Keeping it local

Written by

16 September 2021

•

6 min read

When Sir Edward Coke pronounced in The Institutes of the Laws of England in 1628: "For a man's house is his castle, and each man's home is his safest refuge”, he was upholding a strong-held belief, one that continues to this day, that every homeowner had the right to deny any person, commoner or King, access to his home.

While the homeowners of the 17th century had the law to keep unwanted visitors from their homes, we’ve gone one step further and have employed ever more sophisticated locks and mechanisms to help keep our homes secure.

Taking its role in the security industry seriously, Allegion New Zealand continually strives for excellence in developing cutting-edge products to keep people safe and secure in their homes and places of work.

“Allegion is committed to providing products and services of the highest quality, tailored to suit your individual building needs and combining the elements of design, specification, manufacture, and supply. Allegion is well positioned to meet changing market requirements, thanks to our local manufacturing capabilities and complementary suite of international brands,” says Allegion New Zealand National Sales Manager—Residential, Bryce Carter.

“While mechanical hardware is the foundation of our business and will always be at the core of what we do, we recognise that the future lies in addressing the needs of an increasingly connected world. The rapid rise in the IoT since 2010 has strengthened Allegion’s focus on connected locking solutions, with an award-winning product Schlage Encode™ becoming an integral part of our range.”

Bryce notes that the drive towards greater functionality and accessibility has seen definite growth in this market, which in turn has led to greater compatibility and affordability that even includes the trend towards the integration of entry-level smart home packages in affordable housing schemes.

“Electronic solutions don’t replace our mechanical products, but a seamless integration of the two makes them more powerful. That’s why our core strength in mechanical security, when combined with digital, mobile, smart solutions, along with our expertise in style and design make us a leader in our markets.”

