How to know your tiler is using best practices

Written by

16 March 2023

•

5 min read

The difference between a beautiful tiling job and one that is sub-par isn’t always easy to spot from looking at the finished product. That’s because there’s so much preparation work involved in tiling (as there is with timber and vinyl), and it's the prep work that creates a foundation for tiling that won’t fail, leak or crack down the track.

So how do you know your tiler is adhering (excuse the pun) to best practice guidelines? Global Tile managing director Jared Caldwell says it’s very tricky in New Zealand, because anyone can pick up a trowel and say they're a tiler, even if they know nothing about it.

“Australia's quite a different kettle of fish from New Zealand in that they encourage those that want to become a tiler to attend TAFE (Technical and Further Education) to become certified as a tiler.”

The Australia/New Zealand (AS/NZ) standards are published guidelines for tilers to follow. Many of these standards are integrated into New Zealand’s Good Practice Guide: Tiling, published by BRANZ, and this provides a good framework for tiling standards in the local industry.

However changes are afoot in Australia to make some standards mandatory, of which one will be surface preparation. Jared says this will likely be reflected in the New Zealand Good Practice Guide in the near future.

Surface preparation standards

Whatever surface your tiler is preparing – whether it’s fibre cement sheet or concrete – if they don’t get the surface prep right, this could affect the overall installation, particularly where a waterproofing membrane is to be applied.

“It's absolutely critical that we get that substrate prep right so that we get a better bond with the material we're putting on top. We need to make sure there's no dust, no dirt, oils, paint, sealants, or anything that can inhibit the bond of adhesives, waterproofing membranes, or self-levelling underlays,” says Jared.

Aside from creating a clean, textured surface, your tiler should ensure the surface is dead level, because a tile doesn’t deviate and won’t go over a hump in the floor.

