locations

- More information