Choosing the perfect polished concrete floor finish for your space

Written by

25 May 2025

•

5 min read

Polished concrete is an extremely versatile solution for many flooring applications, one that is becoming increasingly popular across Australia. Arguably, the most important decision to make when it comes to polished concrete is the type of finish to go with.

We spoke with Michael Comben from Husqvarna Construction, who began his career as an installer, for his advice on how to choose the perfect polished concrete floor finish for your home or business.

Start with intent and application in mind

The first thing to think about when it comes to polished concrete finishes is the intended use of the space. Different types of finishes fundamentally exist for not only different aesthetic properties but also different applications, so thinking about this in depth and detail is the first step to set you up for success.

Michael describes the importance of this on both a functional and aesthetic basis.

“We can install polished concrete floors in many different environments, but part of the decision really comes down to what the space is going to be used for. Is it going to be used for a warehouse where forklifts will be running over the top of it, or is it for a home with an aesthetic designer style?”

The intended use of the space may also steer you in a particular direction due to compliance and regulation, especially in the commercial space, as Michael continues.

“In a commercial environment, you need to comply with slip rating, which can vary depending on a variety of factors. A higher gloss finish reduces your slip resistance, so in some situations, a high gloss finish can not be achieved, because you won't achieve the required slip resistance.”

Understand the options and differences

Once you have thought about your space and the general demands of it, learning about the different types of polished concrete finishes will help you understand the options and how they can meet your needs.

Michael broadly describes how polished concrete finishes differ from one another, and the impact this has on their look and performance.

“Different polished concrete finishes have slightly different properties depending on how much stone exposure you have. By exposing the stone and grinding off the top layer, we're actually building a stronger and more durable floor. From there, you choose what sort of gloss level you wish to achieve.”

