A cladding revolution: Euramax pre-coated aluminium

Written by

16 July 2017

•

4 min read

Powder coated panels and composite panels have, for a long time, been a popular choice for commercial cladding, due to the very limited steel options available for this sort of scope. While powder coated panels have their benefits, the disadvantages are numerous, Ambro Metals’ architectural team Stephen Davies and Adrian Ward say.

“Powder coating can be limited in colour selection and consistency in finish quality. This compromise can limit the lifespan of the installed product,” Stephen says. “Because powder coated panels can’t be refolded after colouring, if any variations are needed, this can lead to significant and costly delays in the construction process waiting for panels to be re-coated in their entirety to account for a miscalculation”.

Aluminium Composite Material (ACM) panels have been the other commonly used cladding option in New Zealand, but they also pose significant issues and require silicon joins. These are vulnerable to shrinking and therefore have the potential to allow water to penetrate the building envelope, which will cause damage to the building’s structure.

Ambro Metals, exclusive suppliers of EURAMAX pre-coated aluminium in New Zealand, have now opened a vast range of new possibilities in 0.70 to 2mm thick pre-coated aluminium. This high quality and enormous range in product selection has never been available to the New Zealand market before, especially in pre-coated heavy gauge aluminium. “This is a EURAMAX product that we, as architectural roofing and cladding material supply specialists, can provide here in New Zealand. Our network of architectural profile specialists are able to install EURAMAX material with hidden fixings for heavy capping and cladding systems,” Adrian says. “It provides an

elegant architectural look without thick silicon joins, panel deviations or disrupting installation lead times – not to mention the superior quality.”

Aluminium’s high strength-to-weight ratio is a significant benefit when considering EURAMAX, which is manufactured from corrosion resistant aluminium alloys. “It’s a unique characteristic of the material that allows architects to meet stringent performance specifications while minimising the dead load on the building’s supporting structure,” Stephen says.

