Heat pump and hot water technology combine in new energy efficient water heating solution

Written by

21 November 2023

•

6 min read

Energy efficiency is a hot topic in the world of heat technology, and for many homeowners, it’s a key factor in the purchase decision process; not only do energy-efficient appliances have a lighter environmental footprint, they’re also kind to the wallet.

Looking long term at how New Zealand might deal with issues around energy availability and environmental change, coupled with the knowledge that homeowners are looking for hot water solutions that will have a minimal impact on their energy bills and the environment, Rinnai set out to develop a water heating system that ticked all the boxes.

Combining technology to create a new water heating system

The solution is called HydraHeat, an innovative water heating system that uses the efficiency of heat pump technology to heat hot water while saving up to 75% on water heating costs.

“Heat pump technology is a gift if you want to heat hot water, as it allows you to extract more energy from the heat pump than you put into the appliance to run it,” says John Swarbrick, Rinnai’s Technical and Innovation Manager.

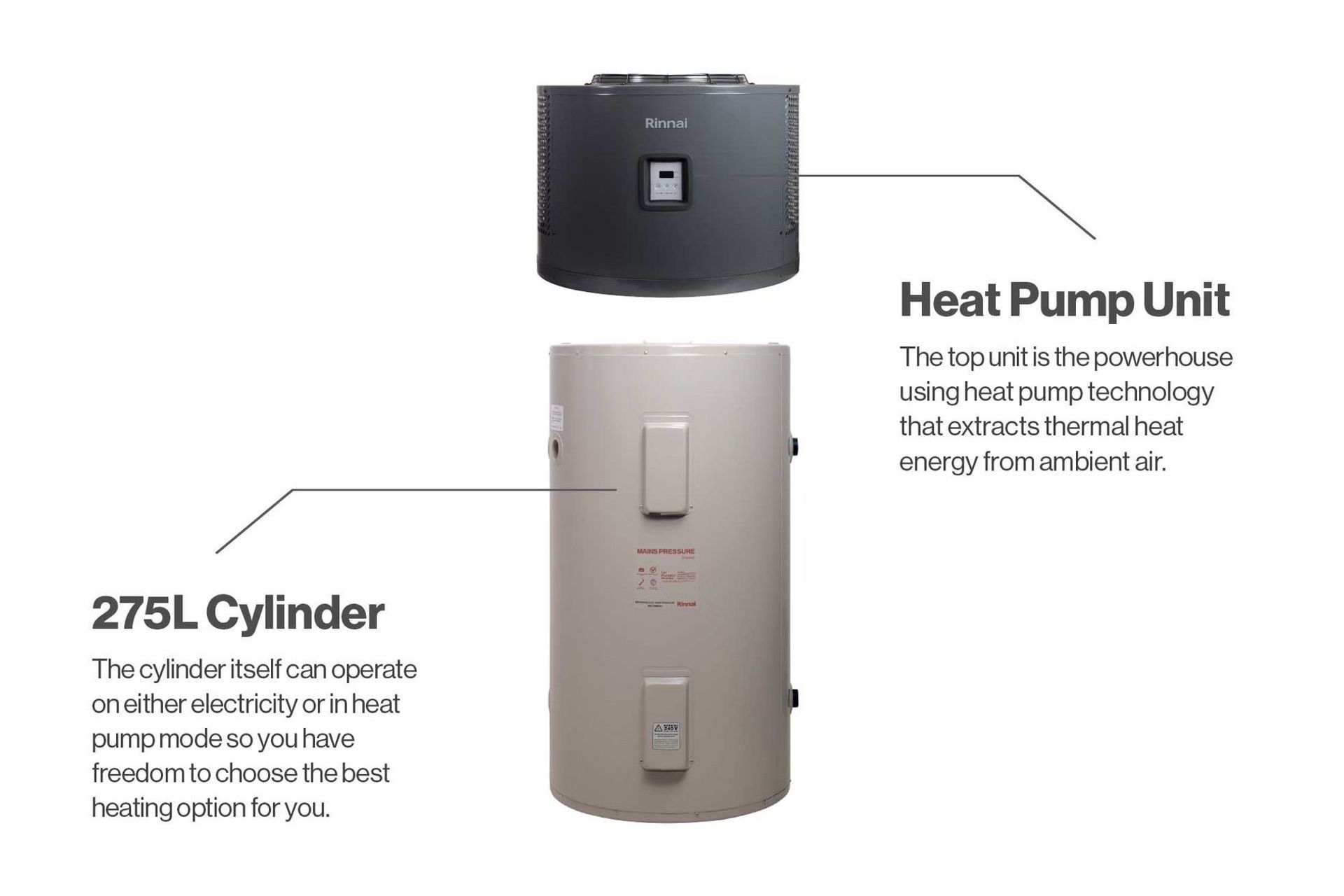

“Unlike other water heating technologies, we’re not generating heat, we’re simply moving heat from one place to another using heat transfer and refrigeration equipment. For the HydraHeat, this equipment has been placed into a removable head unit that sits on top of a hot water cylinder.”

