How do we select our stone?

As importers and suppliers of natural stone our team regularly visits stone quarries throughout the world. But, how do we choose the right block from a quarry, how is it processed and how does that block of stone find its way to our warehouse?

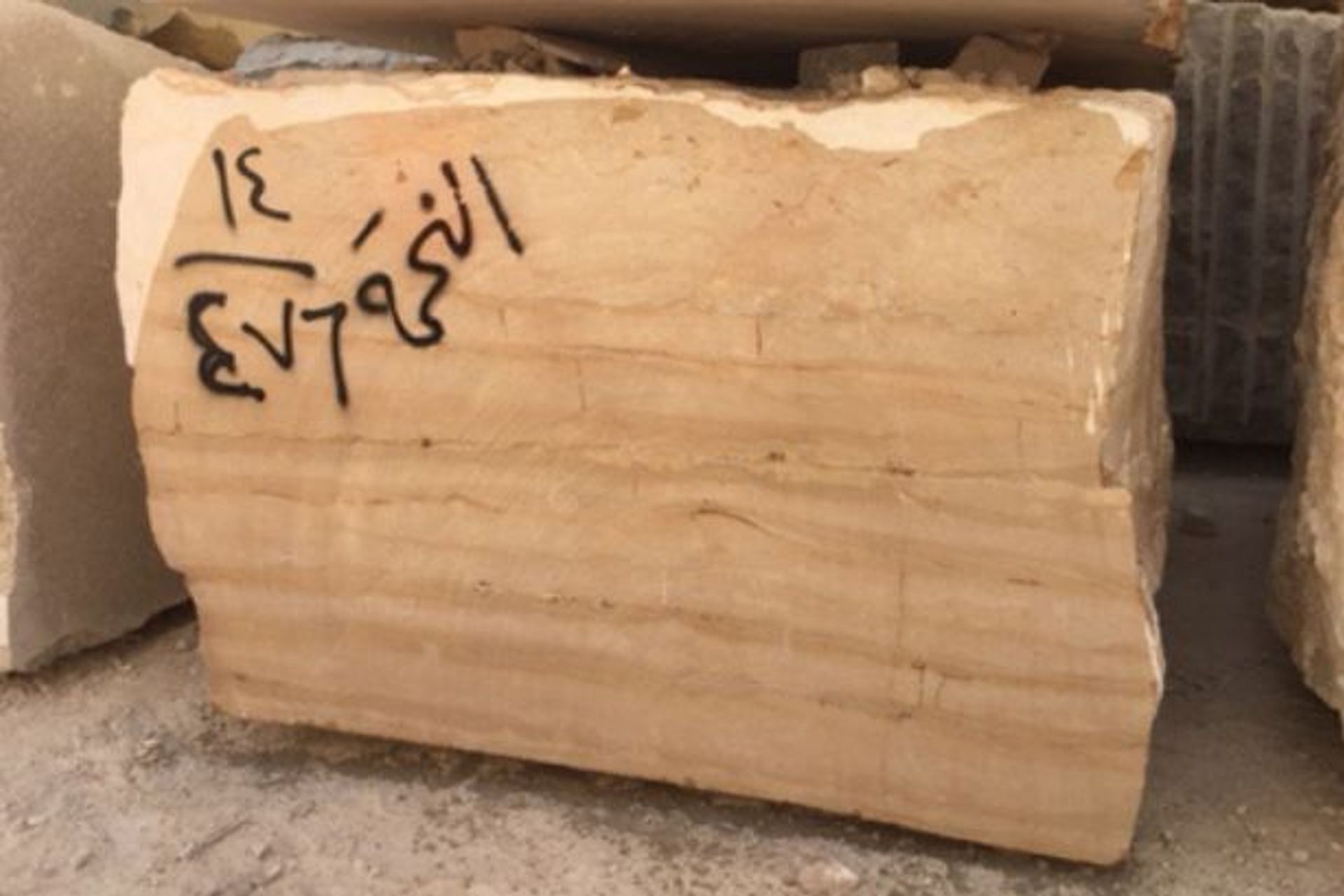

Finding the Right Block of Stone

What do we look for in a block? There are many characteristics we look for in a block of stone but predominantly colour, mineral deposits and veining and importantly we check for defects or cracks. It’s also important we know what the block will be used for – for example will it need to be honed or polished and what is it going to be used for – will it be slabs or bench top material, flooring or walling?

Cutting the Stone

The block is then cut into slabs using machines such as gang saws. This can be a time-consuming process and, depending on the density of the material, can take up to 6 hours to cut a full block.

The stone then goes through a milling (calibrating) machine. The slabs or tiles and pavers are calibrated to within +/- 1-2mm tolerance thickness. Like the cutting, calibrating is also a time-consuming process which is necessary to deliver a high quality product. The slabs are then sold as slabs if suitable or where they’re not suitable are cut into tiles or pavers.

Finishing the Stone

The finish is then applied to the tiles and pavers. Different types of natural stone are finished differently based initially on the hardness of the stone and with consideration for the final application for the stone. For example, limestone is relatively softer than granite and therefore will be treated differently. Marble is predominantly used indoors and is treated differently to sandstone which is used inside and out.

Packing the stone

One more all-important final check is made and then all is packed securely ready for the journey to our warehouse.

Shipping the stone

The stone is shipped, usually from the other side of the world, to Port Botany in Sydney. The shipping process can take anywhere from 4 to 12 weeks, sometimes longer.