Thermosash Carbon Reduction Initiatives: Aluminium and Glass Facades leading Embodied Carbon reduction in Sustainable Construction

In 2016 the New Zealand Government signed up to the Paris Agreement and subsequently declared their emission targets. New Zealand’s declared target, set in law under the Climate Change Response (Zero Carbon) Amendment Act 2019, was to be net zero emissions by 2050. The pathway to meet this target has a fast-approaching 2030 objective of 50% reduction in carbon emissions from 2005 levels. However, some who track progress against this target believe that the short-term policies in place will not be sufficient. To achieve the 2030 targets with current policies in place it may be necessary for the country to purchase credits to offset our emissions. While still a positive step forward, NZ would be better served by focusing on carbon reduction across high emitting sectors to achieve genuine emissions reduction.

The construction industry faces increasing scrutiny. As concerns about carbon emissions and environmental sustainability grow, the need for more sustainable building practices becomes increasingly urgent.

Building facades are not merely aesthetic elements of architecture; they have a significant impact on a building's overall sustainability and energy efficiency. Facades, which include exterior walls, windows, and doors, act as the interface between the interior and the exterior environment. Therefore, they play a crucial role in regulating temperature, controlling natural light, and providing protection from the elements. Aluminium and glass are two widely used materials in modern building facades, prized for their versatility, durability, and aesthetic appeal. However, their production and usage can be associated with significant carbon emissions.

The answer often lies in moving to modern material manufacturing processes or selecting new materials altogether that have a smaller carbon footprint. Regretfully, changing processes in almost any industry often comes with an associated increased cost as producers move from suppliers that have built efficiency in their production processes over many previous years, to ones that are utilising new methods, new machinery, and new technologies. Increased costs are almost always inevitable. The timing for our country’s net reduction and zero carbon goals, imposed on New Zealand industries by the commitment to the Paris Agreement, come at a time when New Zealand already is known as one of the more expensive places to build. Further, with the additional post-Covid 19 supply chain and material cost increases, and the increased costs associated with the recently imposed H1 code to increase building thermal efficiencies – it is an unfortunate time to be adding yet more cost to the building industry.

