Accoya Plant and Project Tour 2019

Nine intrepid Architects and Designers from various practices around New Zealand signed up to a whirlwind tour to the Accoya factory in The Netherlands. The aim was to gain a better understanding of Accoya® timber, how it is processed and tested, and to see first-hand some outstanding established projects where Accoya® has been specified and used to great effect.

With Laurens Notenboom, our faithful Dutch Tour Guide from Accsys Technologies at the helm, we spent the first afternoon on a walking tour around the bustling canals and dock areas of the downtown Amsterdam waterfront. Once we learnt the art of not stepping into the cycle lanes, and subsequently being collected by a peddling local, things became a bit easier and bit more composed.

The Dutch are great believers in embracing the outdoors and as such have excellent examples of functional (and sometimes quirky) public space infrastructure. Lots of seating, sculpture, boardwalks, and floating pontoons that often incorporate timber to give a warmer and softer appeal to these spaces. A great example where Accoya is used is the 800 metre long floating Oosterdok project, near Amsterdam Centraal. The evening was spent in a few city cafés getting to know our fellow travelling companions on the tour, over a few local beers, gin & tonics and bitterballens.

Day two kicked off at the world class Park 20/20 business park complex, near Schiphol Airport. This innovative precinct comprises of a number of individual but, integrated buildings that are built around a sustainable and low energy-usage design model. Due to Accoya®'s leading environmental credentials, it is used in numerous applications ranging from interiors to exteriors including cladding, soffit linings, seating and outdoor structures.

Later that morning, we piled back into our 16 seater bus, and headed north via a town called Apeldoorn which boasts a state of the art Olympic rated Velodrome (the 2017 track cycling World champs were held here). The cycling track surface has been re-laid with Accoya® and because of its natural stability and ability to withstand large seasonal temperature variations, Accoya® performs outstandingly well and provides superior reliability and a fast smooth surface. As such they were very keen to point out, a number of world record times were achieved.

We ended the day in Assen, in the northern part of the country where we took in a few more sites including the very imposing Accoya® sculpture of ‘Hannes’ the Great Dane, who, according to local folklore was the historical protector of the region against invading Norsemen and Vikings.

Day three, we travelled south-east via the Dieren railway station bridge which is another great example showcasing natural uncoated Accoya, utilising its unrivalled durability and low maintenance properties. At midday we arrived in the city of Arnhem, home to the Accoya® processing plant.

That afternoon we spent our time in the ‘classroom’, and on the factory floor, learning about the impressive process of acetylation, and the science and technology behind what they do, and why they do it. There is a big focus on sustainability and environmental responsibility by the team at Accsys technologies who are extremely passionate about, and protective of, the unique non-toxic modification process that transforms New Zealand grown Radiata pine into one of the most durable and stable timbers available.

Accsys technologies are the largest buyer of sawn clears Radiata Pine out of New Zealand and they produce a massive amount of processed Accoya® for Europe, the UK, and other parts of the world. Only a tiny proportion of the Accoya® timber comes back to New Zealand and thus, a great export story for the New Zealand forest industry.

