A new advancement in slab edge insulation

Written by

14 May 2024

•

5 min read

Reliability, performance, code compliance and sustainability are just some of the aspects to consider when specifying for a construction project. Launched last year, Allied Concrete’s SuperSlab+ innovation is a proven solution that delivers on each.

Transforming foundations with unmatched performance and certified quality

“Allied Concrete’s SuperSlab+ system sets the industry benchmark for insulated foundation solutions, offering unparalleled thermal efficiency, robust durability, and a steadfast commitment to sustainability,” says Nick Gifford, Allied Concrete’s national strategic sales manager.

Developed in collaboration with QuickSet, the SuperSlab+ system is designed for applications ranging from house slabs to shed floors, as well as small commercial buildings and warehouses. It provides edge-insulated concrete foundations that exceed industry standards, ensuring superior thermal performance, enhanced durability and consistent interior comfort. Whether your next project is in Zone 1 or Zone 6, with or without underfloor heating, SuperSlab+ makes it stress-free to navigate the H1 building code changes.

“Certified by CodeMark and appraised by BRANZ, SuperSlab+ exceeds the rigorous R-value requirements of the H1 building code, ensuring your construction projects are not just compliant but ahead of industry standards,” says Gifford. “SuperSlab+ leverages our partnership with QuickSet to deliver comprehensive H1-compliant solutions for slab design and construction. This ensures you meet the latest H1 standards effortlessly, regardless of your project's location.”

For those who prefer the tried-and-tested traditional boxing methods but seek the advancements of modern solutions, QuickEdge excels in seamless compatibility with traditional boxing and existing hold-downs. It offers unbeatable cost-effectiveness, requires no additional finishing after installation, and provides supreme durability to endure construction sites and lively home environments.

Read more: Why choose SuperSlab+ with QuickEdge? A deep dive into its unmatched advantages

An eco-friendly solution

Backed by certifications from CodeMark and BRANZ, SuperSlab+ is also a sustainable solution for the construction industry.

