The changing standards of high-end porcelain and stone flooring

Written by

16 February 2022

•

4 min read

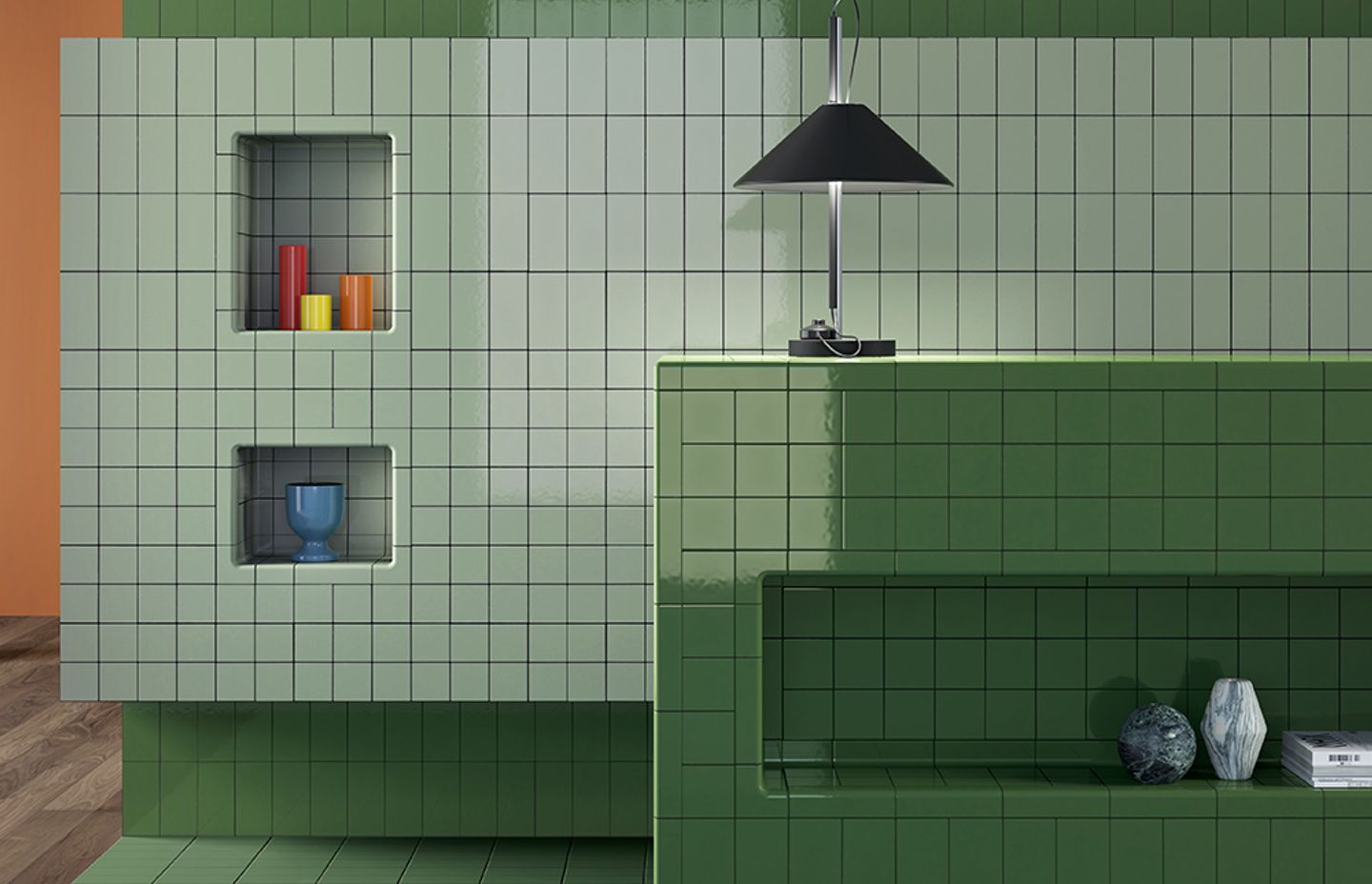

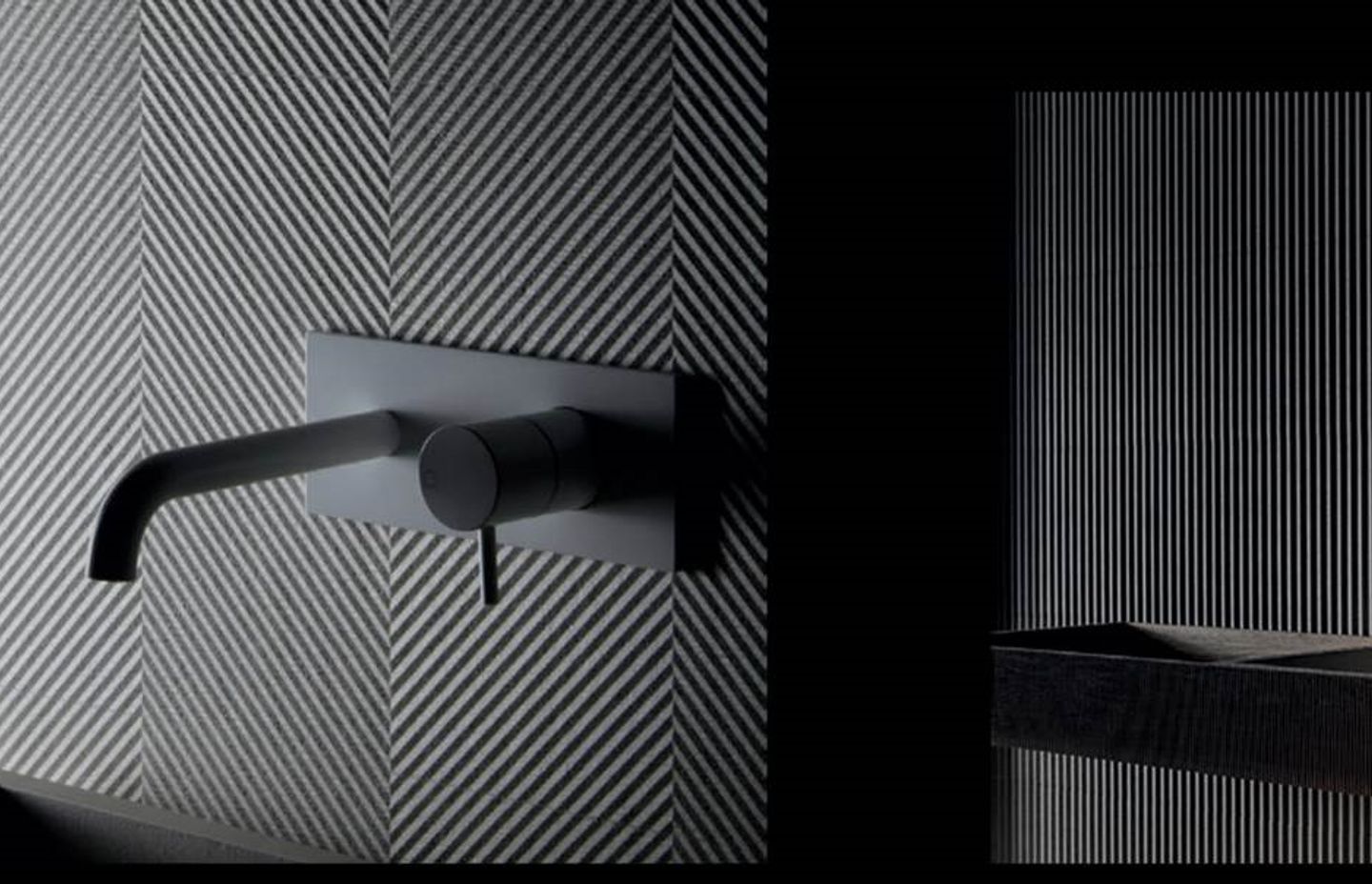

There has been a shift away from the minimalism trend of the last decade. Where once whites and other neutrals reigned supreme on walls, floors, furnishings and decor, now more colour and overstated decor is appearing throughout homes, businesses and commercial spaces.