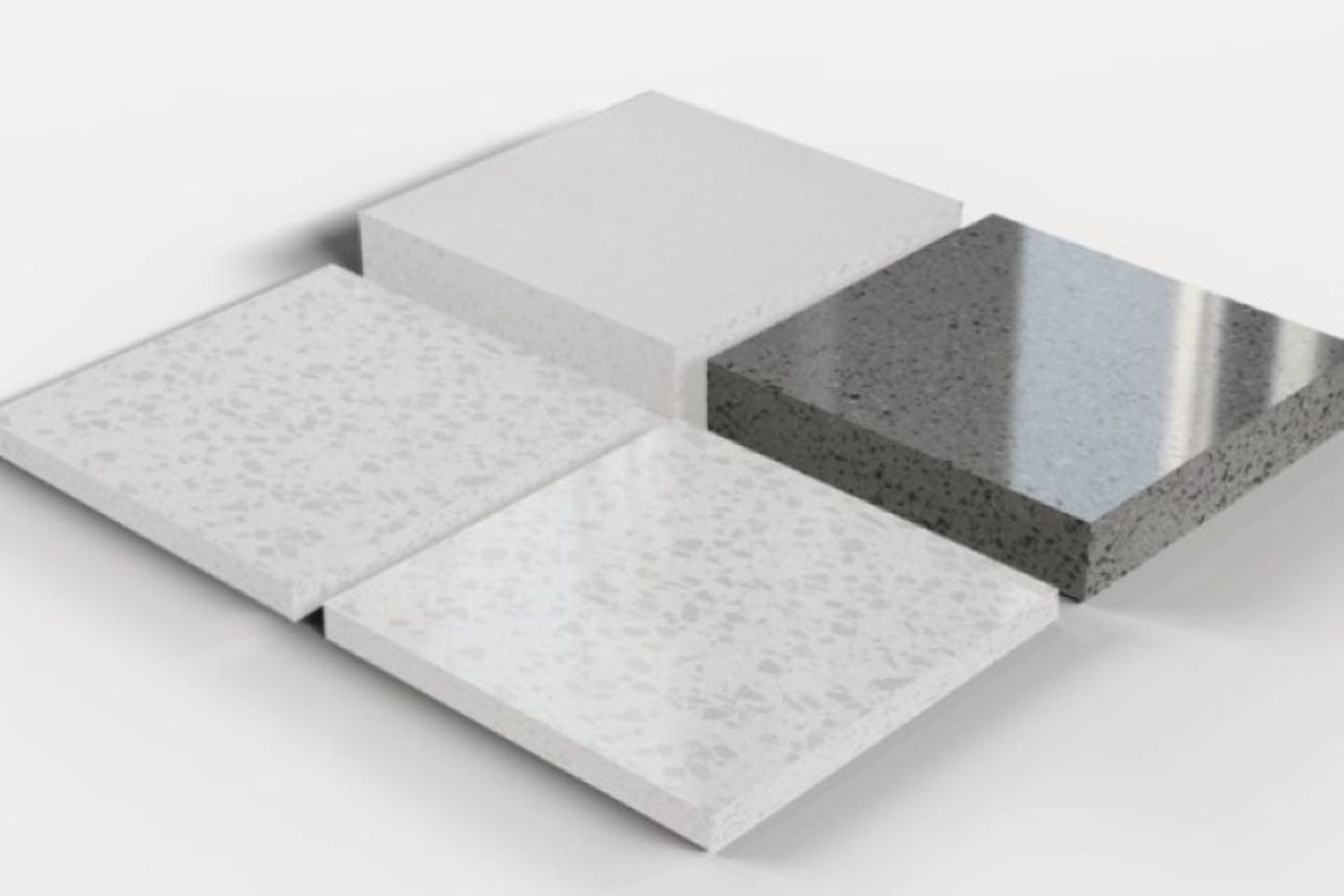

Husqvarna Construction offers four predetermined polished concrete floor finishes, which are briefly described below:

Husqvarna Superfloor™ Silver: A matte concrete floor with a high level of aggregate exposure.

Husqvarna Superfloor™ Satin: A medium gloss concrete floor with a low to medium level of aggregate exposure.

Husqvarna Superfloor™ Gold: A highly polished concrete floor with a low to medium level of aggregate exposure.

Husqvarna Superfloor™ Platinum: A highly polished concrete floor with a high level of aggregate exposure.

However, as Michael explains, there is also the opportunity to create a custom polished concrete finish, should these not quite meet your requirements.

“These predetermined options probably cover 80% of projects, but we can also create a custom specification which helps us cater to other environments, for different needs and aesthetic properties. We can choose the level of stone exposure and have varying gloss levels too.”

If you’re laying a new concrete slab, there’s also the opportunity to infuse a bit of colour through the choice of concrete mix.

“You've got the ability with certain companies to choose the concrete colour you want through decorative mixes. We can then come in and achieve the desired level of stone exposure.”

Finding the right professional

One of the biggest determining factors for achieving the desired finish you want lies in the skills of the professionals involved. Strangely, this is sometimes overlooked as people focus their attention on the product, but as Michael describes, the ability and craftsmanship of the tradespeople on the job are key.

“Polished concrete really is an art form, so making sure that you engage a reputable contractor is critical. We have our accredited contractor program to make sure that we have high-quality contractors that are delivering high-quality products and finishes for our clients.”

Programmes like this have resulted in improved, polished concrete floor finishes across the board, something that Michael has witnessed himself over the years.

“The technology is improving all the time, and the skillset of contractors is getting better and better. There are new tools now getting used for finishing, edgework, stairs, and the more intricate details, making it easier for the contractor to install at a higher level.”

Quelling misconceptions and the long-term view

In wrapping up our discussion with Michael, we asked about any misconceptions about polished concrete floors that often cause doubt in people considering their options.

“People think polished concrete is cold, but it has a lot more thermal mass than a tiled floor, for instance, it will hold residual temperatures very similar to room temperature. You can open the blinds and have the sun on the polished concrete, and the heat will radiate out through the entire slab. In contrast, tiles are individual pieces restricted by grout.”

Michael also continued to say that the return on investment over the long term makes polished concrete floors an extremely cost-effective solution.

“Polished concrete floors can have a relatively high initial cost of installation compared to some other floor systems, but over the life cycle, when maintained properly, you can have a floor that looks as great as it did 20 years after it was installed. So the actual cost of ownership of a polished concrete floor over its life cycle becomes very cheap.”