Creative Shapes in Lighting

Written by

22 October 2020

•

4 min read

Necessity is the mother of invention—or so the saying goes. That was certainly the case for Bright Light designers when a Dubai client specified a sculptural, eight-metre light installation for their commercial interior project.

Shipping a light installation on a grand scale has the potential for disaster and it is something lighting designers are only too familiar with; broken joins in transit are a common casualty. So Bright Light set out to tackle this familiar issue and in so doing, created a whole new class of lighting product—one that is customisable and adaptable to a client’s needs.

The new lighting innovation came about when Bright Light director, David Powley, challenged his engineers to design a large-scale pendant in a format that could be installed without patchy joins or potential for breakage.

“The risk of damage due to welding on soft aluminium is fraught. Our engineers designed a joining system so that lights could click together like Lego.”

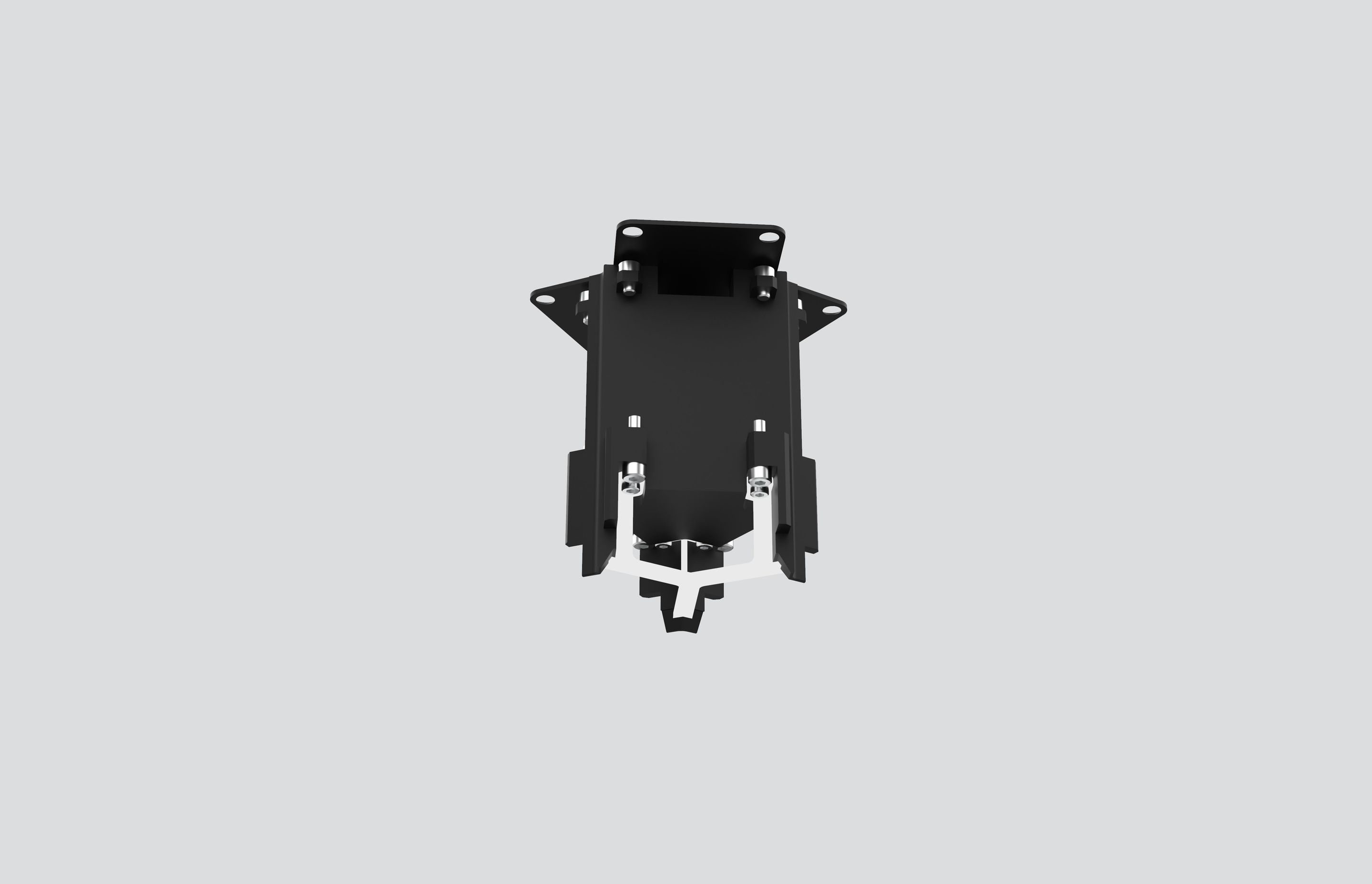

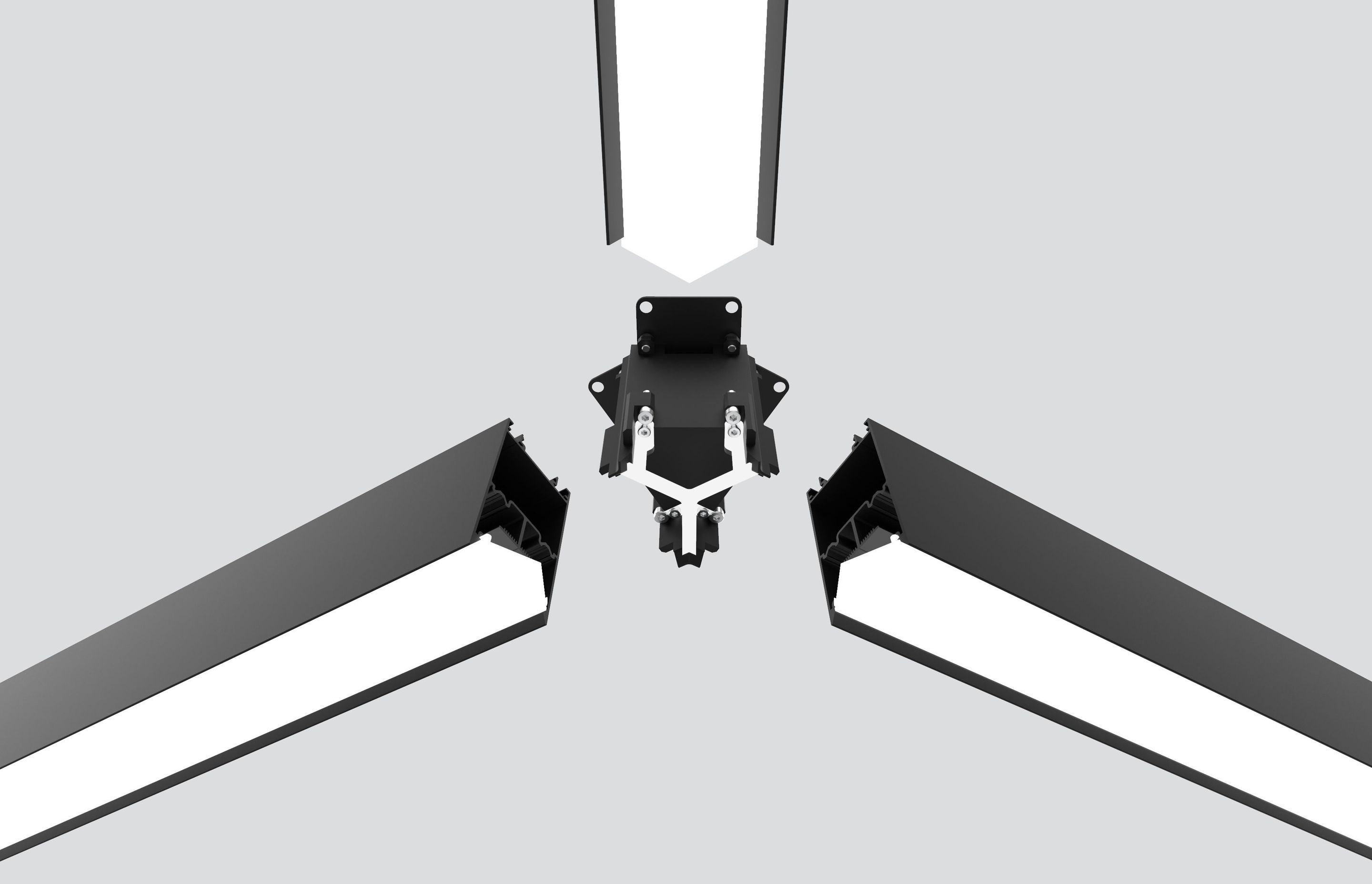

What the engineers came up with was remarkably adaptable: a joiner, which their Highline 05 100mm luminaire product could slot into like pieces of Meccano. It means that lighting installations can be as large or as small as the client wishes, meaning the possibilities of lighting configurations and shapes are endless.

For the Dubai project, the new joiners meant no breakages in transit, because the 800mm lengths of Highline 05 luminaire slot easily into the joiners, on site. The resulting hexagonal lighting arrangement creates a showstopping sculptural piece. Suspended in a high-end office environment it not only provides a focal point in the room, but it delivers the light needed in the busy working environment.

The joiners are particularly suited to commercial spaces such as art galleries, entrance foyers, or boardrooms, but equally can provide a bespoke showstopping feature in commercial spaces with interesting layouts.

