It's a lock

Written by

01 September 2020

•

4 min read

New Zealand has a global reputation for “punching above its weight” across many different sectors, most prominently in the high-profile areas of sports and film. There are, however, hundreds of Kiwi businesses whose products and reputations are household names in their fields—both here and overseas.

One such company is Halliday + Baillie, who have been designing, manufacturing and supplying a range of hardware products to the residential and commercial markets for a quarter of a century.

“Since our inception, we’ve grown our product range to the point where we now offer over 200 products, most of which come in a variety of finishes and are exported to Australia, the USA, the UK, Europe and the Middle East,” says Director, Tiffiny Hodgson.

“We began exporting our products to the USA around 16 years ago and have experienced remarkable growth in that market, where we’re viewed as a high-end supplier offering a superior product both in terms of design and craftsmanship. We have also opened offices in Western Australia and in Sydney.”

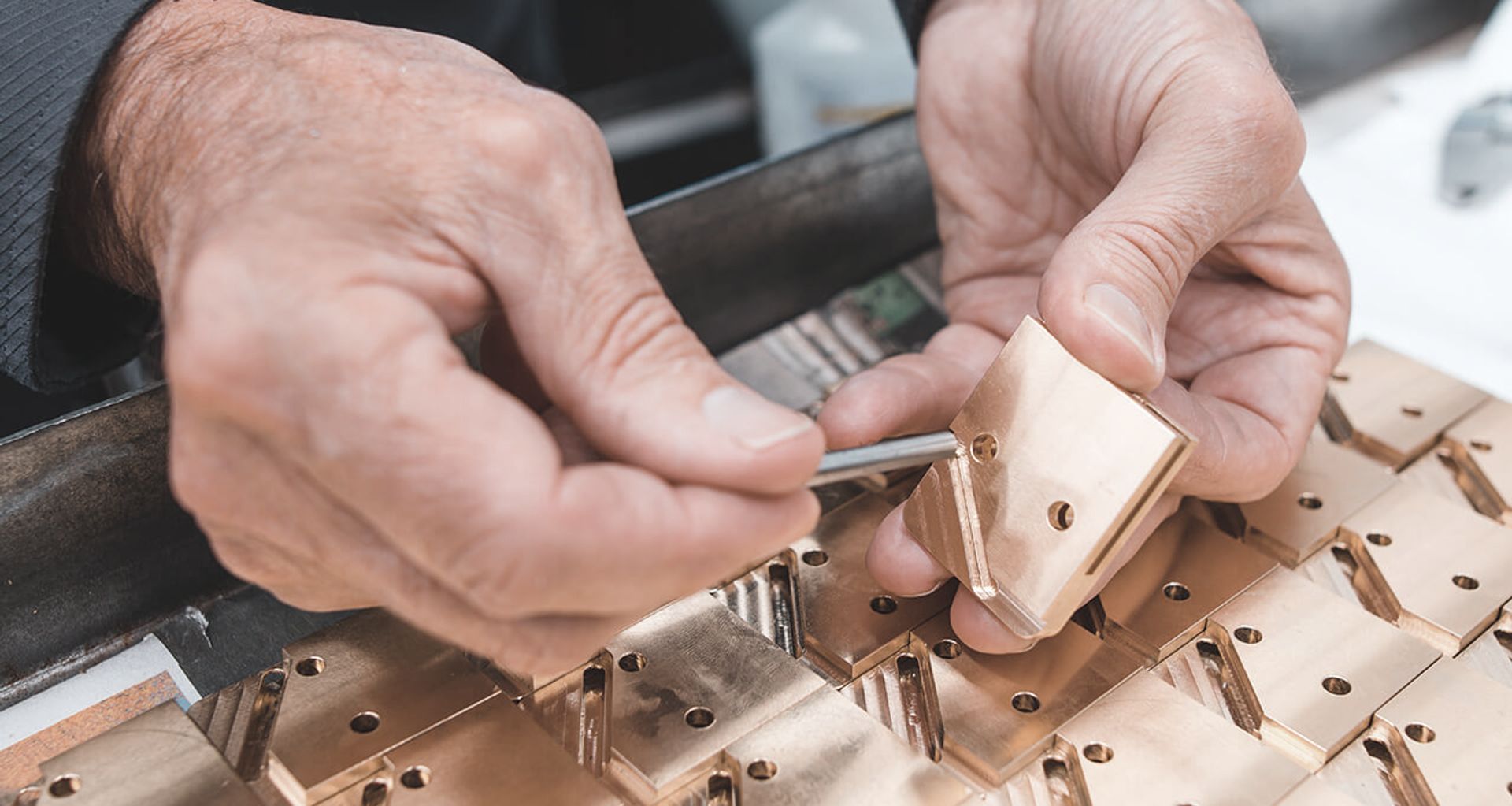

Proudly made in New Zealand

“All of our products are manufactured in New Zealand in conjunction with a number of local producers—tool makers, die casters, engineers, electroplaters, powder coaters—all of whom are within 20kms of our Auckland showroom.

“Our success, internationally, comes down to our commitment to our New Zealand supply chain and to the high standards that both we and the people we work with hold ourselves to. US distributors and wholesalers see New Zealand businesses as being highly innovative and are particularly attracted to our transparent laws and regulations.”

Tiffiny says Halliday + Baillie has been working with its US representatives on a new product, which the company is looking to launch in the next two months.

“We were about 50 per cent of the way through the process of getting a new product ready for the US market when COVID-19 struck and we went into lock down. Fortunately, we were able to keep the lines of communication open via video conferencing, which allowed us to forge ahead with our plans for distribution.

“It helps that we have a strong relationship with our US-based partners. The US market is a hard one to break into—not least of which being that each state has its own regulations and standards—and unless you have someone on the ground there you can trust, it is almost impossible.

“We’re also benefiting from the fact that all of our componentry is made in New Zealand, this has allowed us to keep pushing forward with this project and is the main reason why we will be launching in October.”

Halliday + Baillie: opening doors in the US

Tiffiny says the process for this new product has been a journey of around eight months, some of which has involved working through the specific requirements for launching a new product in the USA. For the New Zealand and Australian markets, getting a product from concept to market release generally takes just 3–4 months; again, most of that mitigated by the local manufacture of the products and our great working relationships with our fabrication partners, who often drop everything to help ensure the timely delivery of products.

“While this particular product, which is a lock system for pivoting doors, has been specifically tailored to the US market, we will be releasing it within New Zealand and Australia, in keeping with our policy of ensuring that all of our products can be used in concert with each other.

“Like all our products it is constructed from 316 stainless steel and architectural-grade brass with New Zealand conditions in mind. We believe if our products can stand up to New Zealand’s harsh environment, they will stand up to anything the rest of the world can throw at them.”

The lock will initially be offered in one size and a range of five finishes and all going to plan will be available in various sizes in the not too distant future.

Learn more about the products offered by Halliday + Baillie.