Designing for Longevity: Auto Mossa's Commitment to Sustainability

Written by

17 February 2025

•

5 min read

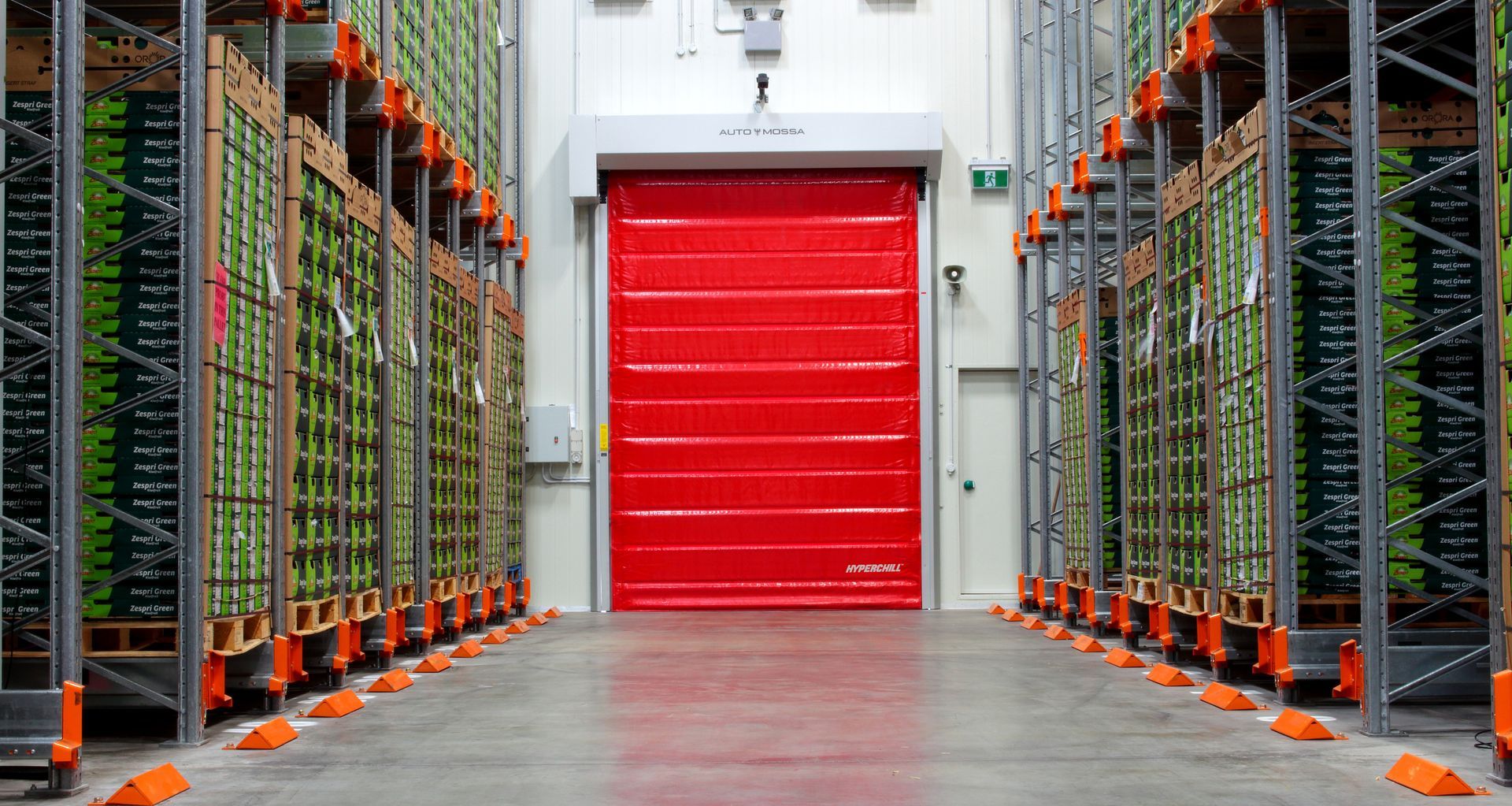

Specialising in rapid doors, Auto Mossa is committed to engineering solutions that not only optimise efficiency but are built to last.

