Revolutionising the civil construction industry with Brazil ao Cubo and Trimble technology

The company grew 200% in 2020, which was exceptionally impressive because it was during a very difficult economic time period. Ricardo believes the growth is due to his employees.

“Brasil ao Cubo is not only made up of engineers but it is also made up of employees in the field who worked hard to understand how every single structural detail would work together to bring projects to life,” says Ricardo.

We sit down with Cáudia Mateus, Co-Founder and Architecture Manager, and Matheus Dubkowski, Architect, to talk about SketchUp’s role in all of their projects.

How did you get started with SketchUp?

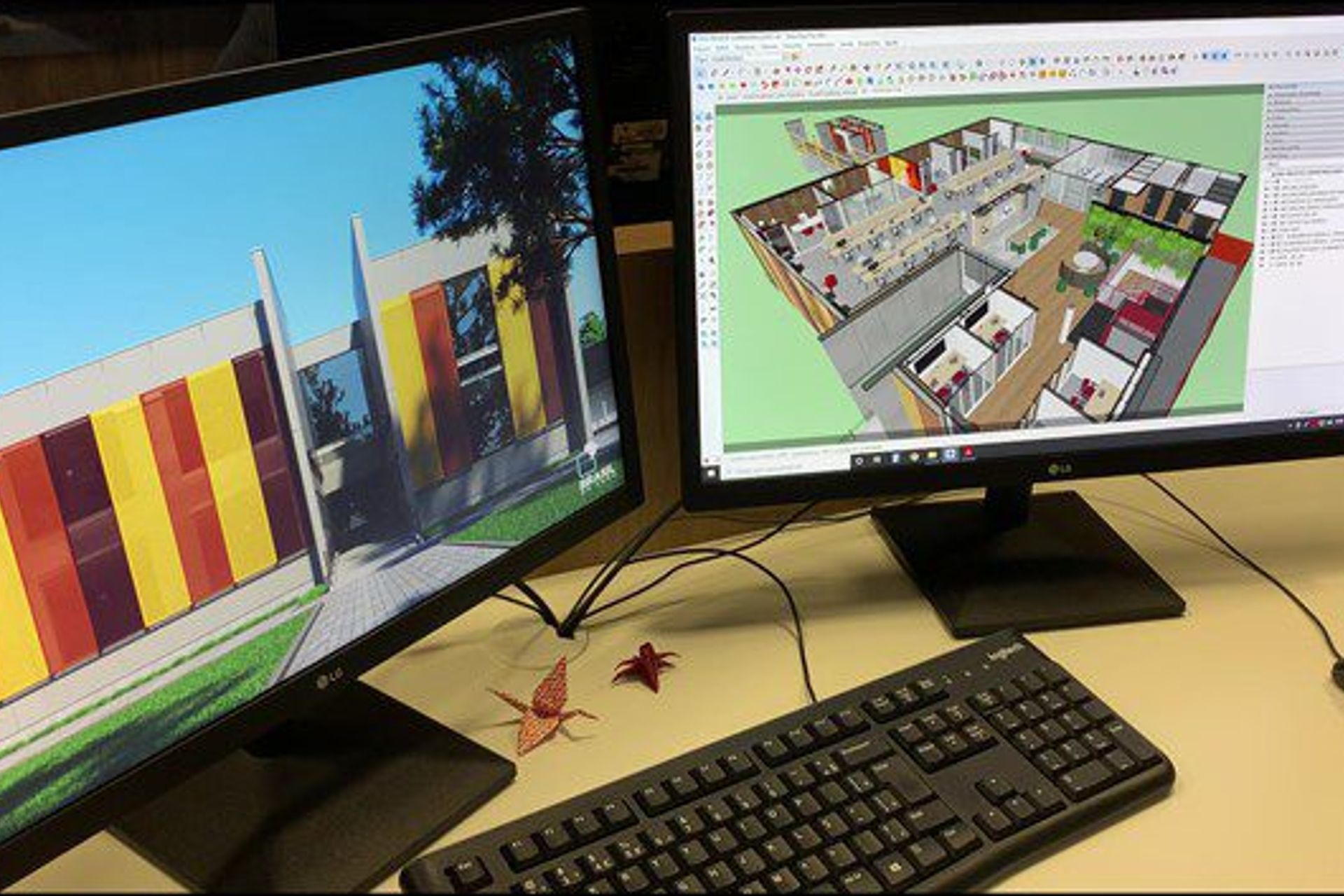

Cáudia: I started using SketchUp in 2009 at my father’s company, EMETU. At Brasil ao Cubo, we start every project in SketchUp. Our CEO, Ricardo, believes that SketchUp means “to facilitate”. The first Brasil ao Cubo projects were all detailed in SketchUp. I still have all the old projects saved! As you can tell, we are very passionate about the program!

In the context of modular, off-site, industrial design, what is the role of architecture? And, where does SketchUp help?

