Local brick proves to be a stellar performer

Written by

17 August 2021

•

3 min read

Like many companies forced to scale back production during the 2020 lockdown, ViBlock used that time to take stock of its offering and to look for new avenues within the market to keep the business viable.

Previously, the manufacturer and supplier of architectural masonry blocks, pavers and retaining wall products, had concentrated on a range of masonry blocks known as its 90 Series products—so named because their depth is 90mm—including fairface, fluted, split face, rumbled, honed and textured blocks.

“During lockdown the company was looking for ways to keep the operation busy to retain all staff. We decided to expand into the 70mm brick market, which is a more mainstream, high-volume approach compared to the boutique architectural products for which we’re known,” says Jim Hunter, General Manager of ViBlock, which has been manufacturing high-quality masonry veneers for 15 years.

Decision made, four months later the $100,000-plus moulds arrived from the US and Kiwibricks was launched.

Being lighter and with a slimmer profile than their 90 Series stablemates, Kiwibricks are an alternative to other lighter-weight cladding options such as clay bricks, iron or timber cladding, says Jim.

“The ‘70 Series’ market was a natural progression. We often had customers coming to us with plans for their build only to find their foundation was only capable of taking a 70mm product and not the larger, heavier 90mm products we produced.”

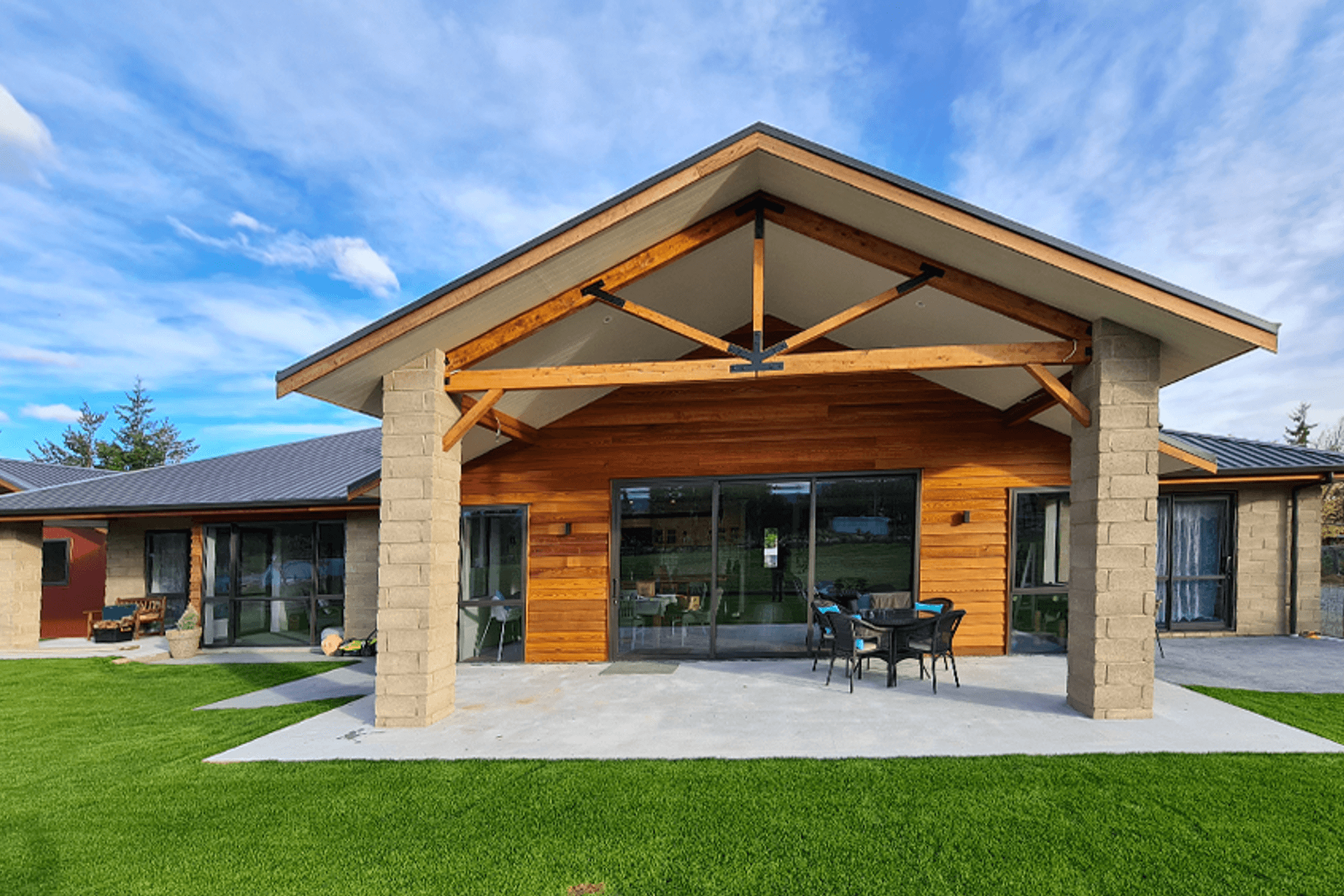

ViBlock: aesthetics that are on-trend

The colours and textures of Kiwibrick reflect the land from which they come. “At the moment we’re selling dark black, white and natural grey. We haven’t had too many sales of earthy tones but there is interest. We’ve only been selling them for six months.”

The response to completed projects has been very positive. The end clients like the aesthetic, while builders are pleased with the material lead times and reduced waste onsite.

Like all the masonry products ViBlock manufactures, Kiwibricks are made of reprocessed aggregates left over from the gold mining and dam construction days in Central Otago. Each brick is named after a waterway which has fed the aggregates. There is a fairly limitless supply, says Jim.

ViBlock: local supply on time

“Being a local manufacturer not reliant on container imports means our operation has not had any supply issues—and we are set up for future growth,” says Jim.

Around 85 per cent of bricks in New Zealand are imported, which has resulted in supply issues as well as quality problems.

Jim says: “Kiwibricks are a great alternative because they are machine-made to a really high-quality threshold before it’s acceptable. Consistent, square and true dimensions mean every brick gets used, whereas with many imported bricks, bricklayers spend time sorting through and discarding those that aren’t useable for construction. There’s a lot of waste. The laying time is therefore quicker for Kiwibricks.”

Viblock: added benefits

Environmentally, Kiwibricks offer many benefits: they’re highly durable; low maintenance; long lasting; and, being produced locally, require very little energy to manufacture and transport to site.

“The only large emitter is the cement—which is used sparingly—and with suppliers committing to being carbon neutral by 2050 and innovations such as carbon curing in development, we believe it will be the best product on the market for generations to come.”

There are many additional benefits to building with Kiwibricks as well, says Jim. “There’s less waste, less time sorting pallets and less supply chain costs. We’re pretty excited about it. It’s just a matter of getting the word out there.”

Find out more about the benefits of specifying Kiwibricks for your next project.