Designing for longevity also stands as more than just a design principle in their products—it’s a commitment to engineering products built to last. By prioritising durability, high-quality materials, local manufacturing and continuous innovation, Auto Mossa ensures that each rapid door performs at its best while reducing maintenance needs and minimising environmental impact.

This philosophy aligns seamlessly with Dieter Rams’ ‘Ten Principles for Good Design,’ emphasising that products should be both functional and enduring. Auto Mossa also applies the principles of 5S lean manufacturing to maximise efficiency, reduce waste and optimise quality in every step of production.

ArchiPro spoke with Max Wills, Regional Sales Manager at Auto Mossa, to explore the meaning of designing for longevity and the crucial role high-quality materials and local support play in minimising environmental impact.

The Meaning of Designing for Longevity

For Auto Mossa, longevity is about more than just a product that lasts—it’s about engineering rapid doors that remain efficient and reliable long after their competitors have faded. As Max explains, “We focus on durability and performance, ensuring that our rapid doors operate smoothly with minimal maintenance while delivering long-term value to our customers."

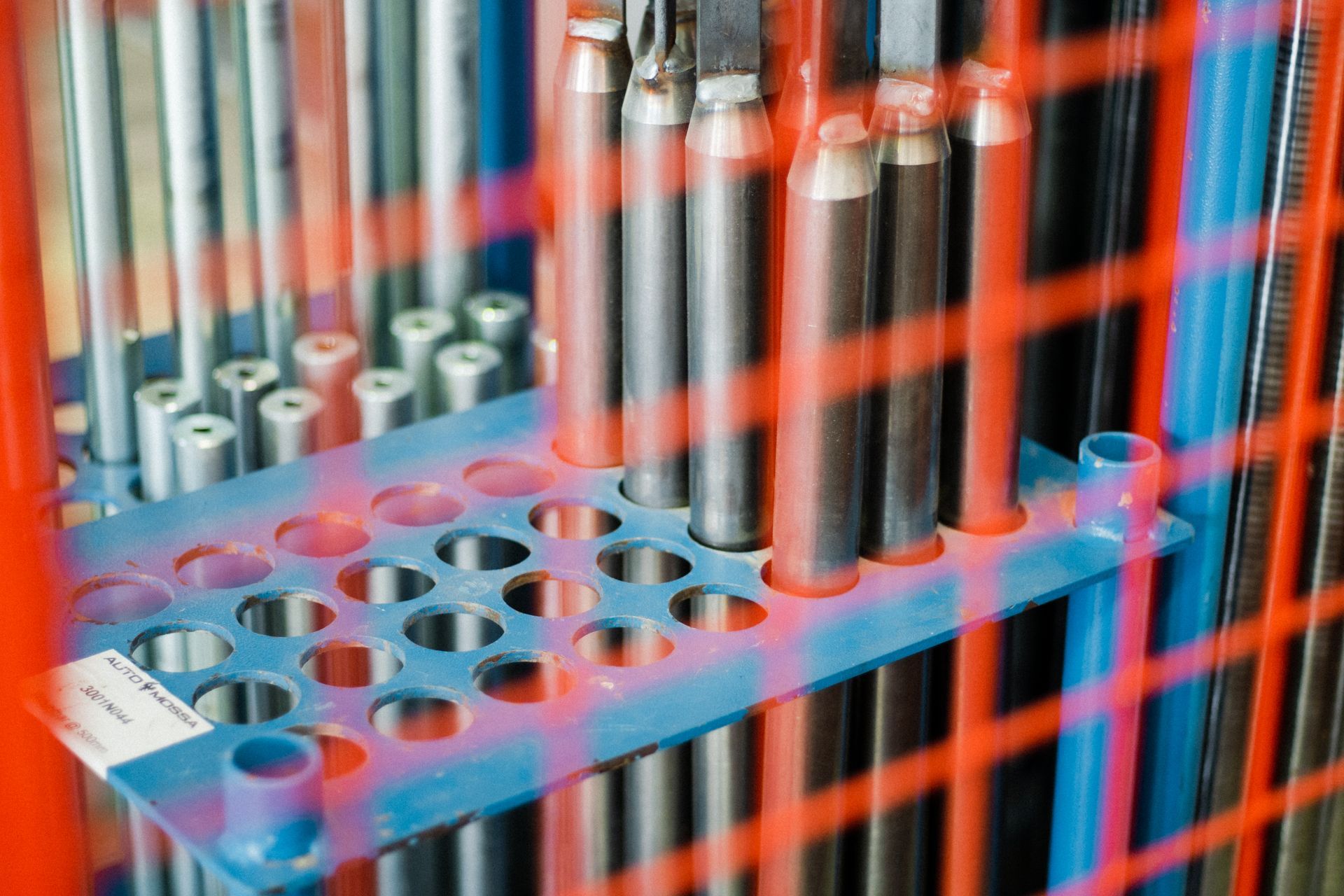

A core part of this longevity lies in Auto Mossa’s patented innovations. The Airstrip™ technology, for instance, is designed to create separation between the door curtain, making for a stronger, faster, cleaner and longer-lasting rapid door. Additionally, the auto-relocation feature allows the door to automatically realign itself after an impact, preventing downtime and costly repairs. “These features mean our doors don’t just last longer—they perform better, require less maintenance and keep businesses operating without interruption,” Max says.

The choice of materials further enhances longevity. High-quality, locally sourced materials ensure Auto Mossa’s rapid roller doors maintain structural integrity under demanding conditions, reducing the frequency of replacements and repairs. This not only minimises waste but also lowers the overall environmental footprint of the doors, making longevity a key component of sustainable design.

Local Manufacturing that Enhances Durability and Reduces Environmental Impact

A key part of Auto Mossa’s philosophy is local manufacturing. The company prides itself on designing, engineering, testing and producing all its rapid doors in New Zealand. This approach guarantees strict quality control measures and high production standards, ensuring that each door meets rigorous performance requirements.

Max explains, “Local manufacturing allows us to have complete oversight of the process. We can guarantee the quality of every rapid roller door that leaves our facility. Plus, producing locally means shorter shipping distances, which reduces our carbon footprint and supports the local economy—it’s a win-win.”

