Ambro Metals Ltd: A guide to exterior architectural excellence

Written by

03 May 2022

•

5 min read

The world of architectural and industrial non-ferrous metals can be complex, and often requires some educated guidance — for everyone from architects and specifiers to homeowners.

For this and a host of other reasons, it’s imperative that these stakeholders receive the right advice from the right people in the early stages on design and selection. People with a wealth of experience, who fundamentally understand the various metals' performance, along with a proven track record of delivering outstanding results with bespoke exterior options.

Ambro Metals has carved their way into this valuable role. Established over four decades ago in Avondale, the company offers long-term, quality architectural metal solutions, and offers customers a comprehensive range of stock and supply options to meet their requirements.

ArchiPro sat down with Ambro Metals’ Adrian Ward and Stephen Davies, who talk about how the companies approach in giving advice to clients, the part Ambro plays in the larger architectural landscape, and how it navigated a challenging project in North Piha.

As a supplier of architectural and industrial non-ferrous metals, how do you approach giving advice to clients? What kind of considerations do they need to think about?

Adrian:

It’s important before we can give advice we find out as much as possible about the client’s vision and nature of the potential project.

We ask several questions: Is the project commercial or residential? What type of environmental location, and the profile they’ve interested in? Had they seen any specific project reference from our portfolio that prompted them to come to us in the first place? The answers to these questions help us to orientate and put forward suitable options.

From that point, we can then qualify correctly what we put forward to the client from our range of products that we know will work based on the collected information. This ensures that the presented products are fit for purpose and are compatible with other construction materials, and will work for the proposed fabrication and installation demands.

We can also respond with examples from our portfolio that might reflect similar to their inquiry.

Our focus is to create a positive experience with unmatched results generating repeat enquiry by the architect, installer and all other involved parties. We strive to enhance the look of New Zealand’s exterior and interior architectural projects. We believe that the direction we are going is starting to deliver projects recognisable at international levels.

How does Ambro Metals fit into the larger architectural landscape?

Stephen:

