Cedar cladding: it’s all in the detail

Written by

06 March 2019

•

5 min read

New Zealand’s climatic conditions can be extremely harsh on buildings so it is crucial that architects and designers get the creative details of a timber façade just right to ensure cladding will endure the ravages of time and also look amazing.

Cedar has proven itself to be a reliable and popular choice as a building material for cladding in New Zealand. “Cedar is popular as you can do almost anything with it,” says Ray Hutton of Rosenfeld Kidson, suppliers of cedar, larch and other specialist timbers. “Its inherent stability gives architects and designers greater creative license to achieve the designs they’re after.”

“As a log, cedar is sustainably harvested, it dries quickly and machines profiles easily too,” explains Ray. “It’s the ultimate commercially-supplied softwood for exterior façades but the key benefit is that it gives us creative license to create many different profiles: to be able to add texture, depth and seamless transitions to the façade – to be very creative for the specifier, as it were.”

In keeping with the current Kiwi design trend for ‘rustic modern’ or ‘contemporary rural’ style homes, popularity has grown for horizontal shiplap or ‘rusticated’ timber weatherboards as a cladding. But it is the junction details that are crucial to get right, suggests Ray.

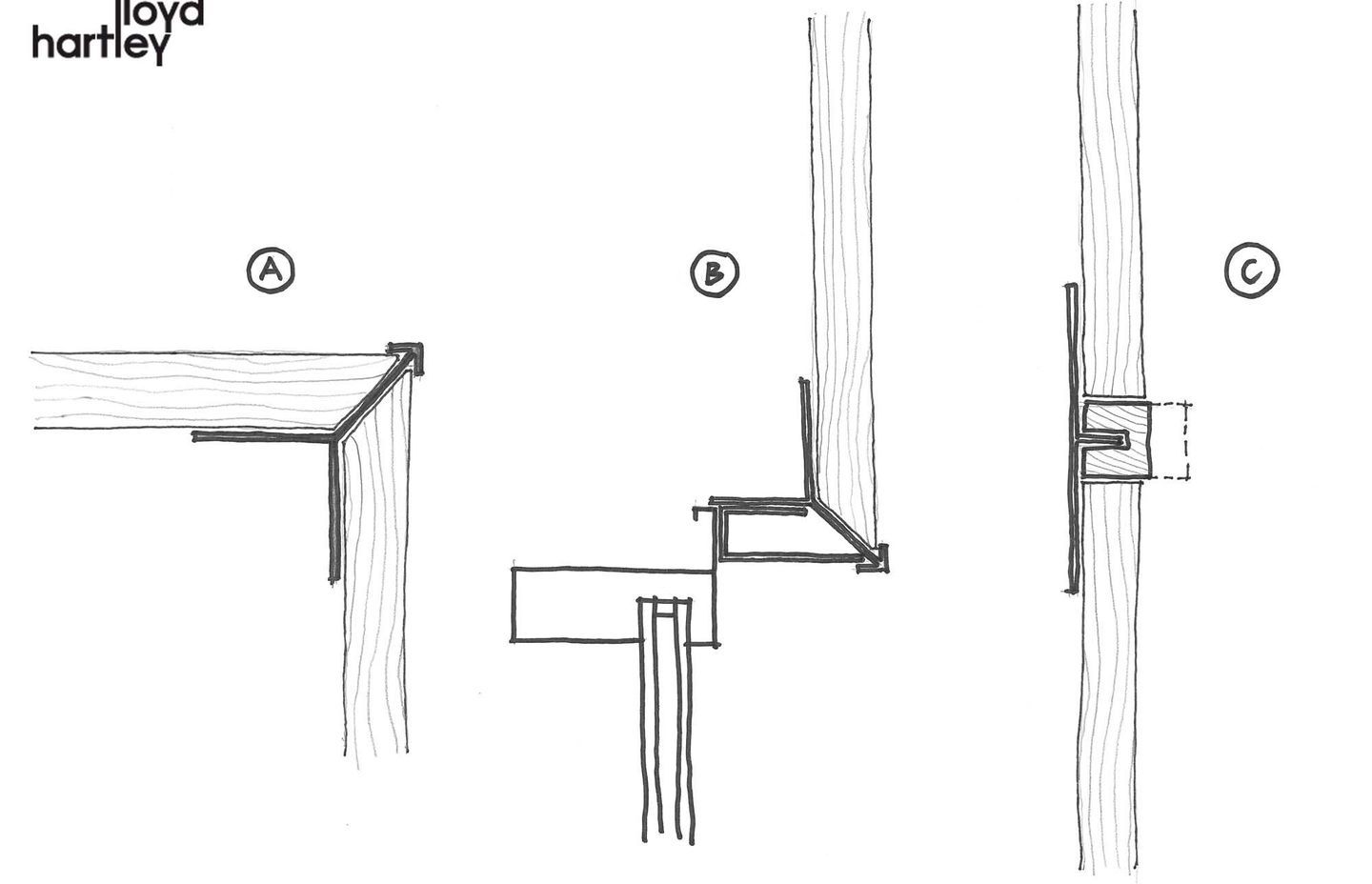

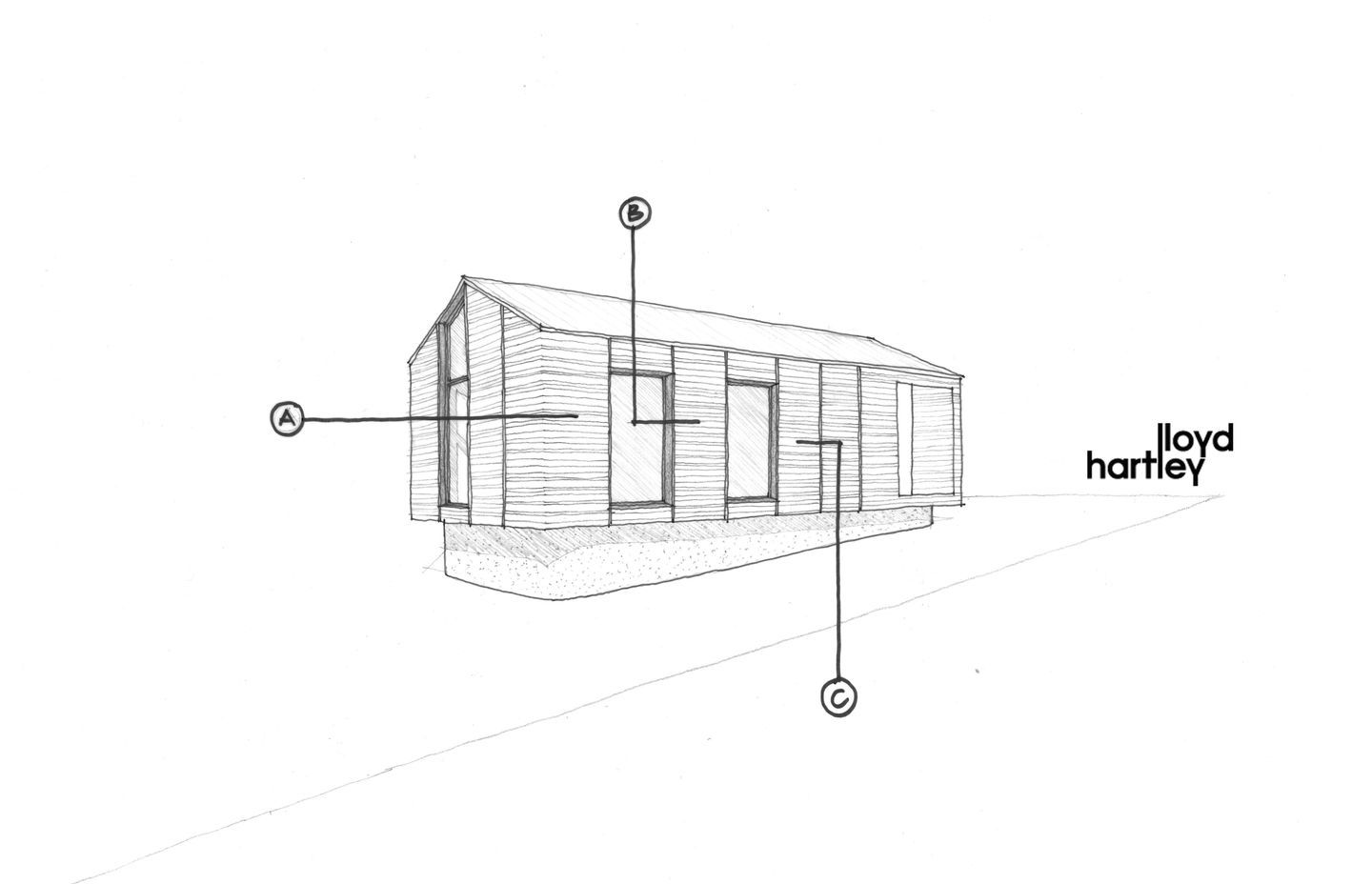

“Recently, a client of ours designed a house that’s clad in modern rusticated weatherboard – running horizontal – and the detail they wanted was for the corners to be mitred and the horizontal line to be seamless from point to point. Linked to that, he also wanted to add relief to the façade by dragging the windows back to create recessed windows.”

Rosenfeld Kidson was able to provide a solution that achieved the desired look in a cost effective way, while also ensuring long-term, weathertight performance.