The joiners are made in a variety of angles, to enable multiple possibilities.

“It allows designers to use it as a tool set—they don’t have to come up with the shape themselves. They can play with the joiners to lead them to a particular configuration and the customer can make onsite changes if they want to.”

There are three-way joiners and a variety of different angle joiners, allowing a vast amount of flexibility. Currently Bright Light is working on a range of new joiners including T-junctions and are open to discussing custom joiners for clients.

The joiners come in standard finishes of silver anodised and black or white powder-coated and can also be powder-coated in any colour to suit a given specification.

The Highline 05 100mm luminaires, which are the lighting product the joiners are designed to fit, equally have a range of options to suit any instalment. They can be suspended, surface- or wall-mounted and come in warm white, natural white or cool white.

David says this vast range of options means applications are endless. Equally, they can be tuneable or RGB, which is useful when used as an up-light. Additionally, they are compatible with all modern-day control systems.

Given the current global climate, where the supply chain can be a tricky thing to navigate for architects and designers specifying lighting, this lighting system has a distinct advantage.

“The product is made in New Zealand, so it is ready to go and can be supplied to any specification within weeks. Even the largest installations can be shipped across the world in their unassembled form and easily slotted together on site.”

Essentially, they’re the most creative and versatile lighting system around, says David.

“They allow designers and specifiers to play with lighting and explore different options, simply through playing with the joiners. The possibilities and applications are endless, and the product provides a creative starting point for exploration in lighting design.”