Expanding 100-year-old villas with bespoke matched weatherboards

Written by

19 October 2022

•

4 min read

Along with brick, weatherboard is historically probably the most common cladding material in New Zealand. From the bungalows and villas built in the early 20th century up until today, it’s been a staple in Aotearoa’s rich history of residential construction.

Within the weatherboard category itself, there are many sub-variants: classic bevel back, probably the most common; rusticated; and vertical and horizontal shiplap. All of these types of weatherboards are still used today, whereas a century ago the material used was exclusively timber. Now fibre cement, vinyl and even metal can be used as a weatherboard material.

The introduction of new materials is not the only innovation the New Zealand weatherboard industry has seen – technology and new trends have changed the landscape since the weatherboards were first laid on those villas and bungalows built in the 1920s.

Of course many of these old villas are still around today, and are much loved and prized for their character and charm – so much so that most councils have instituted protected 'character zones' to ensure this character is upheld if any remediation or renovation is done on them.

While new weatherboards don’t always need to be matched with old ones when renovating, many homeowners may still opt to do this anyway to further conserve the house’s character. In many cases, though, this is easier said than done.

Clelands Timber: Experts in weatherboard matching

Not so for Clelands Timber, though. As a New Zealand-based company with roots in the timber industry dating back to 1916, it’s perhaps no surprise the company is uniquely proficient in matching timber weatherboards to houses built in the era of its founding.

Andy Watt, the sales manager at Clelands Timber, says the service they offer is a very valuable one for those aiming to improve their character homes.

“In a lot of these older villas, the specific weatherboard originally used just isn’t available anymore,” says Andy. “But often the customer wants the weatherboard to match the original profile perfectly. That’s where we come in.”

Andy says there are a few means at Clelands’ disposal to achieve this. Customers can send in a sketch or even a stencil impression of their weatherboard to the Clelands team: this is usually enough to get the ball rolling and gives the team all the information they need to replicate the board.

Otherwise, a digital drawing within a CAD system can be used, although this is far less common.

“Our favourite way to work, though, is if we receive a physical sample of what we’re trying to match,” says Andy. “But regardless of how we receive the sample, our in-house design team then creates a profile drawing to scale in their own CAD software – and this includes all the small details, like any weather grooves or anti-cupping grooves.”

A uniquely bespoke service

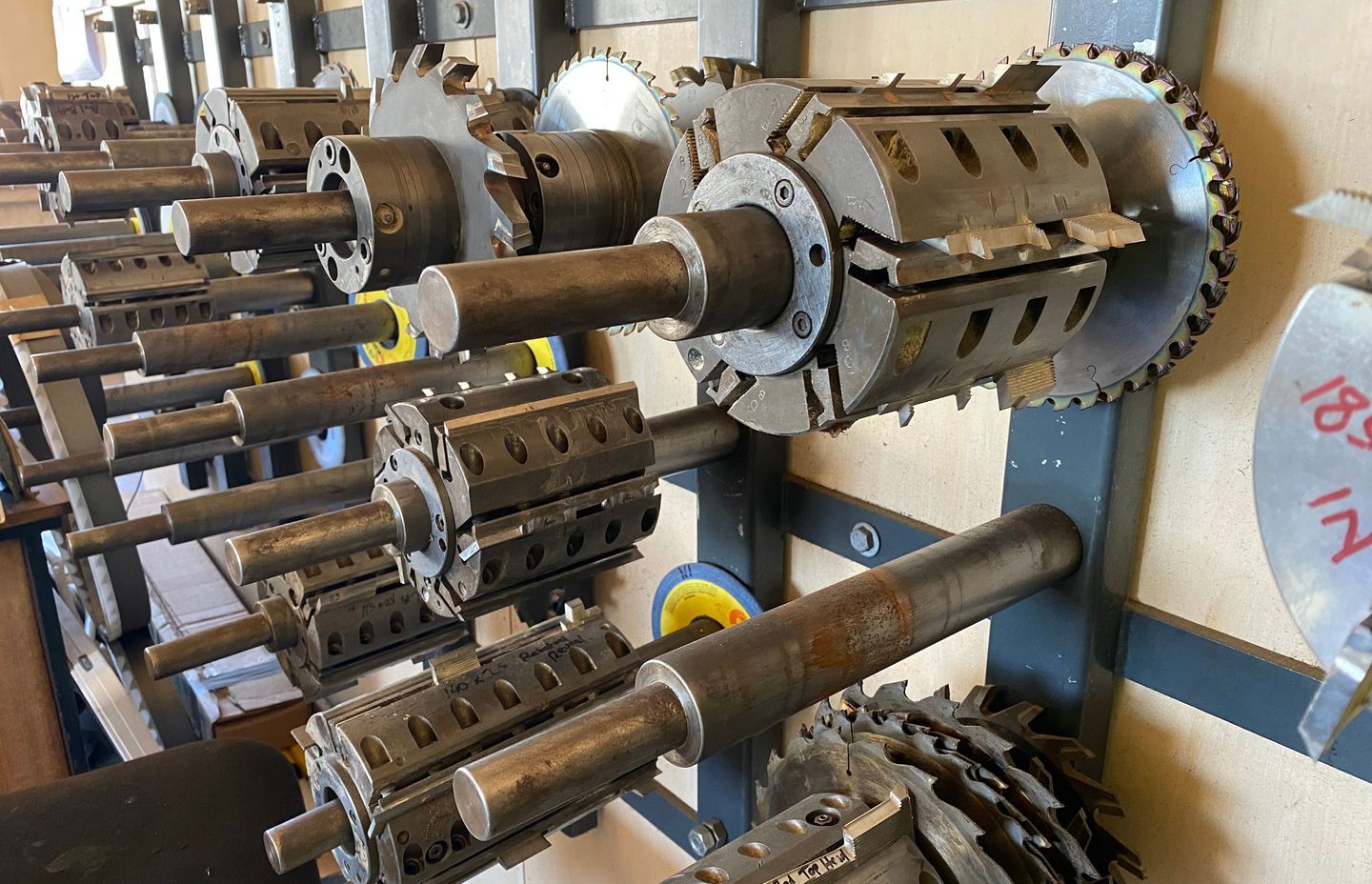

Clelands then sends this back to the customer with a quote and a request for approval – and then the concept gets inducted into the production process. The design team takes the CAD drawing and works in a dedicated tool room to create custom knives that go into Cleland’s planer machine.

“Our guys use templates and knife steel to create the blades that then run on the hands of the machine – and this is what creates the bespoke weatherboard,” says Andy. “And then, depending on the specific board, it’s either pre-primed or stained before it’s sent out the door.”

Andy says that while other weatherboard manufacturers may undergo similar processes, it’s not common to have such a custom, bespoke service such that Clelands offers – especially since the company accepts jobs that require as little as 100 metres of weatherboard, which is not industry standard.

And this is all because of the very real, sizable market for bespoke weatherboards matching homes that may be over 100 years old. “Our customers really value the idea of maintaining the same look if they’re extending their home,” says Andy.

“And this is one way that can do exactly that. People just wouldn't even know it’s a younger weatherboard by looking at it, because the product essentially is exactly the same – even though it's 100 years younger than the board that's been matched.”

Learn more about Clelands Timber and its products and offerings, and how it can help match your weatherboards.