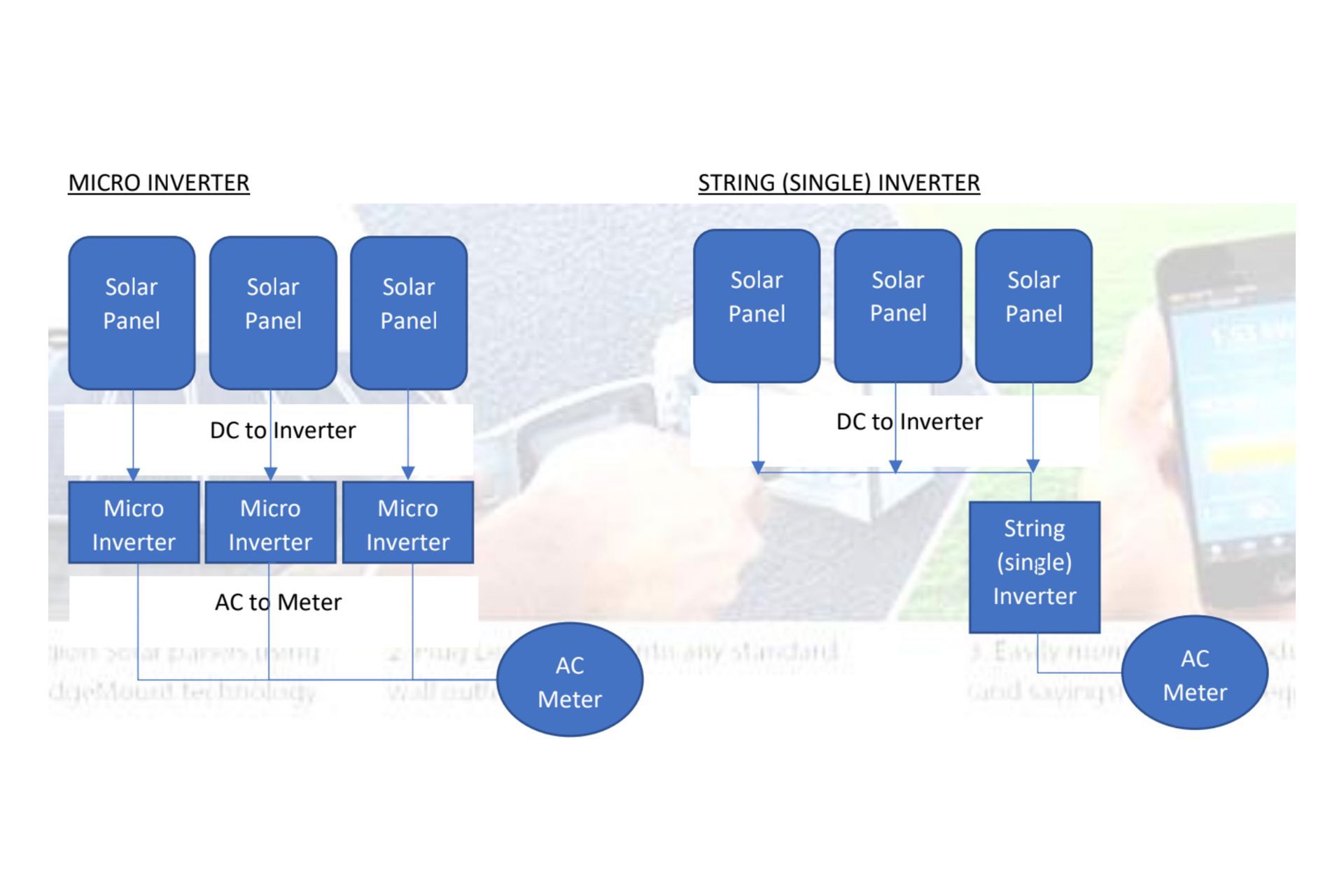

Comparing String Inverters & Micro Inverters

The string inverter accepts DC power from a “string” of many solar panels wired to a large single inverter. The micro inverter is a small inverter that converts power from a single solar panel. So, in the string approach, there is a single large inverter producing the AC power for all of the solar panels. In the micro approach, there is small inverter for every panel on the roof.

If you are interested in installing a solar power facility on your roof, you will request quotes from two or more local solar contractors. You rely on them to suggest the best approach for your needs. Most often, the contractor will suggest the string inverter approach.

Why is this true? In the first place, that is the way it has always been done. The micro inverter in a newer and more elegant technology while the string is the more traditional approach. In the second place, the string inverter offers a slightly lower initial cost (between 3%-5%). If you include the added installation cost and the peripheral hardware for the string, the total cost difference becomes minimal.

