NCC 2025 – A deeper look

The Origins: Lessons from New Zealand’s “Leaky Home Crisis”

In the 1990s and 2000s, New Zealand experienced what became known as the “leaky homes crisis.” Thousands of dwellings were built with wall and roof systems that lacked adequate weatherproofing measures leading to moisture ingress. Rainwater ingress and internal moisture trapped inside wall cavities led to widespread rot, structural failures, mould growth, and health concerns.

The result was a multi-billion-dollar remediation bill and years of litigation. Crucially, the crisis highlighted that simply blocking water at the outside surface is not enough. Buildings need robust, engineered pathways for moisture—whether from rain or from internal condensation—to escape safely.

Australia took note.

Highwood Timber's LVL batten systems give builders a stronger, straighter, and smarter way to create a ventilated cavity behind cladding and underneath roofs without compromising on structural performance, while tackling condensation to improve building health and ease of installation. Highwood battens are built to perform.

The Condensation Problem

Condensation is sometimes called the “silent failure” of buildings. Unlike a roof leak or a cracked pipe, its effects are rarely visible until significant damage has already occurred.

Moisture vapour generated inside homes—showers, cooking, even breathing—can move into wall and ceiling cavities. When it meets cooler surfaces, it condenses into liquid water.

This challenge has become more pronounced in recent years because modern homes are now built to be far more airtight and energy efficient. These upgrades are a positive step: they help households reduce heating and cooling costs, cut carbon emissions, and create more comfortable living environments.

But tighter building envelopes also reduce the amount of uncontrolled airflow that once allowed moisture to escape. Without effective ventilation strategies, internal moisture can accumulate inside wall and roof cavities. Condensed moisture vapour often remains trapped behind external cladding systems.

Over time, this leads to:

- Timber frame decay and structural degradation

- Visible mould growth

- Mould growth and indoor air quality issues

- Degradation of insulation

- Costly, invasive repairs

What NCC 2025 Will Include:

The Australian Building Codes Board (ABCB, 2024) has released a Public Comment Draft outlining the proposed changes for NCC 2025. Some key measures include:

