The Mashery

By Design Production Limited

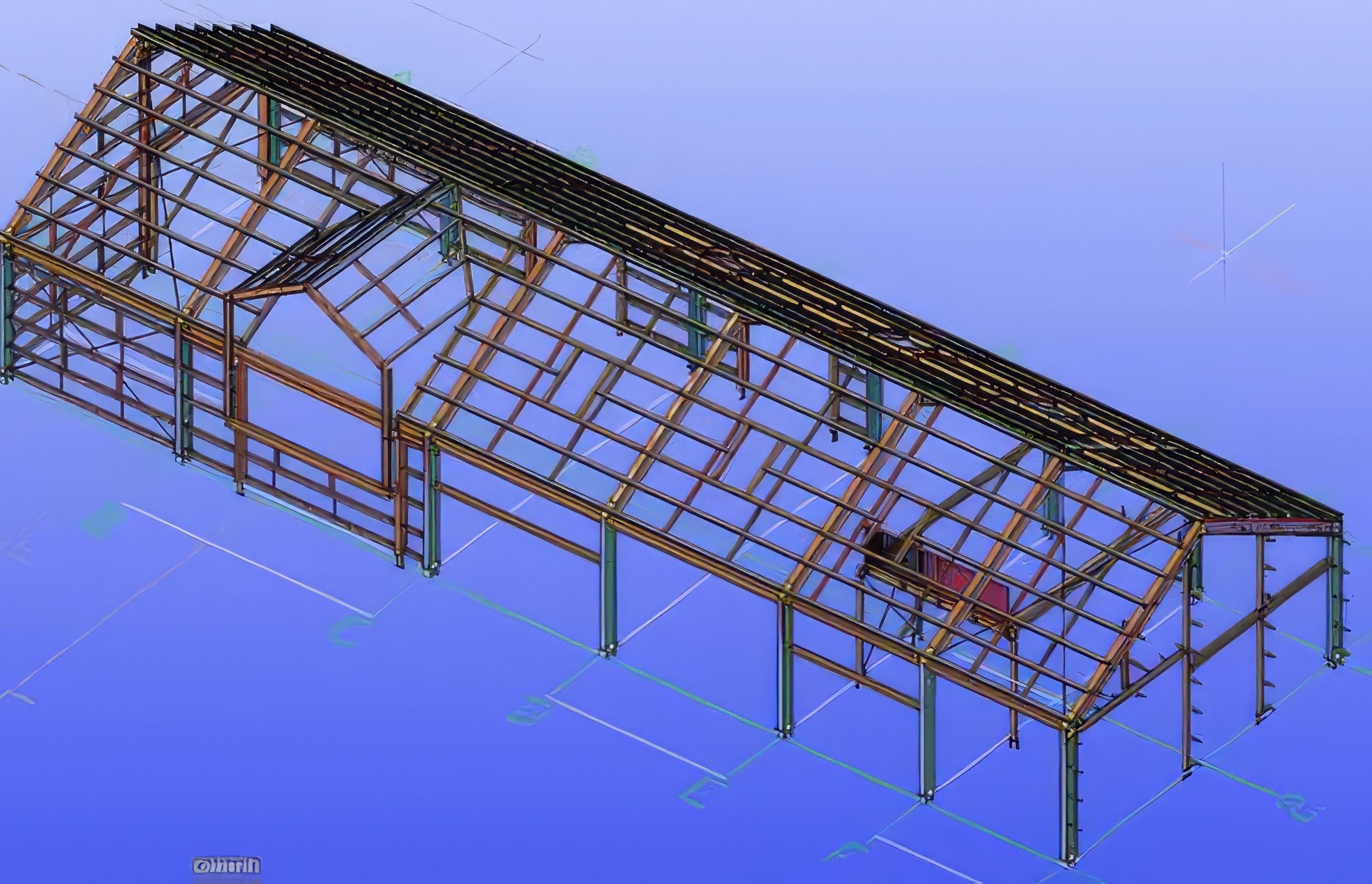

Our part of the project involved the exposed steel structure, purlins, girts and a few architectural items for The Mashery distillery in Waiheke.

Challenges/complexity and our approach to it:

Shipping an entire structure to Waiheke Island put quite a bit of pressure on us as we could not account for loose points in either the design, fabrication or install processes. In order to avoid these, we worked closely with the consultants, builders and client to be able to anticipate issues with the install. We coordinated some modifications to the original steel connections in order to give us adjustability and facilitate the installation. Some members such as the steel portals were split in sections to allow the parts to fit into the galvanising tank as well as transporting them around following the NZTA limits for over-dimension loads. Design Production also provided dummy plates for the cast-in fixings, while working closely with the builder to facilitate the install of the steel columns. To assist us with the installation, we counted with our access equipment sent to Waiheke, such as: Scania with truck mounted crane; All-terrain 20T Kobelco Crane, Skyjack 16m Knuckle Boom, Skyjack Scissor Lift.

Contractor/builder: Envoy Construction

Architect: Izzard

Town/city: Waiheke Island

Size (in steel): Approximately 17 tonnes

Professionals used in

The Mashery

More projects from

Design Production Limited

About the

Professional

Based in Auckland’s industrial heartland, Penrose, Design Production sets the bar in structural steel fabrication and architectural metalwork, using first-of-its-kind robotic welding technology, and advanced 3D CAD software.

Brothers Cameron and Ryan McAuley established Design Production in 1997 from a deep connection to the transformative process and creative capabilities of steel; creating something of function, longevity and beauty from a few lines on a drawing.

Employing the principles of craftsmanship, at-scale, have fostered a reputation of reliability, attention to detail, exceptional quality workmanship, friendly and accommodating service, and the cultivation of long-term relationships.

We have seen 25 years of growth and investment in our people, processes, plant and equipment, and are currently housed in a 3000m² factory using the latest structural steel robotics technology and 3D CAD software.

As a leader in structural and architectural steel fabrication, ongoing investment in technology, commitment to our clients, and compliance with industry standards have allowed us to become the fabricator of choice for many large contractors.

- Year founded1997

- ArchiPro Member since2024

- Follow

- Locations

- More information