Ensuring these architectural details are perfect is something the team at Rosenfeld Kidson prides themselves on. “Linking into the ‘modern rusticated’ trend, one of the systems we designed many years ago was random-width cedar, where the boards are different widths, but people wanted to stagger that aesthetic in depth also and have the flexibility to make them thicker and thinner in either a horizontal or vertical line. So we created a vertical flashing detail that allows vertical boards to be run off horizontal weatherboards and vice versa.”

Ray explains: “Daniel Marshall Architects created some of the very first modernist Kiwi bachs and this was one of the first uses of vertical cedar where the façade was flush with the joinery, creating clean, crisp vertical and horizontal lines, which are now the quintessential Kiwi bach! This can be seen in the Lloyd Hartley sketches (above and below). The detail shows the transition from weatherboard to weatherboard in a vertical line.”

One of the main reasons that Rosenfeld Kidson has been able to work with specifiers on creating innovative solutions for architectural details is because it has invested heavily in modern machining methods.

“We have some of the best machinists and manufacturing capabilities in the country, which helps us to push creative boundaries,” explains Ray. “A key focus of our business is ‘design intent’ – to give the specifier what they want, hopefully before they even know they want it because we’re investing in research.”

The firm has been refreshing its company profile, including releasing a full set of new construction details. “We’ve just updated all of our Cedarscreen systems and these include new innovative details, such as the modern mitred-corner details for rusticated weatherboards, recessed windows and the interchangeable vertical junction,” Ray says. “We can also offer these in other timber cladding alternatives, such as Truwood® and European Larch.”