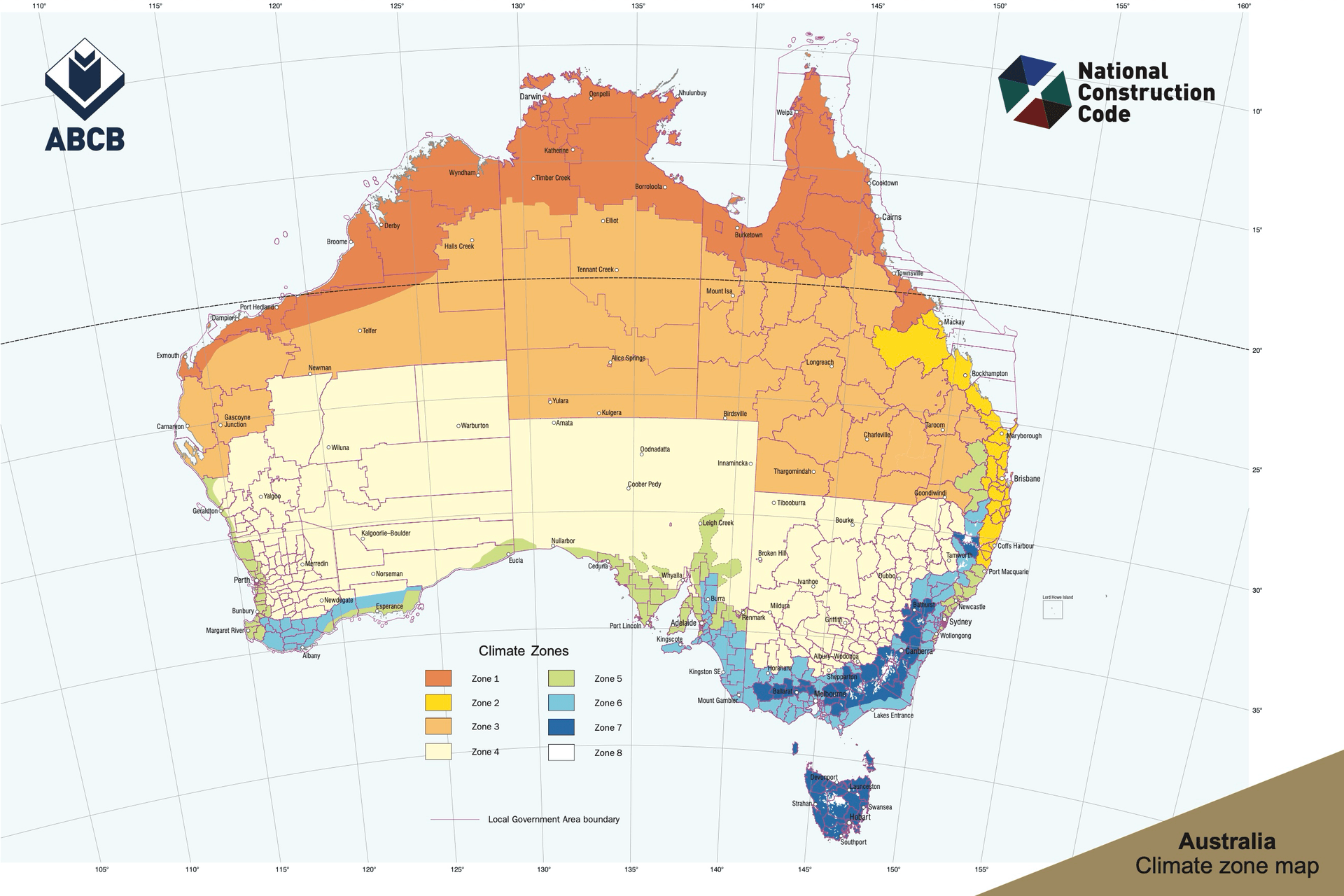

- Drained and ventilated wall cavities in climate zones 6–8, drained and vented cavities behind cladding will be mandatory.

- Membranes and sarking in these systems must meet minimum vapour permeance ratings to allow moisture to diffuse outward.

- Expanded roof space ventilation

- Current ventilation requirements for cold roof spaces (zones 6–8) would extend into zones 4 and 5, recognising that condensation risk exists across a broader range of climate zones.

When Will NCC 2025 come into effect?

- As per Building Ministers’ Meeting: Communiqué on the 22nd of October 2025, NCC 2025 has been scheduled for release on the 1st of February, 2026

- States and Territories can consider adoption from the 1st of May, 2026

Why These Changes Matter

- Protecting health: Mould and dampness are strongly linked with asthma and other respiratory conditions.

- Protecting durability: Moisture damage undermines structural performance and shortens the service life of buildings.

- Avoiding costly failures: The lessons of New Zealand show that remediation costs can dwarf initial savings from improper ventilation.

- Supporting efficiency gains: By addressing condensation risks, the NCC ensures that the benefits of airtight, energy-efficient homes—lower energy bills and reduced emissions—are delivered without unintended side-effects.

- Aligning with best practice: Internationally, drained cavities and vapour-permeable wall systems are already the norm in high-performance construction.

The Bigger Picture

NCC 2025’s condensation provisions represent more than just another layer of compliance. They signal a shift in how we think about building envelopes: not just as weather barriers, but as dynamic systems that must manage air, vapour, and heat together.

Energy efficiency measures have already transformed the way Australian homes perform—making them cheaper to run and more sustainable. With the addition of better moisture management, the next generation of homes can be both energy-smart and moisture-safe.

Because in the end, a dry, ventilated structure is the foundation of a healthy, durable home.

The Highwood Timber Solution: Compliance and Confidence

The upcoming NCC 2025 changes continue to push the industry toward higher performance standards, particularly in moisture control, energy efficiency, and homeowner health. As building envelopes become tighter to meet thermal and energy targets, the risk of condensation and mould growth also increases, making ventilation within wall systems more important than ever.

Highwood Timber’s LVL cavity batten system directly addresses this challenge by enabling consistent airflow and drainage behind cladding systems. Its design aligns perfectly with the NCC’s direction on condensation management, helping builders meet new requirements for vapour-permeable membranes and cavity ventilation in different climate zones. By integrating this system, builders can ensure compliance while improving long-term building health and performance.

Ultimately, solutions like Highwood’s represent the shift the NCC 2025 is driving: building not just for compliance, but for the health and longevity of Australian homes. With greater awareness of building science and access to innovative products, the industry is moving toward homes that perform better, last longer, and support the wellbeing of their occupants.

Highwood Timber battens are in alignment with the proposed NCC condensation management requirements These are the exact battens you want to use on your builds when you are building healthier homes.

Highwood’s HighFlow™ ventilated H3 LVL battens provide a simple, code-ready solution. Available in 70 x 35mm and 50 x 35mm sizes, they combine three critical functions in one product:

- Structural performance – engineered LVL provides strength, consistency, and long-term dimensional stability. LVL battens can span across stud spacing, without additional framing supports required.

- Ventilation and drainage – integrated grooves and bevelled top edge create reliable airflow and water-shedding pathways.

- Code compliance – 2000mm2/ lineal metre of ventilation performance ensures alignment with NCC 2025 condensation provisions.