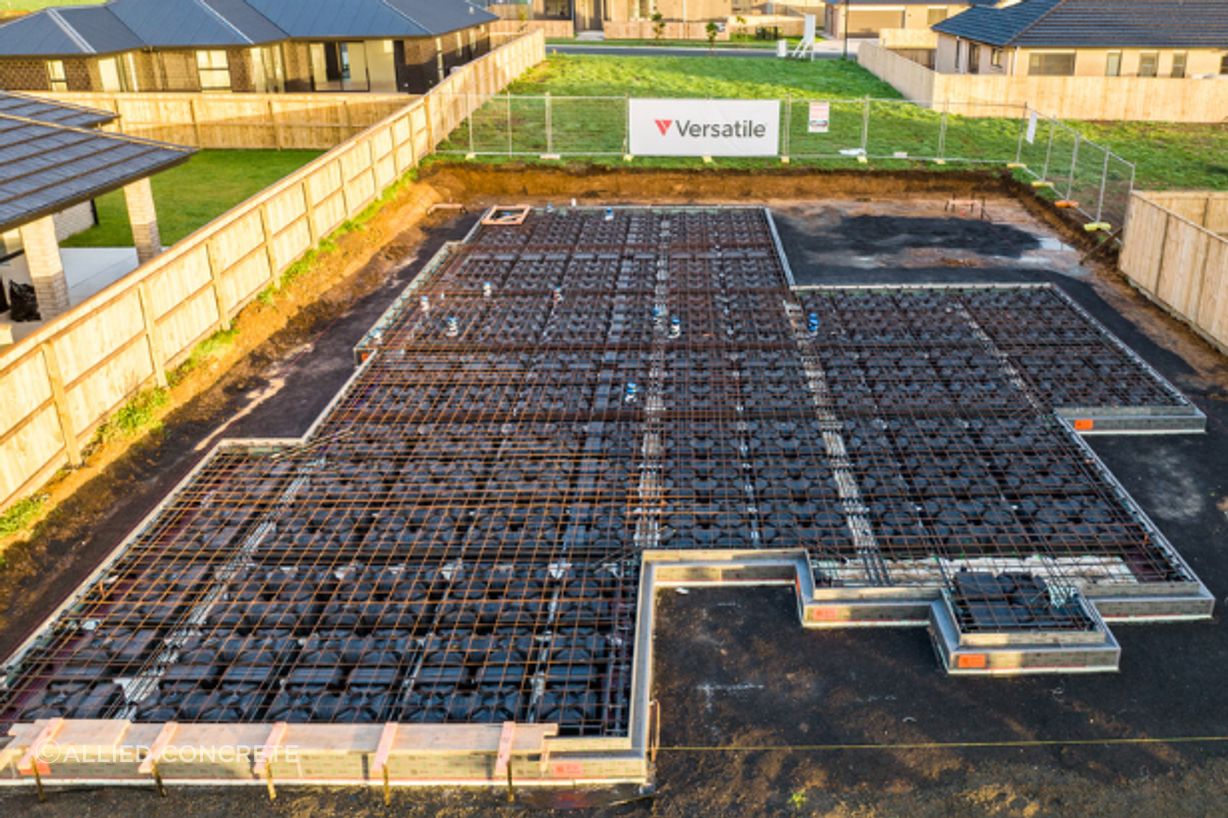

By integrating technologies like Ecrete – an innovative concrete mix that lowers a project’s carbon impact without sacrificing strength and durability – and QPOD – a locally-manufactured foundation system made from recycled material and is 100 per cent recyclable – SuperSlab+ embodies Allied Concrete’s commitment to a greener future.

“SuperSlab+ gives you the confidence of an engineered raft slab while at the same time having the added benefits of knowing that you are minimising your carbon footprint by using a combination of solutions that offer a more sustainable option versus traditional raft slab construction,” says Gifford.

Cost-savings for your next residential or commercial construction project

“One of the benefits of SuperSlab+ is its CodeMark certification when used on ‘good ground’,” says Gifford. “By utilising the design details available on the Allied Concrete website, you can specify an engineered slab without the cost of engaging an engineer to design or provide inspections. This is a considerable saving, which will provide additional savings on the build cost – particularly with the current environment the residential market is in.”

By leveraging QuickSet’s insulated, internally-braced and permanent formwork system for raft foundations that can exist either as a fully-insulted system or as edge insulation alone, SuperSlab+ also saves on time and materials thanks to no time wasted on stripping or removing formwork once the concrete is poured.

The benefits of SuperSlab+ slab edge insulation

- Minimal excavation

- Simple and improved build process for foundation

- Suitable for poor sites with low soil-bearing capabilities

- Improved thermal performance (R-value)

- CodeMark certified and BRANZ appraised

- Some of the materials use recycled plastic

- Insulating and self-extinguishing

- It can be tailored to any land classification

What else should you know about SuperSlab+?

SuperSlab+ can be used on sloped sections and be built on sites with an allowable bearing pressure from 50 kPa (50 per cent of the standard 100 kPa ‘good ground’ stated in NZS3604) depending on the building type. Other ground conditions require a specific engineering design (SED).

“Pod floors fully suspended on piles over very poor ground, deep topsoil or peat can be very economical as the beams formed by the pods are able to span between piles with minimal extra reinforcement.”

In terms of weight, a typical SuperSlab+ system is designed for 2.5 kPa – the garage floor loading of a house. Specifically-designed slabs can perform up to 10 kPa, however, reinforcement and topping thickness will vary for these designs.

Installation of SuperSlab+

With no special training required to install a SuperSlab+ system other than being a licensed building practitioner, this solution is accessible for projects of all sizes. Plus, Allied Concrete can provide onsite training if required.

For experienced contractors with the correct equipment, only around three days are needed to install the SuperSlab+ system – a faster solution than conventional footings, which can take around two weeks to complete.

If you’d like to learn more about SuperSlab+ and how it can bring proven benefits to elevate your next residential or commercial construction project, get in touch with Allied Concrete or explore products and projects on ArchiPro.