How is Weathertex Made?

While the Weathertex factory is over 60 years old, our manufacturing process is up to date and is quite a unique process! Weathertex’s dedication to innovation and sustainability is evident through a unique steam-heated compression technology that converts sustainably sourced Australian hardwoods into durable, weather-resistant cladding solutions. Let's walk you through it.

Step 1-2- PEFC certified

Weathertex sources timber from REAL timber harvested from sustainably harvestedPEFC certified and controlled sources. This careful selection ensures that everyweatherboard and architectural panel begins with the highest quality Australianhardwood, setting the foundation for superior exterior cladding panels. Our logs arethen reduced to chips using a high-volume chipping machine.

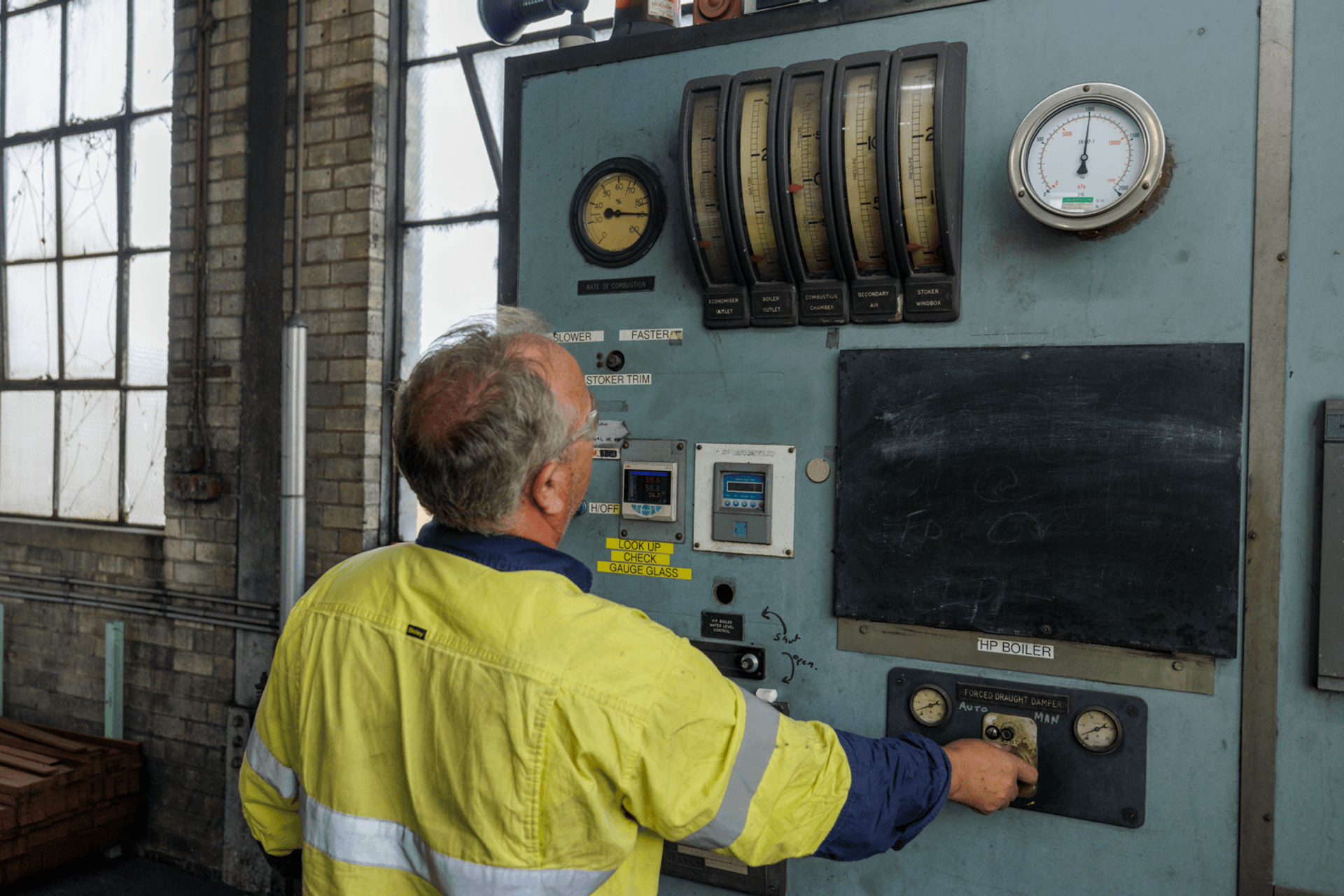

Steps 3-4 Revolutionary Steam Treatment

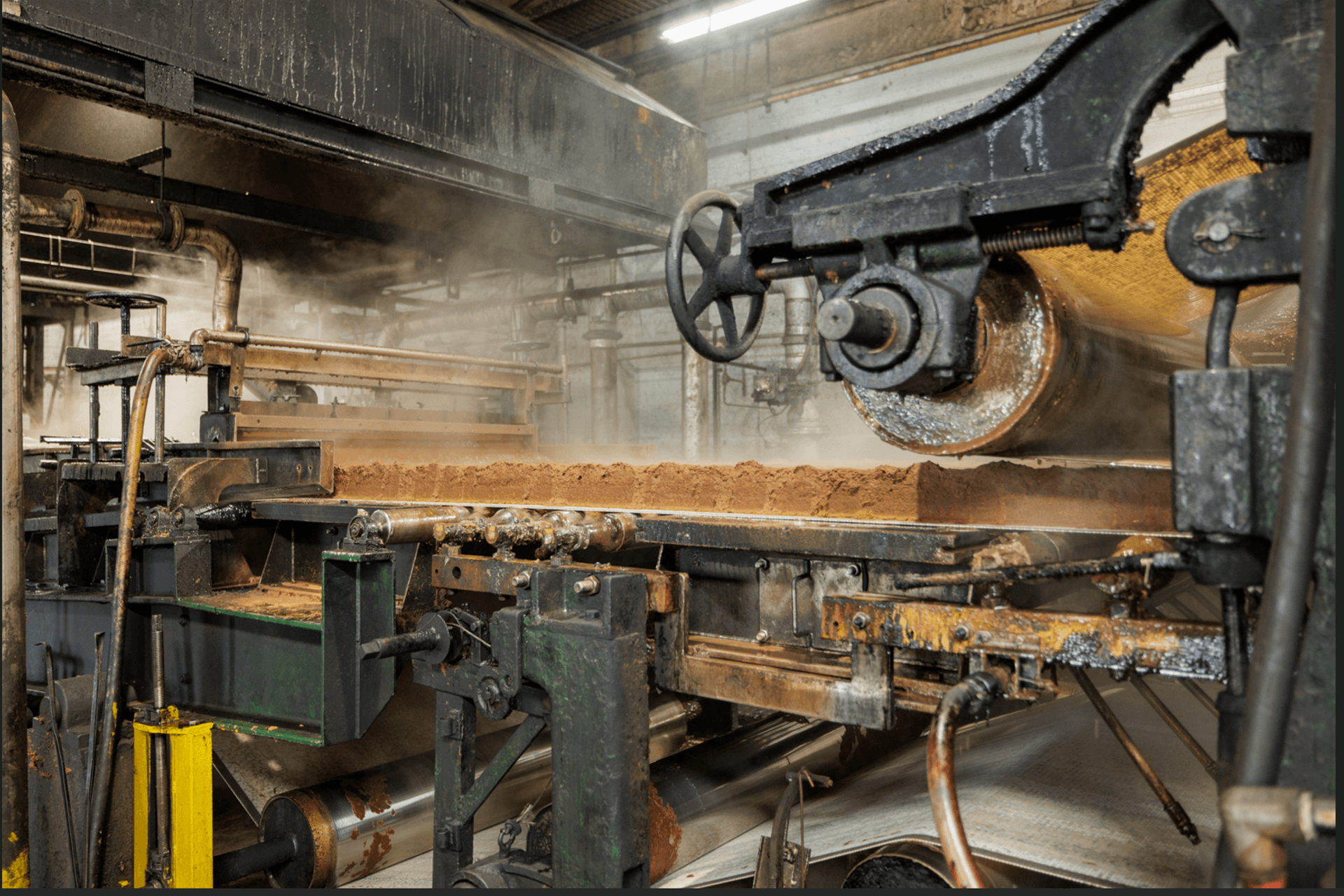

The woodchips are fired, using high-pressure steam, through the Mason guns, theonly two of their type in the world! We then star our wet process that adds 3% waxand water to the fibres passing through a board machine and reconstituted intowhat is known as “wet lap”

Steps 5-8 Advanced Compression Technology

At this stage, the “wet lap” is approximately 60% moisture and around 35mm thick.

The “wet-lap” is then fed into the hydraulic press, where steam platens “cook” the

finished sheets. Stainless steel and nickel plates are used in the press to emboss our

textures. The sheets emerge from the press, now having been reduced to around

10mm thickness.

Steps 9-10:

Planning & ProfileCutting

After sorting by textures, sheets are humidified and processed through the planer toensure all cladding panels are exactly 9.5mm thick. The sheets are then processedinto weatherboards or architectural panels using a multisaw and grooverequipment.

Steps 11-13: Priming & Curing

The sheets become profiled Weathertex weatherboards or architectural panels. OurPreprimed range receives its first primer coating before entering infrared ovens tocure at temperatures exceeding 70°C. Quality control teams grade allweatherboards and panels as they exit the paint line.

Steps 14-16: Primelok System &Packaging

Weathertex's innovative Primelok system utilises a special spline machine to insertsplines into boards for superior cladding installation. Almost ready for dispatch,Weathertex is packed and wrapped using orbital plastic wrapping machines beforebeginning its journey to warehouses and building projects throughout Australia andthe world.