About Plywood

Plywood is a product made up of numerous thin strips of wood, known as veneers.

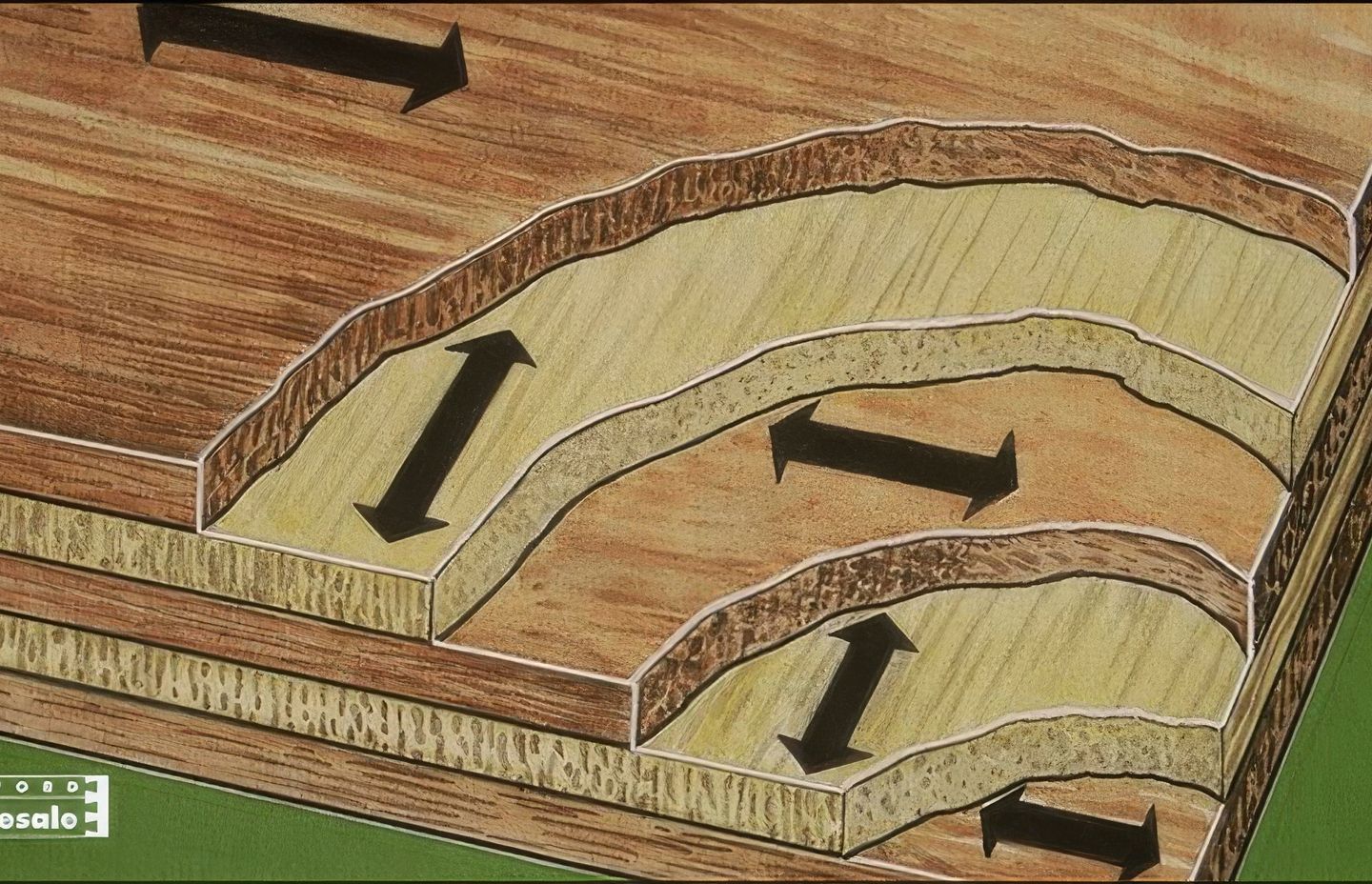

Each veneer sheet is laid on top of each other with the grain of each alternating sheet running in opposition direction and bonded with glue into a plywood sheet. This method of construction creates a very strong and versatile man-made timber material which is less susceptible to expansion and shrinkage.

The majority of plywood is made from an odd number of layers, called plies (typically 3, 5 or 7), with an equal number of plies on each side of the center ply.

One side of the plywood sheet is known as the “face” which is normally the side which would be seen in most applications and is generally the superior side. The other side is known as the “back” and is generally not as appealing and maybe rough. You can purchase plywood that has two goods sides for those applications where both sides of the sheet will be visible.

General Information

Plywood is available in various lengths, widths and thicknesses. Standard dimensions for length are 1800mm, 2400mm and 2700mm. Width is generally 1200mm. Sizing can be imperial (2440mm) or metric (2400mm).

Thicknesses are available from 3, 4, 6, 7, 9, 12, 15, 17, 18, 19, 20, 21, 25 and 28mm. Thicknesses vary between different manufacturers and products.

When specifying plywood the following information should be supplied:

- Dimensions

- Type of Plywood

- Structural Rating (where required)

- Veneer Grade

- Glue Bond

- Treated or Untreated

Perforation and Laser Cutting

Many panel products can be perforated with either holes or slots which allow the panels to be used in areas where sound attenuation is important. Areas where this may be applicable include internal ceiling and wall linings in schools, public halls, gymnasiums, offices and other commercial premises. Most panel products can be perforated with decorative timber veneers being the most common. A standard range of hole sizes and patterns allows specifiers to achieve their sound requirements for any given area.

Laser cutting allows the flexibility of design to come to the fore as each project can be custom designed. Laser cut panels can be used as room partitions and feature panels.