Allegion: redefining security through new technology

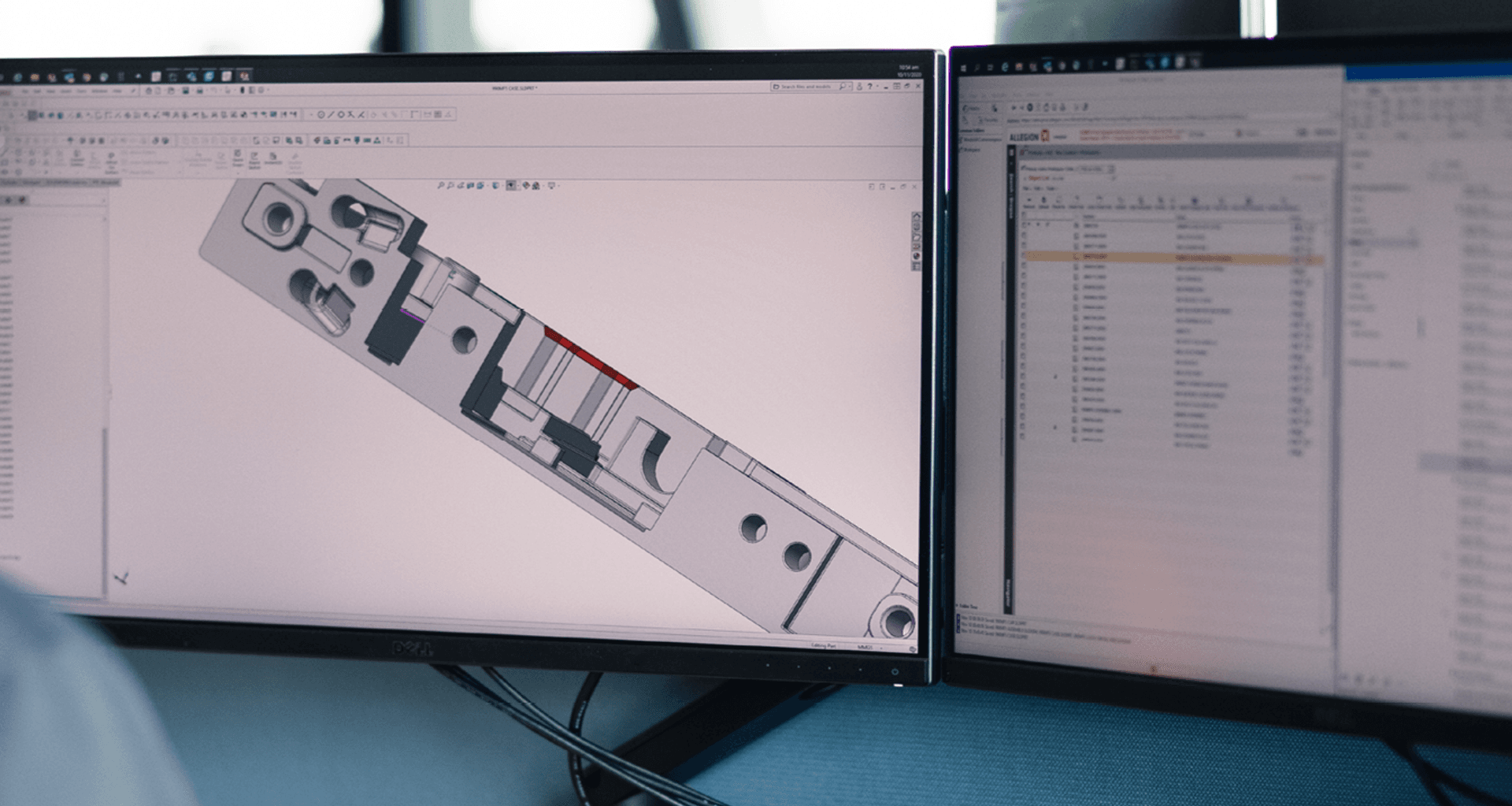

To consistently design and develop safety and security solutions, Allegion’s local product development and product management teams work closely together to proactively elicit customer feedback, conduct market research and seek inspiration from current trends. All with the goal of meeting customers’ hardware security needs.

Allegion New Zealand Product Development Manager, Jeremy Gear explains: “While our customers may be able to easily describe the problem they have, they don’t necessarily know what the best solution would be. Thus, identifying the best answer to the problem is the critical challenge and where design thinking helps bridge the gap between Allegion and our customers’ needs.”

“Allegion’s QuickFix™ technology is a good example of this. We were getting consistent feedback that our customers needed a fast and easy way to install door hardware—especially in the commercial and multi-unit residential markets. QuickFix is the solution; revolutionising the fixing mechanism for faster door hardware installation and reduced labour costs for end users.”

Bryce adds that: “The market response to QuickFix has been a great result for us and is further validation of our process. From a sales perspective, it is a very powerful tool to be able to inform our customers about the amount of research and development carried out at the design phase of this and all of Allegion’s products, not to mention the ongoing testing, which starts at design validation right through development.”

Allegion’s product testing includes the use of computer-aided tools that simulate physical loads placed on the product to identify any weak points in the designs. This is then fed back into the product design to improve the end solution and to make prototypes.

“We test our products so that we and our customers have confidence they are suitable for the physical demands they will be placed under when in use. We aim to provide peace of mind for our customers and to make it easy for them to stand behind our product in their projects,” says Jeremy.

Allegion: in the pursuit of excellence

Wherever possible, Allegion looks to test above and beyond the requirements defined in market standards. This gives the company and its customers extra peace of mind. An example is Allegion’s trusted Legge 990 Series mortice lock that will regularly test in excess of one million door opening and closing cycles, double the requirement of the highest certification level in both the Australian and New Zealand standards.

Bryce asserts that: “This attention to quality doesn’t just rest with functionality, either. For me, hardware is something you interact with every day and I’m reminded of Finnish architect Juhani Pallasmaa’s quote—‘The door handle is the handshake of the building’. It has the ability to create an impact at the entrance to your home and to set the tone of a room."

To further set itself apart in the market, Allegion New Zealand offers a selection of special finishes to complement architectural designs. These will be produced in-house within its state-of-the-art automated electroplating plant to help ensure a faster turnaround, quality control, environmental respect and the ability to accommodate special requests.

"In the coming months, we will be looking to continue supporting the growing trend of electronic and mechanical solutions by increasing the depth of range and finishes offered; continue to grow and deliver to the commercial and residential markets; and, continue to invest in the electroplating plant to maintain high environmental standards,” states Bryce.

Based in Auckland, Allegion New Zealand has a nationwide network of distributors including commercial hardware specialists, ‘big box’ retailers and trade merchants. Allegion’s team of technically trained architectural consultants is available to assist in the increasingly technical areas of product specification and door hardware scheduling, along with the company’s online specification collaboration tool, Overtur.

Learn more about the comprehensive range of quality mechanical and connected hardware solutions available for your next residential or commercial project.