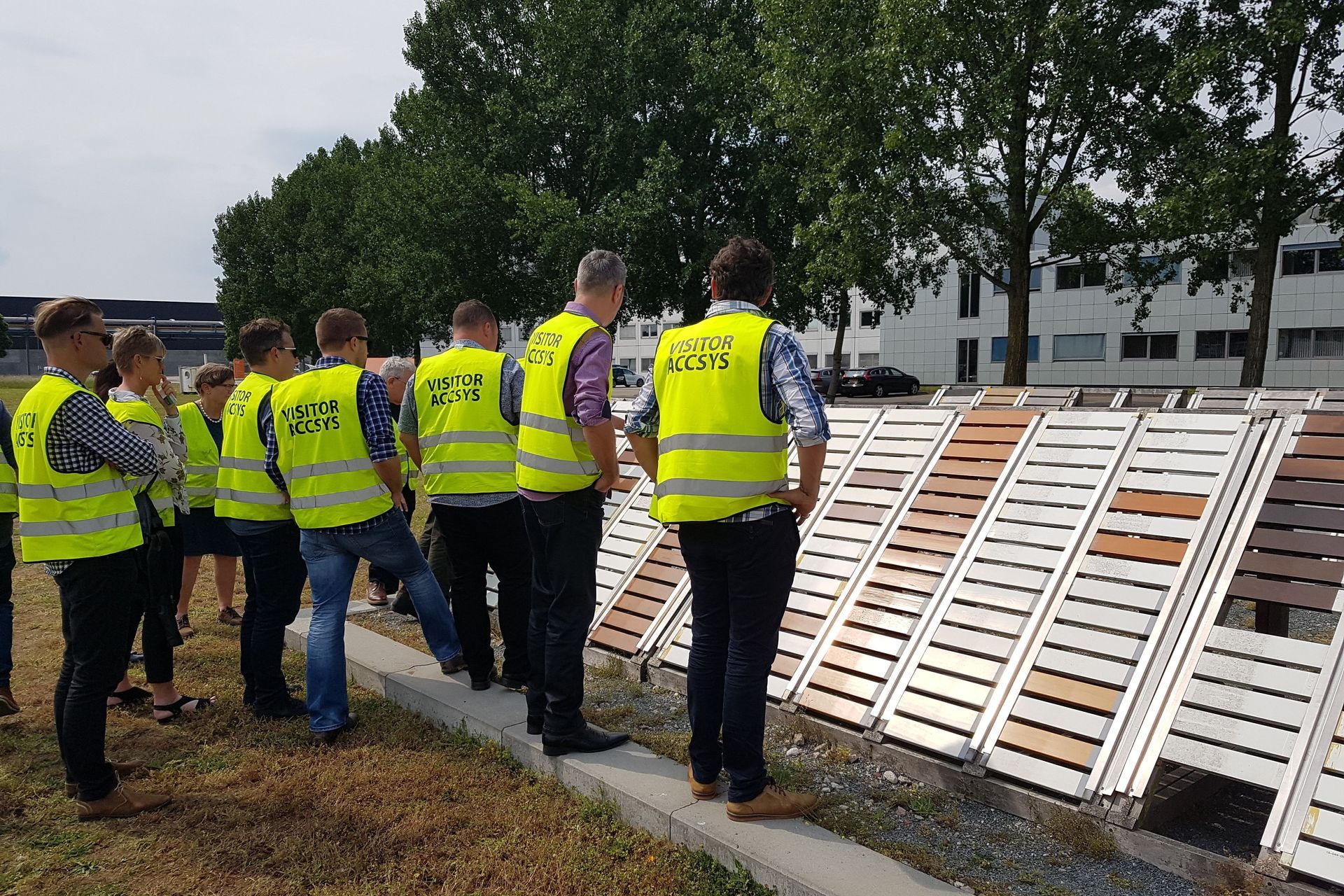

The morning of day four, we spent viewing and analysing the durability and coating testing facility at the Accoya® plant, before we headed off to Venlo, a city on the Dutch/German border. Here, the Venlo City Hall, the new city administrative building is one of the world’s leading examples of a cradle to cradle inspired building. The design brief here was set not only to reduce impact on the environment but to be beneficial to it. This building generates its own electricity through solar panels, naturally filters and cleans the air, re-uses rain and grey water, and reduces energy consumption by creating a natural ventilation system throughout. They have incorporated natural timber and carefully selected materials and products that contain no harmful chemicals or compounds especially when considering such things as foam in seating or carpets and wall coverings. Altogether, a stunning example of what can be achieved when, innovative design, along with willing clients use sustainable products and materials to produce one of the healthiest working environments on the globe.

We departed Venlo and after a quick detour across the border into Germany (for the benefit of those who had never been there), we headed south to Zeeland and the delightful medieval town of Bergen Op Zoom, where we checked into to the 622 year old Hotel De Draak (The Dragon Hotel).

Although the next day weather was slightly inclement, we spent the time viewing some outstanding Accoya® structures around the region where, numerous historic forts, castles and battle sites have been revamped and opened to the public. Among them, the famous Moses Bridge and Pompejus Tower at the strategically important Fort De Roovere are outstanding examples of using a versatile and durable non-toxic timber to great effect.

The floating Accoya Ravelijn bridge was also a highlight (although a little dicey in the rain). Later, Fred, our dedicated and unflappable driver, took us on a detour out to the fringes of the country where we viewed the massive dykes and lock system restraining the North Sea from inundating the lowland regions. The Dutch it seems are already prepared for the inevitable sea-level rise we are seeing from global warming.

Our last full day began viewing a few Accoya clad buildings in and around Rotterdam and The Hague, before lunch at the up-market, and very sought after Breakers Beach Café, at Noordwijk. This is an Accoya clad building, situated on the large beachfront sand dunes that are a feature of this part of the coastline, and fully exposed to the often harsh and unforgiving North Sea, and all that it can throw at it. Here, Accoya perfectly demonstrates its unrivalled durability, stability and long lasting nature.

The final evening we spent back in Amsterdam, after virtually circumnavigating the country, it was the time to reflect on a fun week where the group got to see some amazing structures, unique countryside, and taste some awesome food, as well as forming some great new friendships.

We trust the trip helped to gain some understanding and insights into the theory behind acetylated timber and its many uses, and hope it will stand as an inspiration to some new projects back on home soil.

A massive thank you to Laurens Notenboom and the team at Accsys Technologies for making this trip such a success. We appreciate the time and effort that goes in to planning an organizing such an event. Looking forward to next year's tour!