In recent years, Truwood has proven to be a very popular cladding material as it is a cost-effective alternative to cedar, with similar characteristics. “It’s a beautiful, homogenous, low-density hardwood that we have treated in Europe and manufactured in New Zealand to comply with our Building Code requirements,” explains Ray. “It’s available for use with all Cedarscreen systems and it has great dimensional stability, durability, colour and grain structure.”

Cedar is Rosenfeld Kidson’s core offering but it also imports many other speciality timbers. This range of sustainable hardwoods and softwoods offer many alternatives for different end uses.

Many of these timbers can be used in exterior as well as interior applications. Rosenfeld Kidson can match interior product profiles to the exterior weatherboards, creating seamless transitions for inside-out design schemes.

However, with a variety of timber species and tones now being used within one house design, homeowners and architects can be challenged to match the different timber tones.

In many instances different timbers are used and, according to Ray, “When choosing interiors, it’s about blending the timbers. Oils are drawn into the timber, rather than sitting on the surface, so you can rag on a dark colour and rag it off to make it more honey-like or add a white wash to make it pale, or a black tone to minimise redness and make it more of a neutralised brown. But, more often than not, the oils add an even lustre and depth to the timber to give you the right result.”

Ray suggests that homeowners link up with specialist people who can provide good advice. “I’m a big fan of the Dryden WoodOil products for exterior cladding because you can manipulate the colour on the timber to actually give you the tones you want and it is fantastic for the wood itself."

If you’re looking for advice about timber cladding, you can contact Rosenfeld Kidson on ArchiPro here.