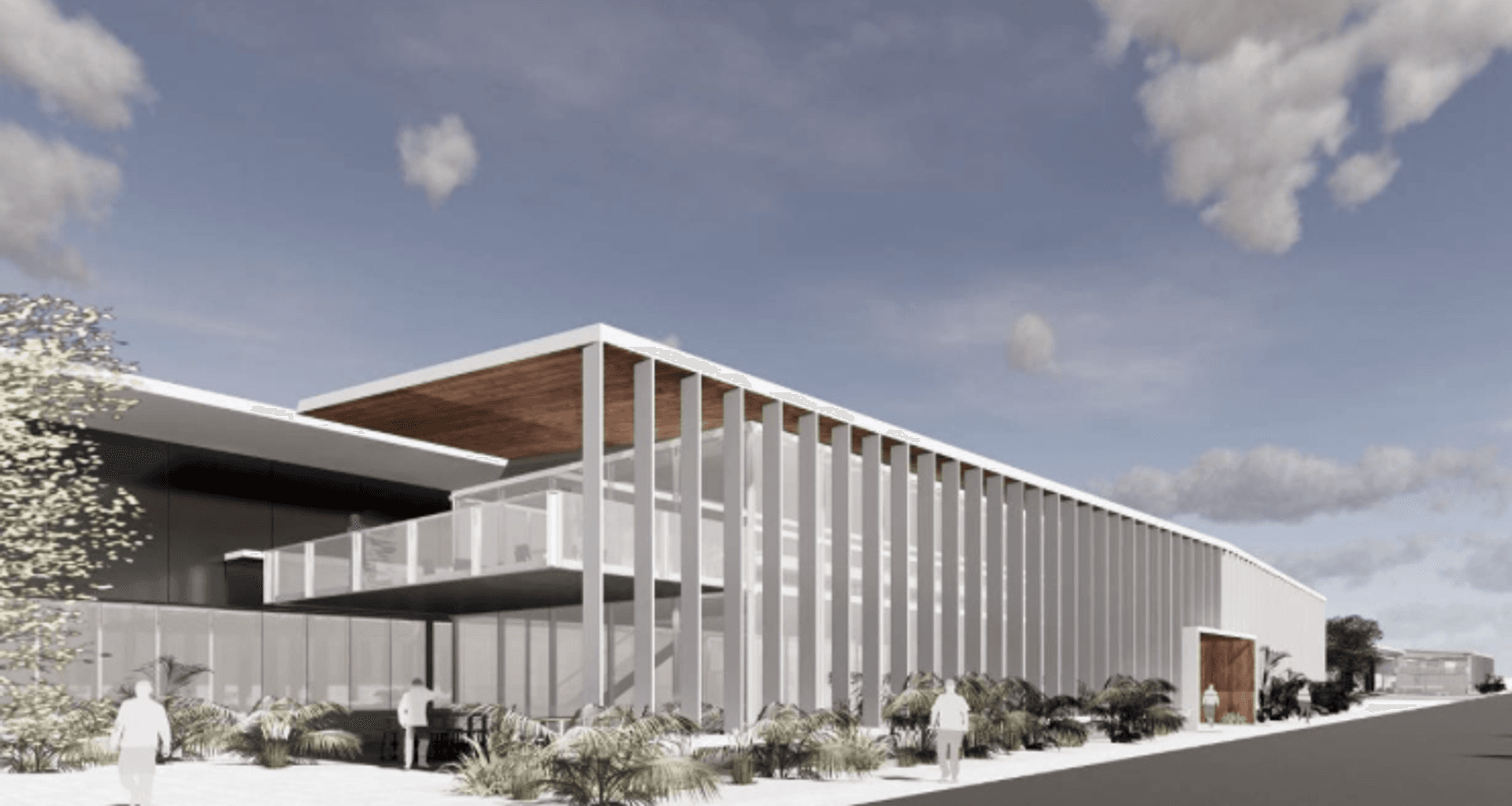

Quality and quantity on massive APL building

Foster Construction are used to very large construction projects after successfully completing the new Visy Board Packaging house in 2018 - a 32,000m² facility which at the time broke the record for largest footprint in the Waikato.

“This build is far bigger with a floor area about a third larger again than the Visy Board building,” says Adam Findlay, Construction Manager for the Foster Group.

With concrete a huge factor in the construction process for a building of this size, Adam says they had no hesitation in working with Firth again. “They know what they’re doing and are doing an excellent job for us.”