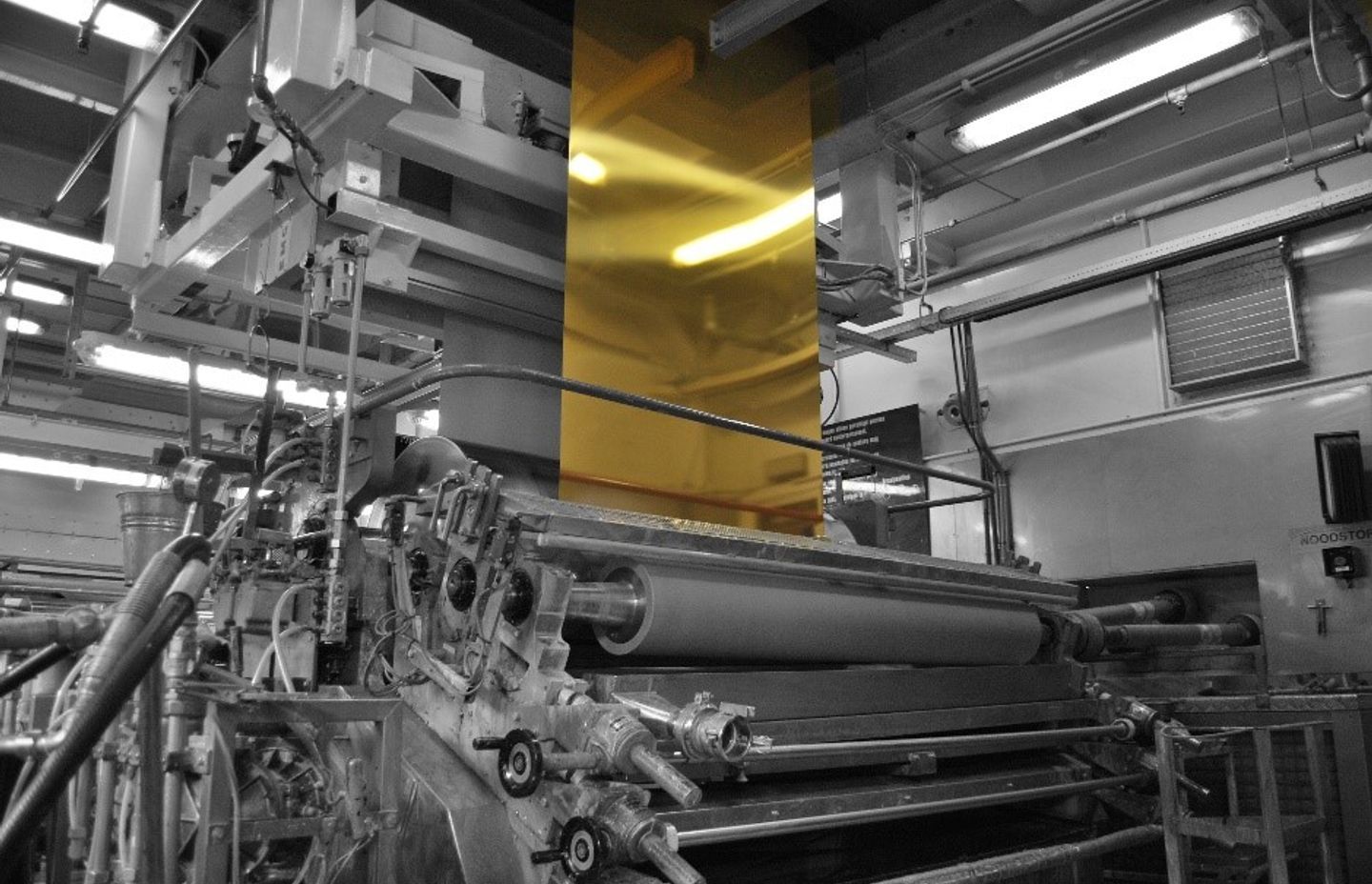

The pre-coating process is an in-depth one that has been specifically tailored for New Zealand’s harsh climate. “EURAMAX aluminium first goes through a stringent cleansing process that cleans the bare aluminium to remove any impurities,” Adrian says. “It then has a non-chromate etching applied, followed by a primer layer prior to colouring. Once it has been primed the first layer of colour is applied with an advanced closed loop, rolled-on process and repeated for multi-layered coatings or design finishes. Because the paint colours are rolled on you get a far higher quality coating with greater consistency and film build than you do with powder coating.” The material can then be formed after the coil or sheet has been coated.

The range of colour options are also far wider than what is available with powder coating, and incorporate a variety of finishes including single and metallic tones, along with flip tone Mica colours that create the effect of the building changing colour as the sun moves around it!

EURAMAX also provide a vast range of high end design finishes mimicking weathering metals, stones and timber. This allows designers a new level of affordable creative freedom with superior quality not previously possible.

“Aluminium has many benefits, but one of the key aspects is that it is environmentally friendly,” Stephen says. “There is an abundance of Bauxite, the mineral aluminium is made from, around the world so it’s a freely available material and is highly sustainable, being 100 per cent recyclable at the end of its life.” EURAMAX’s water based PVDF paint systems are heavy metal and chromate free and are also devoid of VOCs, which are combusted while curing during the painting process.

Suitable for residential roofing or large-scale commercial cladding, EURAMAX products are creating new hype and design possibilities with the technological advancements it provides. “In regards to roofing, EURAMAX is an affordable, high-quality, low maintenance option that is far superior to any other painted product until you get into the leagues of copper and Terne,” Adrian says. “We have tailored a specific coating system to tackle New Zealand’s uniquely harsh environment.”

“We’ve had a big gap in the roofing and cladding market that drops from the very high end non-ferrous metals down to coloured iron steels, and in commercial cladding we’ve had very limited options, each with its own disadvantages. EURAMAX is bridging that gap with an extremely flexible, durable product that allows for a new level of creative freedom.”

Get in touch with Ambro Metals on ArchiPro here to find out more about EURAMAX.