In simple terms, heat from the atmosphere is absorbed into the refrigerant that flows through the HydraHeat head unit. At the base of the head unit is a heat exchanger, or condenser, that transfers the heat carried by the refrigerant to the water. The condenser is made from several layers of concentric copper pipe, chosen for its heat conducting abilities and stability with both the refrigerant and water. The refrigerant heats the copper pipe as it passes through, transferring the heat to the water, which flows through a smaller copper tube surrounded by refrigerant. As the hot water leaves the condenser, it enters the top of the hot water cylinder.

“This method is called ‘top down heating’,” Swarbrick explains. “We designed the cylinder this way, because in a stand alone hot water cylinder, the hot water is always drawn from the top. By injecting the hot water into the cylinder at the top, there is always hot water ready to use.”

Six operation modes for reliable hot water

The HydraHeat has six operation modes to support a range of different scenarios, ensuring you have hot water when and how you need it. In standard mode, the water is heated to 60 degrees using the heat pump unit only. The HydraHeat does have a standby element, designed to turn on in the case of heat pump unit failure, or when the temperature needs a temporary boost, but this is not activated in standard mode.

Boost mode uses the heat pump and element to drive the temperature up to 70 degrees temporarily, reheating the water in the cylinder as fast as possible. “This mode is great if you have people staying with you for the weekend. When everyone is having showers and there’s little hot water left, boost mode will heat the cylinder quickly, and then return to the previous mode to save on energy,” Swarbrick explains.

Eco 55 and 50 modes heat the water to 55 or 50 degrees respectively, using the heat pump only. In this mode, a weekly legionella disinfection cycle runs, heating the water to 60 degrees to prevent the growth of bacteria. In high usage mode, the tank heats to 70 degrees using the heat pump and element, but unlike boost mode, the tank will stay in this mode until a different one is selected. This is ideal for situations where you know you’ll have high demand for an extended period of time, giving you peace of mind that you’ll always have hot water on hand.

In element only mode, the heat pump is shut down, and the element is run as the only heat source. This mode guarantees you’ll have hot water even if there is a fault with the heat pump unit. Lastly, shutdown mode places the whole unit into standby so no heat is generated. This is ideal for baches or infrequently used properties where there is no demand for hot water. Once shutdown mode is switched off, it takes around four to six hours for the cylinder to heat up to full temperature.

A sustainable solution for Kiwi homes

Most conventional water heating systems have a 1:1 energy to heat ratio, meaning when you put one unit of energy into the appliance, you will have one unit of energy delivered to heat the water.

“With the HydraHeat, we can put one unit of energy into the appliance and get up to 4.7 units of energy delivered to heat the water, which means we use less energy to heat the same amount of water as a conventional water heater. From a sustainability point of view, this is great news, as the less energy used, the less we need to generate,” Swarbrick says.

Rinnai has also considered the environmental impact of materials used, opting for a refrigerant with a very low Global Warming Potential (GWP). “In simple terms, this refers to how much thermal radiation the gas would absorb and thus contribute to global warming. The lower the GWP of a refrigerant, the less impact it has. In HydraHeat we use R290 refrigerant which has a GWP of 3.3. Compared to other refrigerants like R32 that has a GWP of 632, and R410a that has a GWP of 1900, it’s a no-brainer.”

Thinking about the lifecycle of the product, Rinnai has designed the HydraHeat unit to be easily serviced. More conventional hot water heat pumps often have a permanently connected head and tank, making them difficult to repair. As the HydraHeat head and cylinder are separate parts, they can be fixed or replaced if anything goes wrong, reducing the need to dispose of the unit prematurely.

Rinnai are looking forward to the market launch of HydraHeat, coming late-2023. “We’re excited to see it appear on plans and specifications, and I’ve promised our research and development team a morning tea shout when the first set of plans come through!”

Learn more about Rinnai or fill in the form with any questions and we’ll get back to you as soon as possible.