By manufacturing locally, Auto Mossa not only enhances the durability and quality of its rapid doors but also significantly reduces the environmental impact of transportation, which is often one of the highest contributors to a product’s overall carbon footprint.

Additionally, local manufacturing ensures a rapid response to customer needs. The ability to quickly adjust production lines and meet demand not only supports the efficiency of Auto Mossa’s supply chain but also minimises excess production and waste, helping to reduce overconsumption.

Innovation and Rigorous Testing: The Key to Longevity

Innovation is at the heart of Auto Mossa’s product development process. Each of its rapid doors includes patented components designed to maximise performance, efficiency and longevity. As Max notes, “Every patented design we create is a response to a real industry challenge. We’re not just making another version of an existing product—we’re developing something better, something that will last longer and perform more efficiently.”

Auto Mossa’s patented Airstrip™ technology enhances the durability of rapid roller doors by reducing friction and wear, resulting in a cleaner and longer-lasting solution. Meanwhile, the auto-relocation feature ensures that the door can continue operating even after an impact, reducing operational downtime and minimising maintenance requirements. These innovations provide businesses with a reliable and cost-effective solution that keeps operations running smoothly.

As mentioned, Auto Mossa follows the principles of 5S lean manufacturing, which focus on maximising productivity, reducing waste and ensuring top-tier quality. Max reinforces this by saying, “We don’t cut corners. Our rapid doors go through rigorous in-house testing to ensure they exceed industry standards. We want to make sure our customers are investing in something they can rely on for years to come.”

By incorporating innovation into every design, Auto Mossa can respond directly to emerging challenges, offering rapid roller doors that evolve in line with the latest industry standards and customer needs. Their commitment to performance and reliability, paired with their focus on high-quality materials, ensures doors that last, reducing the need for repairs or replacements and supporting a circular economy.

A Future Built to Last

Auto Mossa’s approach to rapid door design is a blueprint for longevity, finding the perfect balance between durability and sustainability. By focusing on high-quality materials, local manufacturing and continuous innovation, the company sets a new standard for how high-performance rapid doors can be engineered for long-term reliability.

Each Auto Mossa rapid roller door is crafted to endure, offering reliability, efficiency and peace of mind for years to come. With demand for products that are both environmentally responsible and built to last, Auto Mossa is leading the way, ensuring that their rapid doors continue to set new benchmarks in durability and performance.

Explore how Auto Mossa’s sustainable and cutting-edge rapid door solutions can support your next project by using the form below or enquiring directly through their ArchiPro Contact Page today.