Know your carbon numbers with Firth EcoMix Low Carbon Concrete

An increasing number of designers are looking to understand what building for climate change means. It’s often talked about, but can be hard to fully define exactly what it means when designing a building. Because building projects in NZ are so unique, our approach to sustainable design should also be unique to the project, which can make a definition difficult. It’s most important to take a holistic view to the project, looking with a whole of life approach, as most structures in the built environment are for intergenerational use.

As New Zealand’s leading concrete manufacturer Firth have been deeply engaged in the conversation about how to design for climate change with concrete.

Concrete has many benefits including:

- Long product life, with low maintenance requirements

- Durability – hence its use in foundations, garages, retaining structures, infrastructure, and industrial floors

- Fire resistance

- Good sound attenuation properties

- Hardscape applications, Permeable mixes are achievable along with additional attributes of storm water control and water quality benefits.

- It has the ability to store heat due to its thermal mass, so is often used where building comfort is a consideration.

These benefits combined with good availability, excellent quality control, and cost competitiveness make concrete construction an attractive proposition. However, as with all materials, there are aspects of the report card which read “could do better”. A focus for the concrete industry for some time has been ways to reduce the carbon footprint of concrete.

A carbon footprint is a colloquial term for the Global Warming Potential (GWP) of a material or product. It is expressed as a number of kilograms per CO2 equivalence (CO2e). The equivalence refers to converting the impact to global warming of a range of gases to that of carbon dioxide. For example, 1 kg of methane is approximately equivalent to 24 kg of CO2 in terms of global warming potential.

This is why it’s important to know the number. You may see many claims about reductions in the percentage of embodied carbon (CO2e), but what does this mean? Without knowing the reference number that reduction comes from it’s impossible to know if that’s the best option for reducing carbon. Instead it’s best to look for the GWP number. So where do you find that? Well the easiest is to refer to an Environmental Product Declaration (EPD). These are third party verified documents that let you know the Global Warming Potential of a product, and whether it meets the requirements of your project.

The concrete industry is working hard to reduce their carbon emissions through the use of lower carbon cements (such as EcoSure from Golden Bay) and Supplementary Cementitious Materials in the mix design.

Concrete is a relatively unique material in that the mix design is determined for each project. So, although the 28-day strength is the universal specified requirement, there are a range of other attributes the construction and design team may be wanting. For example, early strength may be important to allow lifting, or there may be a need to create a very flowable or cohesive mix to allow placement in piles, or aggressive exposure conditions may dictate the mix ingredients. All of these requirements can have an impact on how the mix is designed, and the GWP of the finished concrete.

So, if you want lower-carbon concrete, how should you specify it?

As a designer or engineer it’s not your job to know how much less cement to use, or what SCM is needed to get the lowest carbon, your job is to know what strength you want for your concrete and your GWP target.

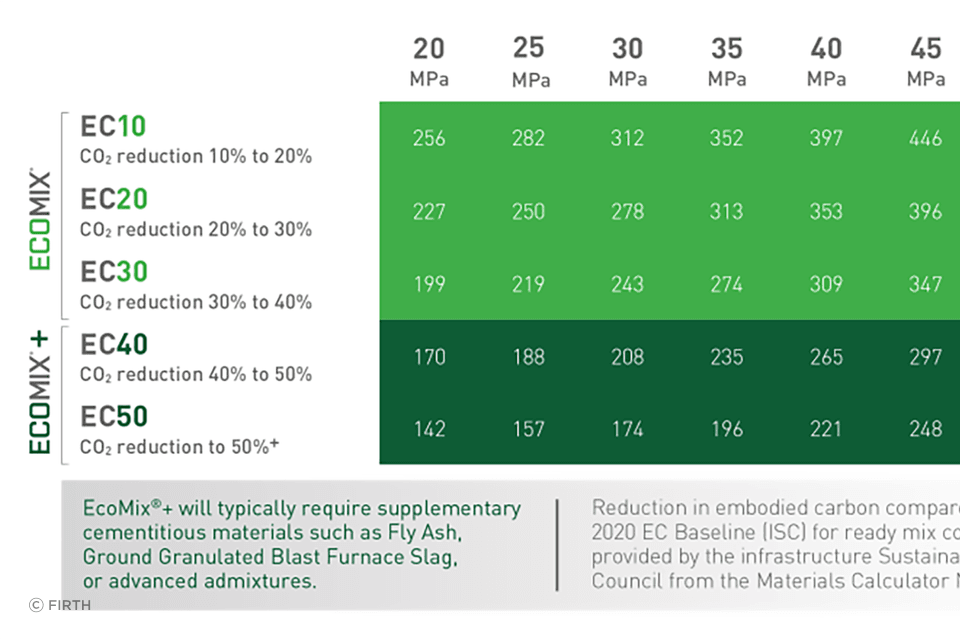

Just add these numbers into your specification, alternatively, we've developed an EC (Embodied Carbon) rating system to make specification writing easy.

You can also use the table below which shows GWP targets for a variety of concrete strengths. With NZ manufactured cement it is generally possible to achieve GWP values close to or below Firth’s EcoMix EC20 rating. Firth’s EcoMix EC30 and EC40 can be achieved with project-specific mix designs. Designers should set the GWP (with consultation with their local suppliers) and then let the concrete suppliers determine the most economical and safest method of achieving the targets.

Designers should avoid specifying the ingredients to go into a concrete mix design. This is fraught with potential liability and often does not achieve the desired result as low carbon ingredient does not always result in a low carbon concrete mix. Leave mix design to the experts and simply set the target GWP number. Beware however, that year on year the GWP number which can be achieved cost effectively is lowering. Investment by Golden Bay in NZs only cement manufacturing plant, means that the already world best practice GWP is getting lower for NZ made cement. Additionally, admixture technology is refining, and supplementary cementitious products are becoming more available.

So as a designer, remember to specify strength and then a maximum GWP number e.g. 30MPa, with a maximum cradle to gate GWP of 278kg CO2e/m3, and then chat to your local Firth representative on what is achievable in your area to meet your client’s needs. It is possible to build with concrete and reduce your carbon footprint, and Firth can help you every step of the way. Collaboration is key.