Opening the door to new pivot technology

Written by

11 April 2021

•

4 min read

Not long ago, if you’d specified a two-metre-wide, 300kg marble pivot door to welcome your guests into your home, your architect or designer would have politely told you the bad news: it simply wasn’t possible to create doors of that weight and size.

Homeowners were restricted to the traditional model of pivot door, most often associated with malls and hospitals, which has its limitations around design and materiality due to the traditional floor-mounted pivot system.

But the benefits of pivot doors are hard to replicate in hinged doors; they offer an unparalleled simplicity in aesthetic, along with ease of use.

Unsurprising then, that a Dutch hardware company decided that it was time to overcome these limitations.

Bellevue Architectural’s Barrie Midler says the FritsJurgens pivot door system answered the call for more flexibility in design, with a completely concealed mechanism that easily accommodates a pivot door weighing up to 500kg.

“When we’ve talked to architects and designers in the past they’ve said to us: ‘We can’t really design the door we want’. What we’re seeing now is lots of FritsJurgens systems being specified where pivoting systems couldn’t have been used in the past.”

Pivot doors no longer restricted by size or weight

Barrie says there’s been a huge uptake in the residential housing market because homeowners expect their penthouse, apartment or home to feature a front door that looks “absolutely spectacular”.

For designers and architects, it means they are now able to specify doors entirely cut from stone or fabricated from metal. It also means doors are no longer restricted to conventional shapes, heights and weights.

“In the past you had to sacrifice design for practicality. For example, the door could only be 1.4m–1.5m wide.”

Architects and designers are now specifying pivot doors with the concealed system for widths upwards of 2.5m and larger, in a range of materials from steel to stone or hardwood.

“From an engineering perspective, the people that make and fit the doors are thrilled because when an architect specifies a door and says: ‘We want this...’; they no longer have to turn around and say they can’t do it.”

And, unlike standard domestic pivot door systems, the door mechanism has been tested to a impressive one million cycles and is guaranteed to perform for 10 years.

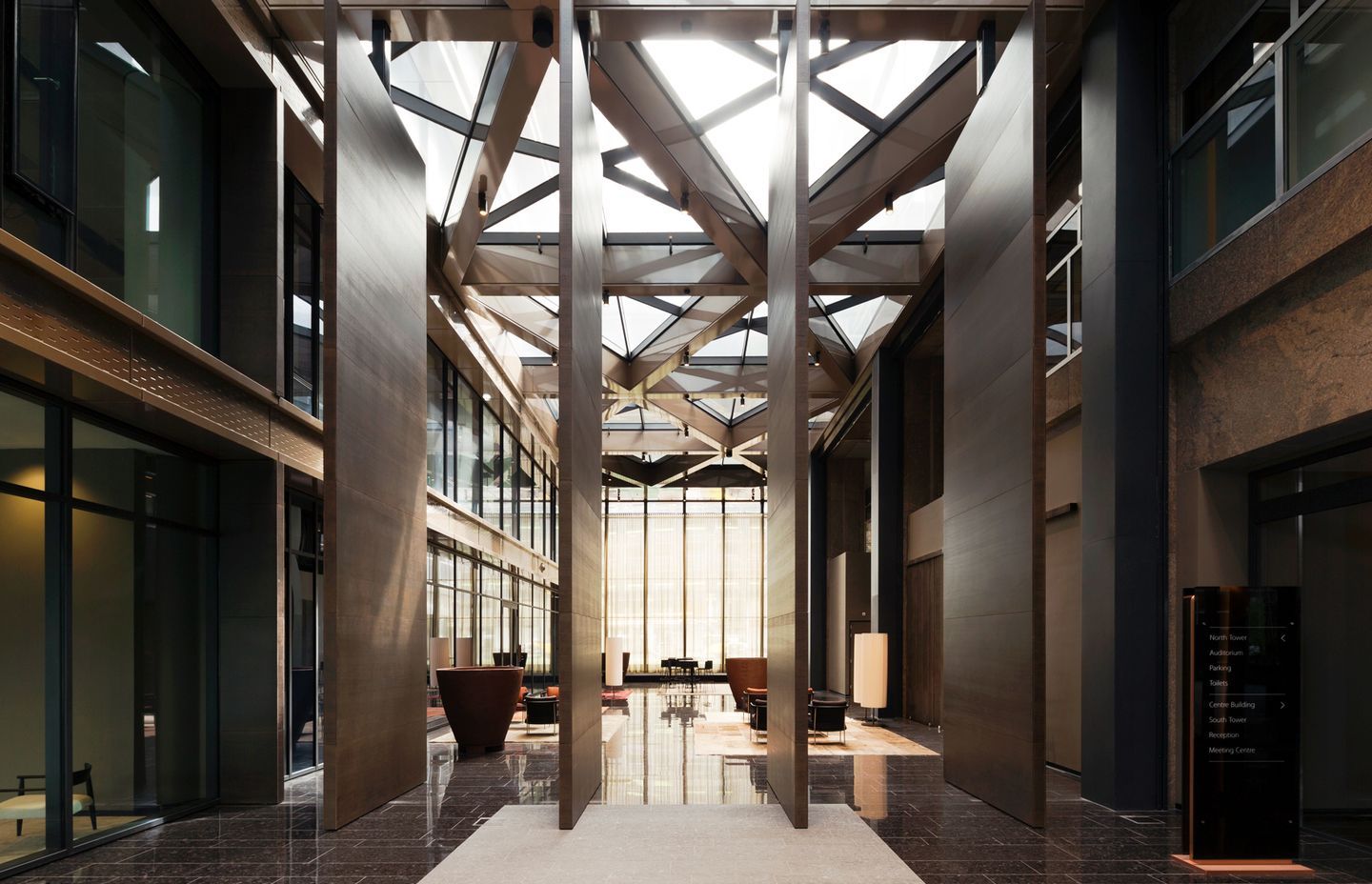

The longevity of the system is due to its roots as a commercial product where solutions need to factor in high foot traffic and activity. Those commercial spaces are also taking advantage of the newfound design freedom the concealed pivot system offers.

In Newmarket, Auckland, Westfield Shopping Centre has used the FritsJurgens system in its high-end, high-traffic environment. Similarly, the system has been incorporated into the fit-outs of Christchurch Library, Hotel Britomart and construction firm Mansons’ offices, to achieve bespoke solutions that cater for continuous use.

Pivot doors now with seamless floors

Apart from weight and size restrictions, another reason pivot doors were only ever rarely used was the unsightly floor plates covering the pivot mechanism.

The FritsJurgens system is entirely concealed inside the door, so there is no need for the pivoting mechanism to be sited in the floor.

“Beautiful floors are an important part of any interior design scheme and it has always been a bone of contention with designers to destroy the look and feel of the floor with a floor plate, which is required for a traditional pivot door,” says Barrie.

From an aesthetic perspective, the concealed mechanism of the FritsJurgens system means designers and architects can now design floors that are seamless, alongside pivot doors without design limitations.

From a practical perspective, the concealed pivot system drastically reduces installation time as, unlike traditional systems, holes don’t have to be cut into concrete slabs to house the pivot mechanism.

Both practical and aesthetic improvements mean the sky’s the limit for designing high-impact doors in interesting materials.

“We're seeing doors become larger, wider and significantly heavier and that’s coming from the fact that we’ve taken design restrictions away from architects’ and designers’ creative minds.”

Learn more about innovative pivot door systems for your next project.