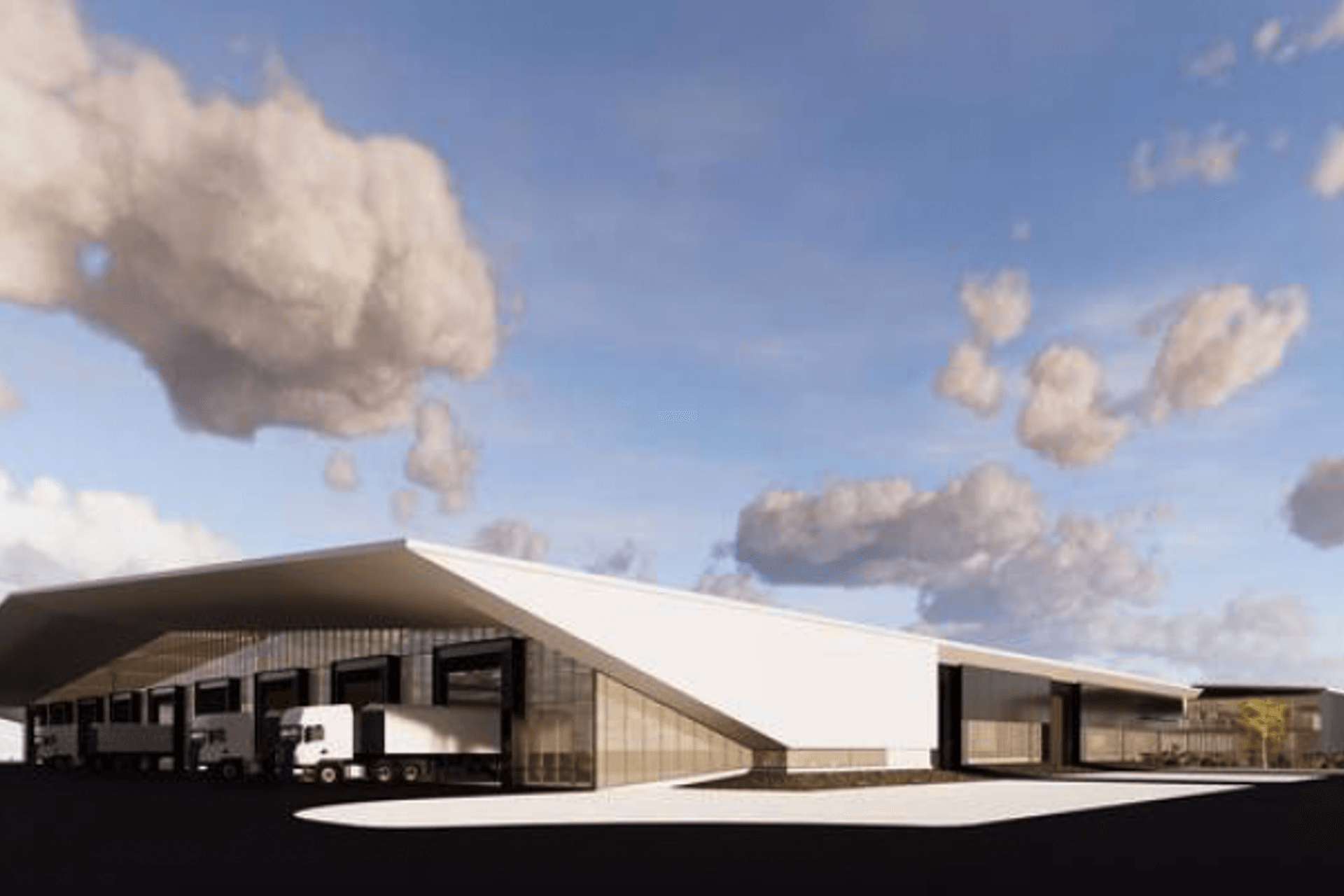

The structure is about 95% complete with the floor about half way through being laid. Once again the Foster team has built the roof before pouring the slab foundations. “The height of the roof and size of the building does dictate our ability to work this way,” says Adam. “The APL building is certainly of a scale for this construction method. With the roof on before we pour the concrete we can control the environment. It means we are not affected by the weather and it keeps the schedule on track. We also get a far better finish and product. Wind and rain is the killer of concrete."

“The largest pour to date on site has been for the post tension section of the foundation,” adds Adam. “That pour was pretty big at 617m3 but we now have a philosophy of undertaking smaller, more manageable pours but more often. We’re trying to keep the pours around the 200-250m³ mark two to three times a week because we feel without the pressure of a massive pour of 20 hours straight we can do smaller sections well and have a better quality product and finish. Also it takes the pressure off our team. The last thing we want is them burning out.”

“The smaller pours do mean we can control quality a lot better which means a better product,” says Rob Mulder, Area Operations Manager (Waikato) for Firth. Quality is certainly the operative word for this project. Rob says that Firth has two staff on site for every pour, testing and ensuring the product is of the highest standard. “Our Te Rapa site is managing most of the concrete supply which is going to be about 13,000m³ by the time we are done. We have called in trucks from Firth Te Awamutu, Mount Maunganui and Auckland at times at times.” With a 35-40 minute travel time Rob says he’s proud of his team. “It's a big job and our team is doing a great job.”

