Rejuvenate vinyl floors in your commercial space

Written by

23 April 2023

•

4 min read

In Europe, the environmental impact of throwing out old PVC vinyl floors has long been recognised. So much so that a permit is required in many European countries to discard worn out vinyl.

In response to the move to rejuvenation rather than replacement, a product called Bona Resilient was developed by Swedish company Bona that would extend the life of existing linoleum, PVC, vinyl, PU rubber and LVT floors. The solution involves rejuvenating and coating existing flooring to create a new wear layer, and the colour or design can be updated in the process.

Complete Flooring has the exclusive licence for Bona Resilience in New Zealand and director Jaron Cook says there are multiple benefits to rejuvenating rather than replacing.

“One of the biggest draw cards to the product is that PVC vinyl that's already installed stays on site and doesn't have to be uplifted and put into a landfill - that’s a huge benefit to the environment”

In the past, polish was often used to rejuvenate vinyl, but it isn't great for the environment and doesn’t give the floor a new wear layer with longevity.

A vinyl might have a 10-year lifespan in a commercial setting, but with Bona Resilient you can continue to coat that vinyl (as long as it's adhered or installed properly) every five or 10 years or whenever you need to change the colour or design.

“A second benefit is that the time it takes to pull up commercial vinyl, prepare the substrate and install new vinyl is significantly larger than the time that it can take to repair, clean and recoat with Bona Resilient,” says Cook. “This is positive in time-sensitive projects like kindergartens, schools, dairy factories, and spaces where you're only given a small window to undertake the project.”

In addition, because you're coating an existing product, there are very few uncertainties or unknowns, as opposed to when you’re replacing vinyl - meaning the client has certainty around time frames.

“If you’re removing and replacing vinyl, once the uplifting has begun, you can run into a lot of unforeseen issues, especially in a small time frame. No one wants to get a call on the weekend about extending the job for a couple of days.”

How it works

Coating with Bona Resilient gives vinyl another wear layer and the ability to change colours or create a new design.

The process begins with a site assessment to ensure the existing vinyl is installed correctly.

“The process is to do any vinyl repairs you require and this can be done with any colour and any piece of vinyl - it can be cut out and patched. It gives you plenty of options if walls have been moved or spaces have been changed. We can patch it, repair any welds, and repair mitre work.”

Once the vinyl is in a state ready for rejuvenation, a polish remover is applied to remove any contaminants and/or polishes that are on the vinyl, including any factory polishes or added polishes. This is then sanded with diamond pads..

“From there you move on to removing the polish with water and a power scrubber and repeating that process until all the polish remover and polish is removed.”

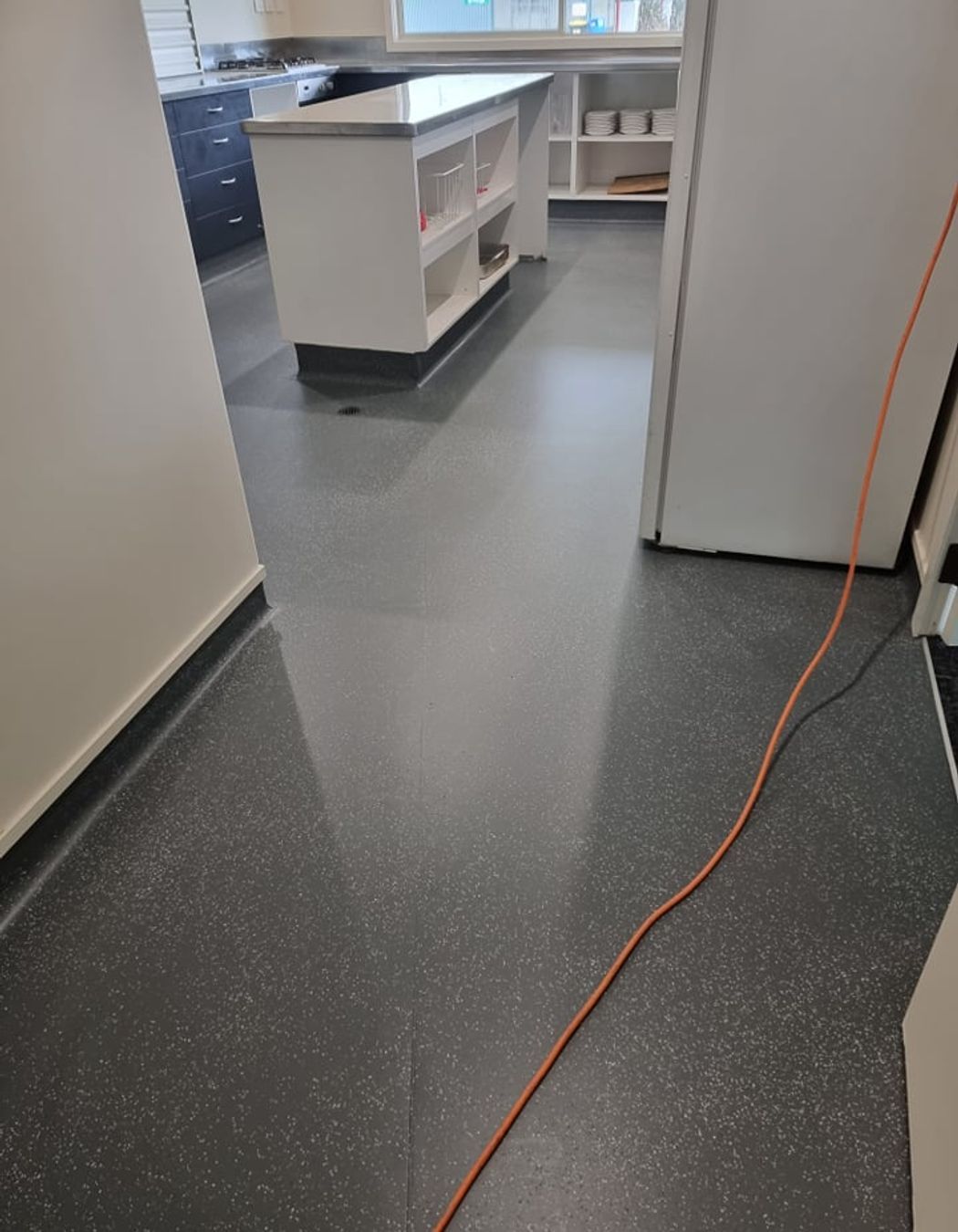

Once it’s clean and dry, two coats of your desired colour or graphic design is applied, and you can choose from any paint colour that can be purchased from paint stores, and if you want the classic vinyl “flakes”, those are added in the second coat.

Finally two to three clear coats of Bona Resilient are added, giving a workable, wearable layer that can be added to a cleaning regime, or renewal regime long-term, depending on the use of that space.

“For a high-use space, we might do a cleaning regime where we come back once every year or two years to clean that surface and add another clear coat.”

The durability and low VOC of the coating makes it an excellent choice in commercial spaces such as childcare, or care homes with immune-compromised people, as well as in dairy factories and in the education sector.

Design customisation

In addition to its longevity, durability and environmental benefits, the Bona Resilient solution has a high level of customisability, says Cook.

“Being a paintable product, we can add designs, or customised stencilling. We can print off or get customers' branding for entrance ways and it can be stuck on prior to the paint or clear coats going on and be encapsulated within the coating system.”

Learn more about floor rejuvenation solutions Waikato flooring experts Complete Flooring.