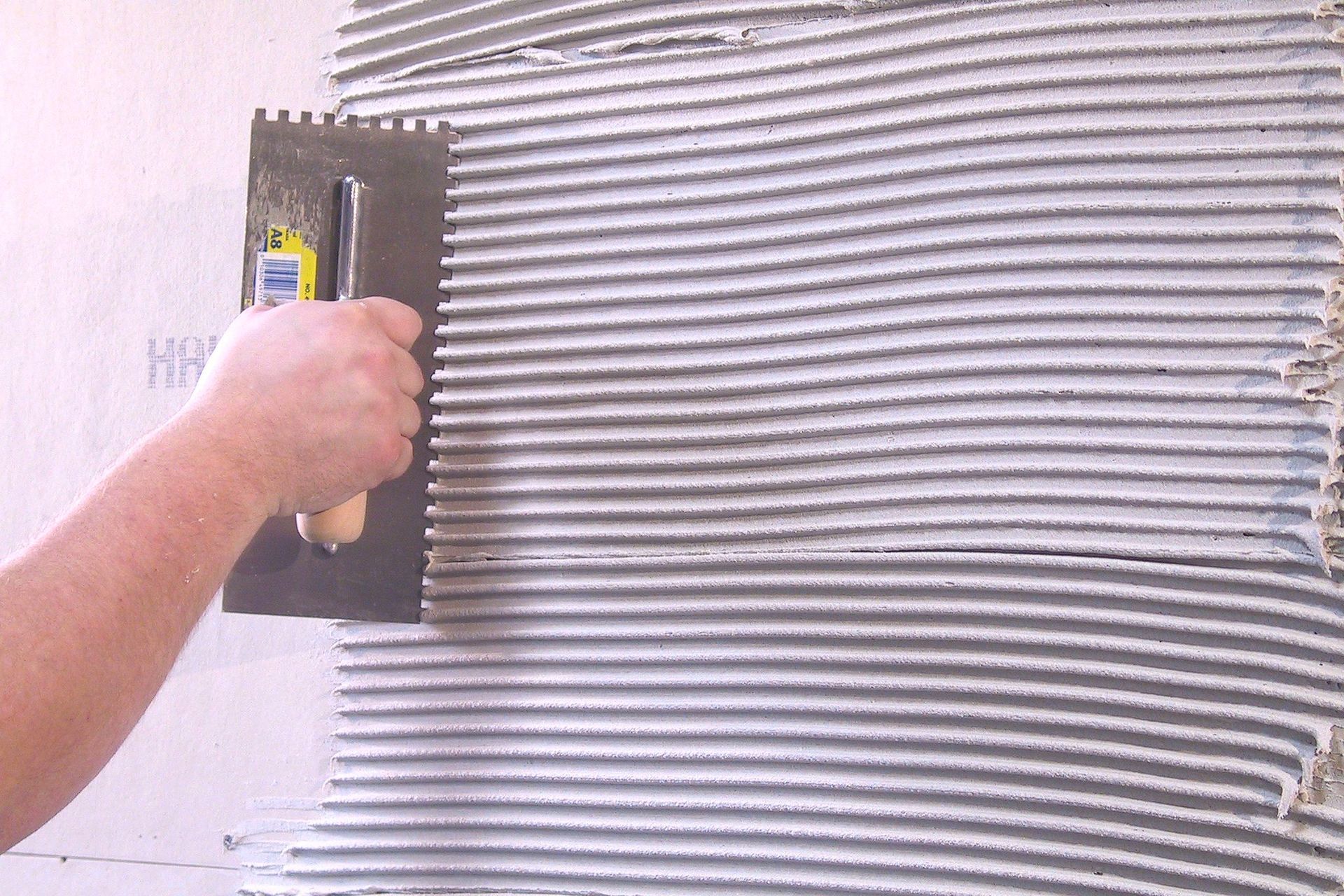

The first aspect of preparation is the texture of the surface. In the US, Australia and other parts of the world, good practice standards define the level of surface texture that is recommended for a membrane or adhesive to bond properly.

“A concrete surface profile (CSP) goes from one – being smooth – to 10 – being fairly rough. The Australian standards are now calling for a CSP3 surface finish for tiling, which is the right finish to achieve a decent mechanical bond.”

The reason for this is if your concrete has a glassy smooth finish, for example, you’ll get very little bond as the pores of the concrete surface tend to be tight and closed.

“We don't want the concrete to be glassy smooth – we need the pores of the concrete open and we need a slight amount of texture for a self-levelling underlayment, waterproof membrane or tile adhesive to have something to grab on to.”

Jared recommends asking your tiler what level of finish they intend to achieve.

“That way, you’ll know that they’re adhering to best practice guidelines. Also ask your tiler about what kind of leveling preparation will be needed as it’s an extra cost, but it’s essential for floors that aren’t completely level.”

Tile adhesives are not designed to be used as a packer under tile to remove unevenness in the floor or walls.

“Some tilers don’t realise that they can save themselves time and money by installing a self-levelling underlayment like LATICRETE Level on floors. This will also provide the end user with a much better installation long term.”

What combo of adhesives and water-proofing membrane are you using?

There are two reasons why this question is important: the first is that using products not designed to interact with each other can cause a failure, and second, using a full system from one supplier like LATICRETE means you won’t accidentally void the warranty.

“You may choose to use our water-proofing membrane – LATICRETE Hydro Ban – but then a tiler might come along and use someone else's adhesive, which they may have purchased because it was cheaper than the specified product. But there can be compatibility issues between brands. If there's a failure, then everyone goes to site and says, ‘Whose adhesive is that on top of my membrane? We can't warranty the claim.’ It's critical to use a full system."

To that end, the LATICRETE system has been around for over 66 years, is suitable for installations inside and out as well as swimming pools, commercial and residential. It’s considered to be a comprehensive and complete system and is backed by warranties.

“We've been distributing it for years and to date haven’t had any warranty claims.”

Discover more tile products from by Global Tile