On a project of this size Adam says that sure and steady wins the race. “It’s certainly a marathon - not a sprint - and we are grateful for Firth’s help once again.”

APL expects to move part of its operation in by 2020 with the remainder following within five years.

Once the APL building is complete, the balance of the industrial park area will eventually become available for other industries to set up shop. The second stage will come in 2021 and the third and final stage of the development of the park will be available in 2024.

Customer: Foster Construction

Sub Contractor: Conset Construction

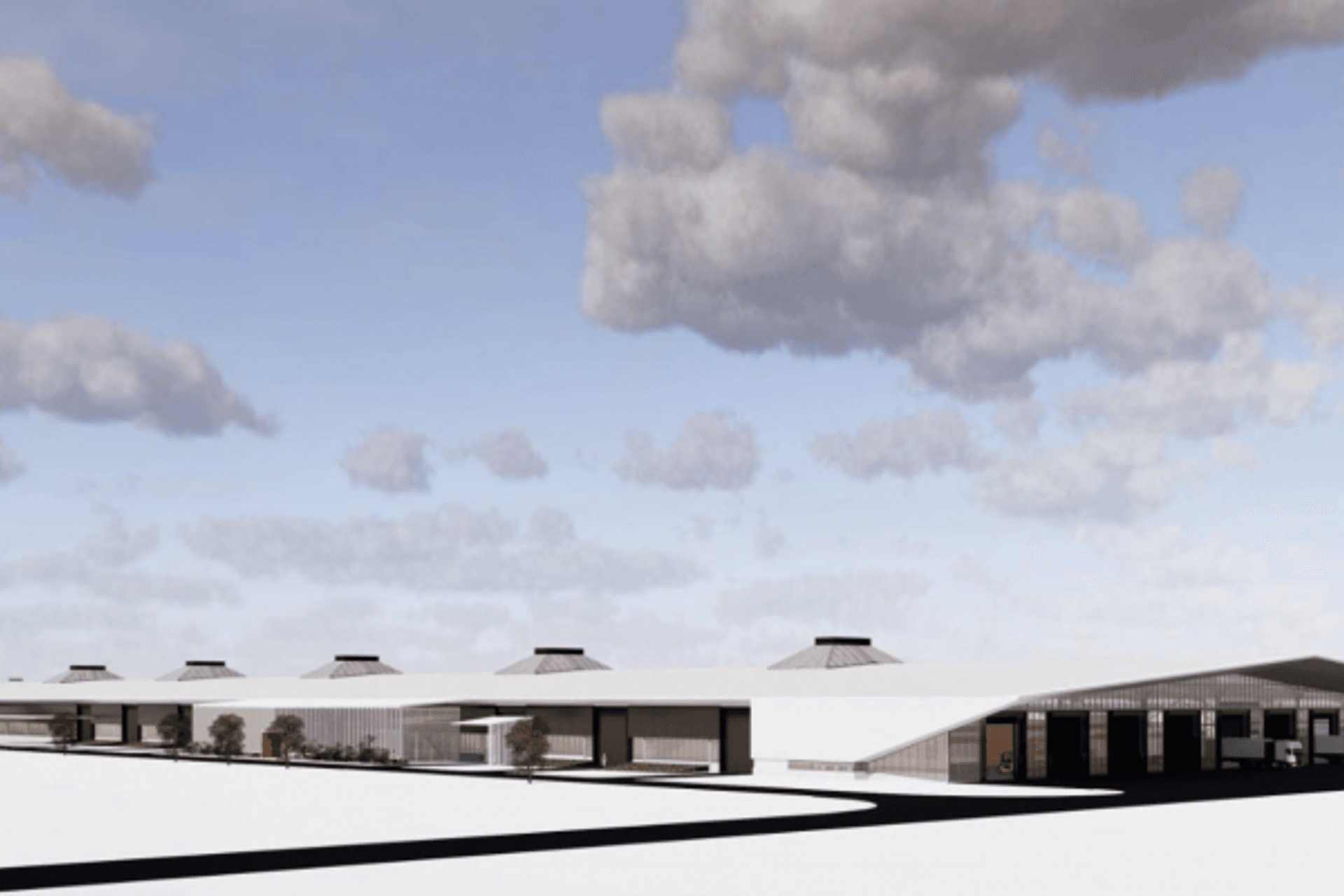

Project: Architectural Profiles Ltd - new facility

Location: Hautapu, Cambridge

Product: Firth Certified® Concrete