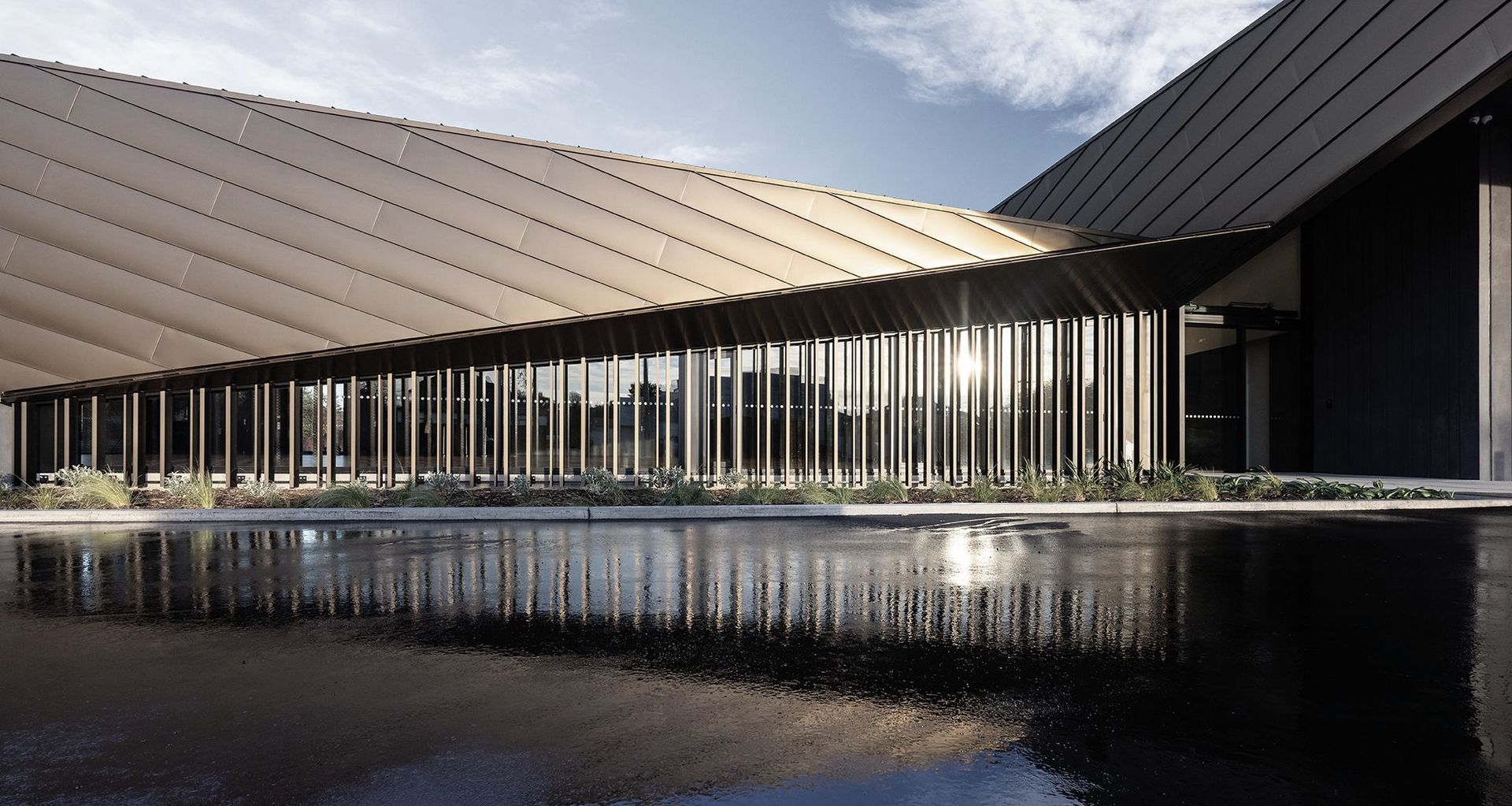

The company has been heavily ingrained in the architectural project scene for quite some time now. We’ve been involved with some of the most prestigious roofing and cladding projects around New Zealand — from the Auckland War Memorial Museum to Te Manawa Library including many award winning residential homes.

What we’ve done since then is evolve our boutique product range to cater to a much wider scope of architecture applications.

We have built a strong foundation in everything to do with the exterior in terms of performance, longevity, sustainability, colour and budget. But now, and more excitingly, we are advancing on the capabilities of architectural metals, and expanding on our range to offer more attractive surfaces for internal applications.

This is a great indication of how Ambro Metals is stepping up and providing more bespoke and tailor-made solutions for all architectural disciplines.

Adrian:

We have created a strong relationship built on trust with numerous installers who rely on our knowledge as we do with them to put a design concept into reality for the specifier and client. When you bring a network like this together early the results speak for themselves. We are invested in our specifications through the process.

So that's how we're altering the landscape — we're making desires become reality, offering high-performance products through a network of people that understand how to work with these products — and who understand the technical capabilities in order to provide the right details.

Can you tell me about the North Piha project - what was the brief, were there any challenges, what was Ambro's involvement?

Stephen:

The brief for this project originally came to us as a reclad. There was an issue with the original substrate installed for the roof and wall cladding, which was zinc.

The project, situated on the notorious West Coast, is well known for its aggressive and harsh environmental conditions. This created complications for the original exterior's corrosive strength along with material compatibility.

Adrian:

Above all our job was to make it more durable and to fit back into the environment without noticeable change. We selected to present a finish from our range of EURAMAX pre-coated aluminium, which delivers a superior paint system with flexibility for folding and curving, resulting in enormous architectural panel versatility and unmatched durability.

With the installers we presented this idea to the architects — and they loved it, it ticked every box. Compared to zinc, it’s specifically designed to handle this harsh unique coastal environment.

Contact Ambro and have a conversation about how they can support your project.