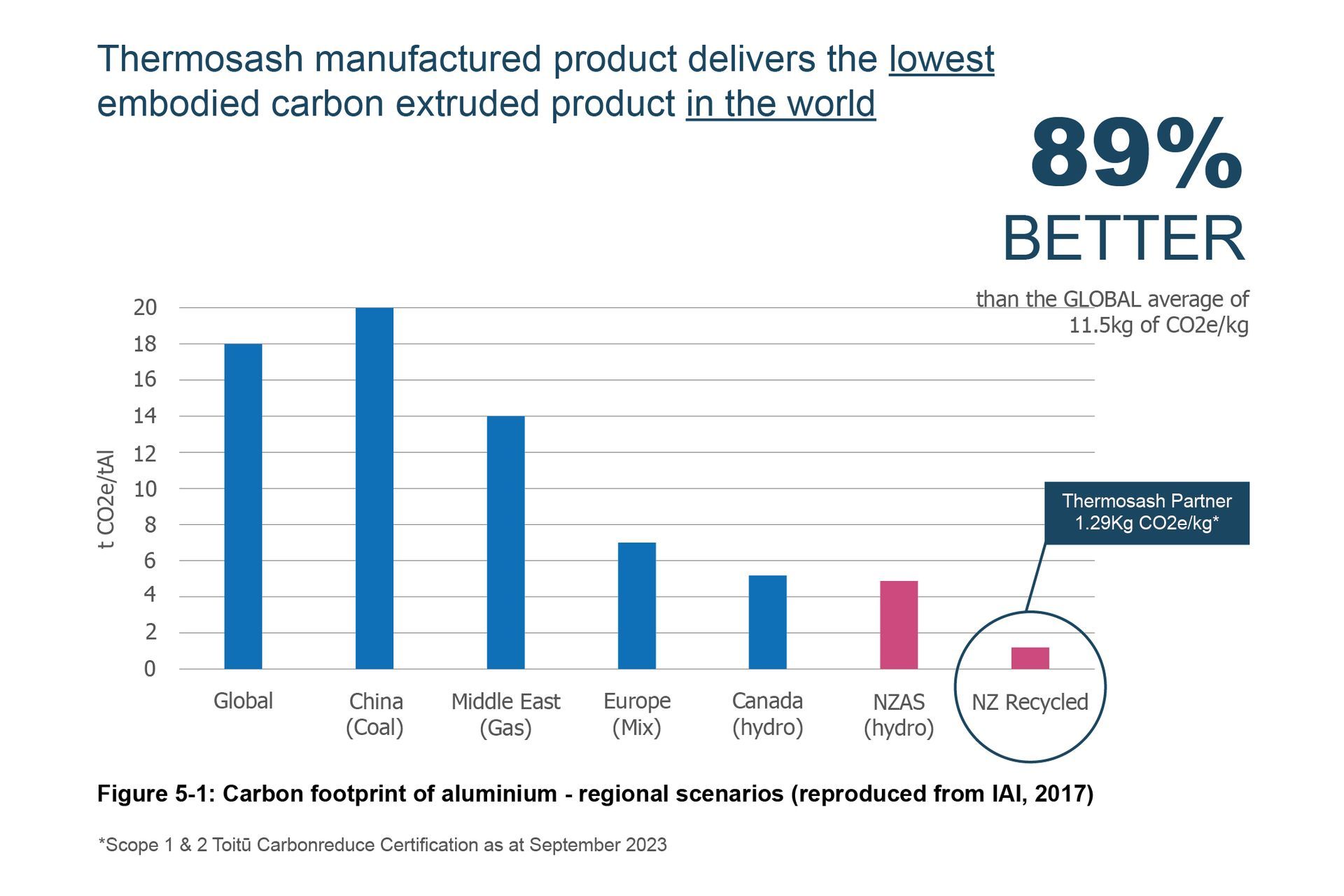

The building industry requires glass and aluminium in tremendous volumes, both of which are large contributors to a building’s embodied carbon. Aluminium in particular has had a reputation for being a ‘dirty’ product, with approximately 55% of world production occurring in China where less than 30% of energy produced is renewable and the majority is generated by burning coal. However, some industries have been working on the challenge of lowering embodied carbon in our built environment for many years.

Thermosash have developed internal systems and software and have partnered with suppliers to provide its customers more beneficial improvements to building facades in New Zealand than any other façade company. Reduction of embodied carbon is one of the most significant benefits.

Thermosash has a unique worldwide position in that it’s New Zealand extruded aluminium frames are produced using a majority percentage of recycled aluminium content that uses ~5% of the energy required to produce raw aluminium. Coupled with our connection to a renewable energy power grid - our product offering is now considered to have the lowest embodied carbon for extruded aluminium in the world. A Rio Tinto report produced indicated that China has embodied carbon rates of between 18-20 kgs/Co2e/kg for their aluminium, with Europe and Australia offering low carbon and ultra-low carbon alternatives to the construction industry – Thermosash’s average is 1.29kg/CO2e/kg (Scope 1 & 2) up to 41% lower than the lowest internationally offered alternative.

Coupling the low embodied extruded carbon with Low-Carbon Glass adds further improved value to a project and should be considered complementary to the building’s operational carbon emissions reduction achieved through design and glass selection. With large format glass facades, we are able to reduce the energy required to operate the building over its expected life. This is achieved through the high performance of the glass which reduces heat loads, lowers reliance on high energy draw air conditioning, and minimises heat loss through the highly insulated glass and non-vision unitised façade panels, and importantly, our facades have an almost zero air leakage façade design (tested to be upwards to 10x better performing than NZ Building Standards) meaning that the air that is conditioned inside a Thermosash building will not be lost to façade air leakage and the building will be better performing and with lower operating costs for owners and tenants.

Our customers who are seeking carbon reduction or zero targets, as well as their customers and shareholders, will see the environmental as well as financial benefit of incorporating a Thermosash façade system on their buildings - mitigating the greenwashing of offsets and potential for an additional 50+ years of carbon reduced costs on their building assets that were specified with the lowest embodied carbon products of the time.

We are seeing the early adopters already recognising that a building built today with low embodied carbon and low operational carbon will have a building substantially more compliant with 2030 and 2050 government targets. Reducing carbon emissions in facades is not just a responsibility but also an opportunity for the construction industry to lead in the fight against climate change, one building at a time.