It’s a trend seen in almost every industry in the building and architecture sphere: coloured tiles in bathrooms; vibrant furnishings and fittings; eclectic patterns and materials adorning walls and ceilings.

The work of European Ceramics, a tile and stone importer that’s been a leader in the New Zealand market for over 30 years, is clear evidence of this trend. Focusing on high density commercial spaces and upmarket residential projects, the company has seen firsthand the change in the last few years.

“In the past, big commercial projects would just use standard basalt flooring and white tiles in the bathrooms,” says Jason McGranaghan, Managing Director of European Ceramics. “It’s totally changed now — people are spending a lot more money now on fit-outs, upgrading to Italian material, and putting a lot more detail into specifications.”

The trend in stone flooring is veering towards luxury

Having been at the company for almost two decades, Jason has seen European Ceramics work on various high-profile New Zealand projects over the years: the ANZ building in Auckland’s CBD; the Sofitel Hotel on the city’s waterfront; shopping malls and university buildings and more. Seeing the progression of styles and stones throughout these buildings as they have been fitted out over the years is proof, Jason says, of the change in appetite — and budget.

“People are up-speccing their homes, finding more luxury, lifting their specifications — and this has bled into the commercial market,” he says. “These spaces have an impact on people’s emotion, and increasingly they want to feel as comfortable in their office or mall environment as in their home.”

This is the case in several of the company’s most recent projects. Two buildings on Fanshawe Street in Auckland’s CBD saw an order of very large commercial floor plates, with natural stone and porcelain materiality — chosen as a statement of beauty and solidity as well as to pass slip requirements.

Meanwhile, European Ceramics has recently finished a spate of shopping mall fit-outs: Sylvia Park in Auckland, where the company will continue to work into the future, as well as the Tauranga Crossing mall. Work on the Invercargill shopping mall is due to begin soon.

Sanet Share, the Senior Sales Representative for European Ceramics, says the company’s involvement on residential projects, like apartment buildings and retirement villages, is also a key part of its business.

“We work with Peter Jones, a very well known developer in Auckland. We've done all his luxury, high-end residential units from Mission Bay to St Heliers,” she says. “We’ve also been involved in hotels in the Pacific Islands, like Fiji and Rarotonga — so there’s lots going on.”

Sustainability in action

With so many business enquiries and large projects requiring large volumes of stone tiling, naturally the sustainability of the business and its suppliers comes into question. But Jason says that the use of natural stone is a sustainable practice in itself.

“Natural stone has a huge longevity,” says Jason. “Overall its carbon footprint is a lot lower than even bench tops of resin or vinyl floors or even timber floors. There’s no petroleum byproducts in the manufacturing process either.”

He also mentions its reusability: natural stone can be repurposed time and again.

“One of the best things about it is even if you pull it up after an average of 50-80 years, it can be recycled and reused.”

This sustainability carries over to European Ceramics’ partnership with Florim. Florim is an Italian brand that is a leader in industrial ceramics — and also in their sustainability practises, not least in the fact that they use solar panelling to procure 85% of their power.

“They recycle 99.9% of their water,” says Jason. “They bag every item of dust that comes out of the place. And they've obtained a new standard now, which is called B Corp.”

Companies that attain the B Corp certification must adhere to a high social and environmental standard, must make themselves accountable to all stakeholders, and exhibit transparency by allowing their performance to be measured against B Labs’ own standards.

Surrounding yourself with a company certified with this certification, Jason says, means that European Ceramics’ own sustainability standards are raised — benefitting not only the company and its employees, but also its clients and customers.

Learn more about European Ceramics.