Solar companies quote against each other using a cost per watt amount. Companies using the micro-inverter approach will come in with a slightly higher estimate and probably lose your business as a result. So, the cheapest path for them is to quote the string inverter.

Advantages of the Micro Inverter Approach

Except for minor differences in the initial cost, the micro inverter offers advantages in almost every measurable parameter and under every operating condition:

Power Production:

The micro inverter installation will provide more power from the same number of panels. The string inverter is analogous to a stagecoach race. The stagecoach (string inverter) is pulled by 10 horses (solar panels). The stagecoach will go only as fast as the slowest horse in the string. This means that the string inverter will produce power at the rate of the least efficient solar panel in the string. This is caused by minor variations from panel to panel. Those variations can make as much as 5% difference between the most and least efficient panels in the string. The differences actually increase with the age of the system. Even an accumulation of dirt or leaves, even shading, on a single panel will adversely affect the power production of the entire string.

The micro inverter approach is quite different. Each solar panel is served by its own micro inverter. That micro inverter produces the maximum total power available from that panel, regardless of its age or condition. So, all panels in the array are producing power at their maximum output.

The solar panel power generator has a life of 25 years or longer. Imagine the benefit and better return on investment of a solar array that produces >5% more power over its lifetime. This is important and the additional power produced over the lifetime of the system can be substantial.

There is an additional benefit as well. There are many operating conditions that will slow your string inverter power production to a crawl. If there is a shade condition that affects one or more panels in the string, it will affect all of them equally. For example, there may be a shade tree close to the roof or a chimney that obstructs a single panel for some period of time. What about partly cloudy days where power is interrupted or reduced while that cloud passes over? These main are minor and short term interruptions taken individually. The difference in total power produced over the lifetime of 25 years can be quite significant.

Installation Costs:

The micro inverter system is usually simpler to install. One of the most common problems your contractor experiences is putting a large system together only to find that it does not work properly. The string inverter does not monitor each panel individually, only the sum of their power. So, if there was some problem or error during installation, finding the fault can be nightmarish. In the micro-inverter, each solar panel is monitored separately. In that way, specific faults are quickly identified and corrected.

Command and Control:

The string inverter monitors and measures only the total power produced by the string. In the micro inverter approach, each panel is monitored and controlled separately. One can look at the micro system and immediately identify and particular panel or inverter that is not operating properly.

Reliability and Service:

It is important to know that these solar power generating systems are wonderfully reliable. The different components are designed for 15-25 years of use and they have a good field reliability track record. No matter how reliable they are, a service call is on the horizon sometime in the future. Any large system such as these will suffer a failure of some component at some point.

Here the micro inverter approach offers an advantage as well. Electrical engineers always try to design any system so that a single failure will not bring whole system down. The string inverter architecture is inherently vulnerable to system failure in the event of a single fault. If any part of the system fails, the whole system will crash. Its architecture is nothing but single fault points. So, if any panel, inverter, wire harness or connector fails, the system stops producing energy. Even a loose wire can do it.

The service call can be time consuming and expensive. The string inverter monitors only the sum of the power produced. It does not look at each solar panel. So, the service people must first find where the fault exists by getting on the roof and testing each panel until they find the fault. That can entail disassembly of the whole rooftop system.

The micro inverter eliminates that effort. If a single panel fails for some reason, the remainder of the system continues to deliver power. So, you have a minor reduction in system output instead of a system collapse.

Diagnosing where the fault lies is simple as well. Each solar panel is individually monitored. In the event of a failure, the service person will know exactly where to go to fix the problem.

System Scalability:

There are many reasons to “tweak” the system after it is installed. The ideal system is sized so that you are running the power meter slightly backwards during the colder months and slightly forward during the warmer months. Any other result means that you purchased too large or too small a system. Some users prefer to start with a small system and continue to grow it as they can afford to do so. Other users may find that the initial system was too small to have the desired effect and wish to add 2-3 more KVA. The string inverter approach does not easily lend itself to additions to the power array. If the string is already operating at full potential, it must be replaced with a larger or a second string inverter. The micro inverter approach is perfectly suited to scaling. Each panel is served by its own inverter and they are added to the system in sets; one panel and one micro inverter. So, one can easily add as little as 200 watts or as much as 10 KVA to the existing system with relative ease and simplicity.

The micro inverter is the newest technology used in solar power production systems today. It was developed to improve on the performance delivered by the older string inverter approach. The micro inverter will deliver more power under all conditions but excels when conditions are less than ideal. There are many other advantages as well as discussed above. It is clear that the industry is moving toward the newer micro inverter approach. Even the established leaders in string inverters are moving quickly to add the micro inverter to its inventory of solutions. The string inverter is not yet a “fossil” but can best be described as an “OK” solution that is quickly being overcome by the advancing technology.