Cáudia: At its inception, Ricardo had the idea that Brasil ao Cubo would sell standardized, modular commercial spaces. He wanted to have a catalog of standard options where people could pick and choose. I was brought on board because I thought a little differently. I believe all projects should have an identity. I don’t like the idea of replicating designs — I want to be able to switch things up with each project and add in custom elements that set it apart from the rest. Because for me, architecture should be personalized.

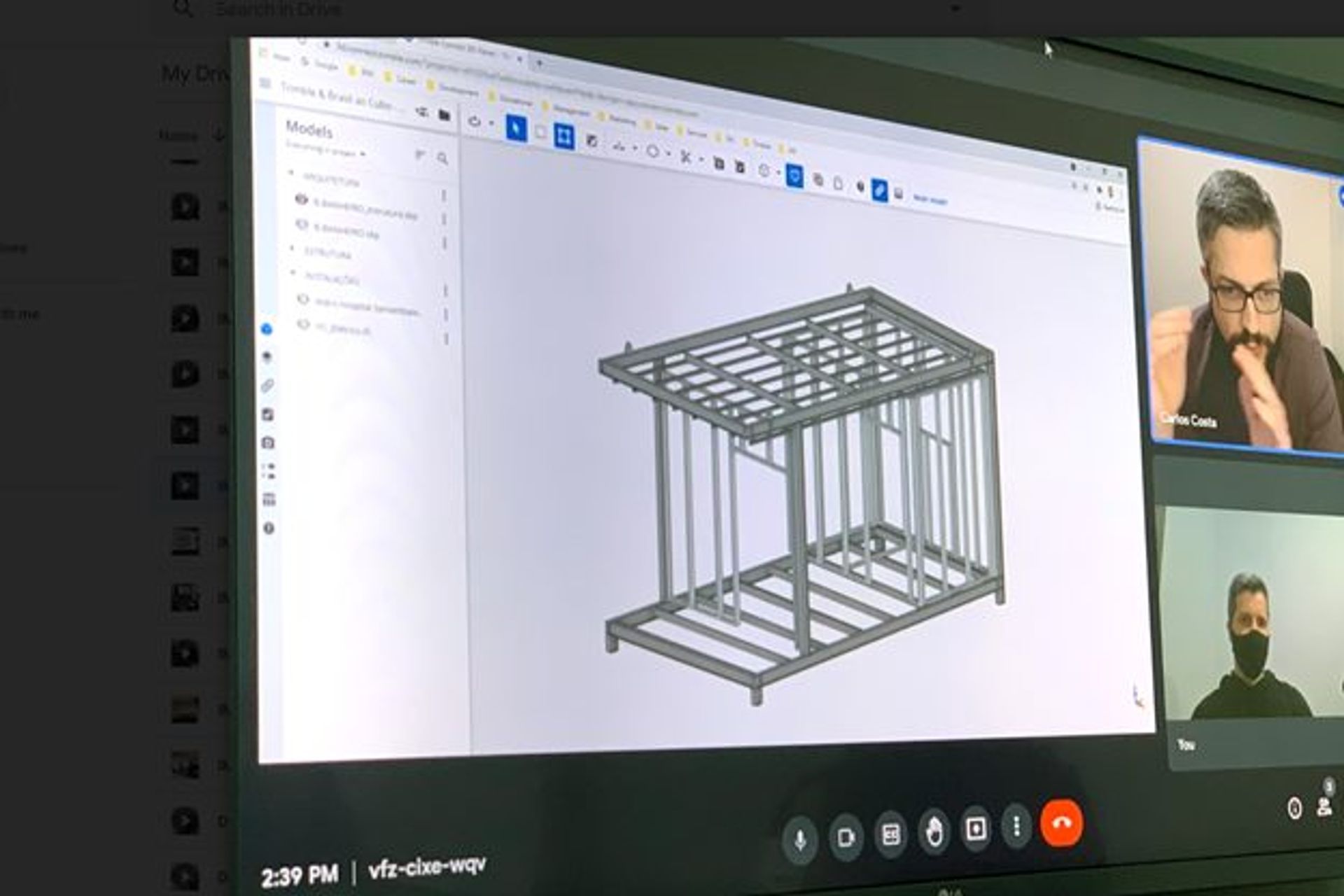

So with my background and Ricardo’s vision, we’ve been able to merge our ideas and form what Brasil ao Cubo is today — a modular construction company with a strong emphasis on custom architecture for each project. When we talk about standards, we are talking about standard modular patterns that can be transported easily. We take those patterns and build and develop them in SketchUp. We then bring the designs to life with renders, which help the client understand what the space will look like. This is typically the client’s first experience with modular construction, so it’s critical that we show them how it works and get their buy-in on the design. In all of our presentations, we include both the assembly scheme and modular scheme, so it makes a great impression when you see it all together. We want our clients to understand that they are not buying just a standardized design but that it’s truly a piece of architecture that will make a difference.

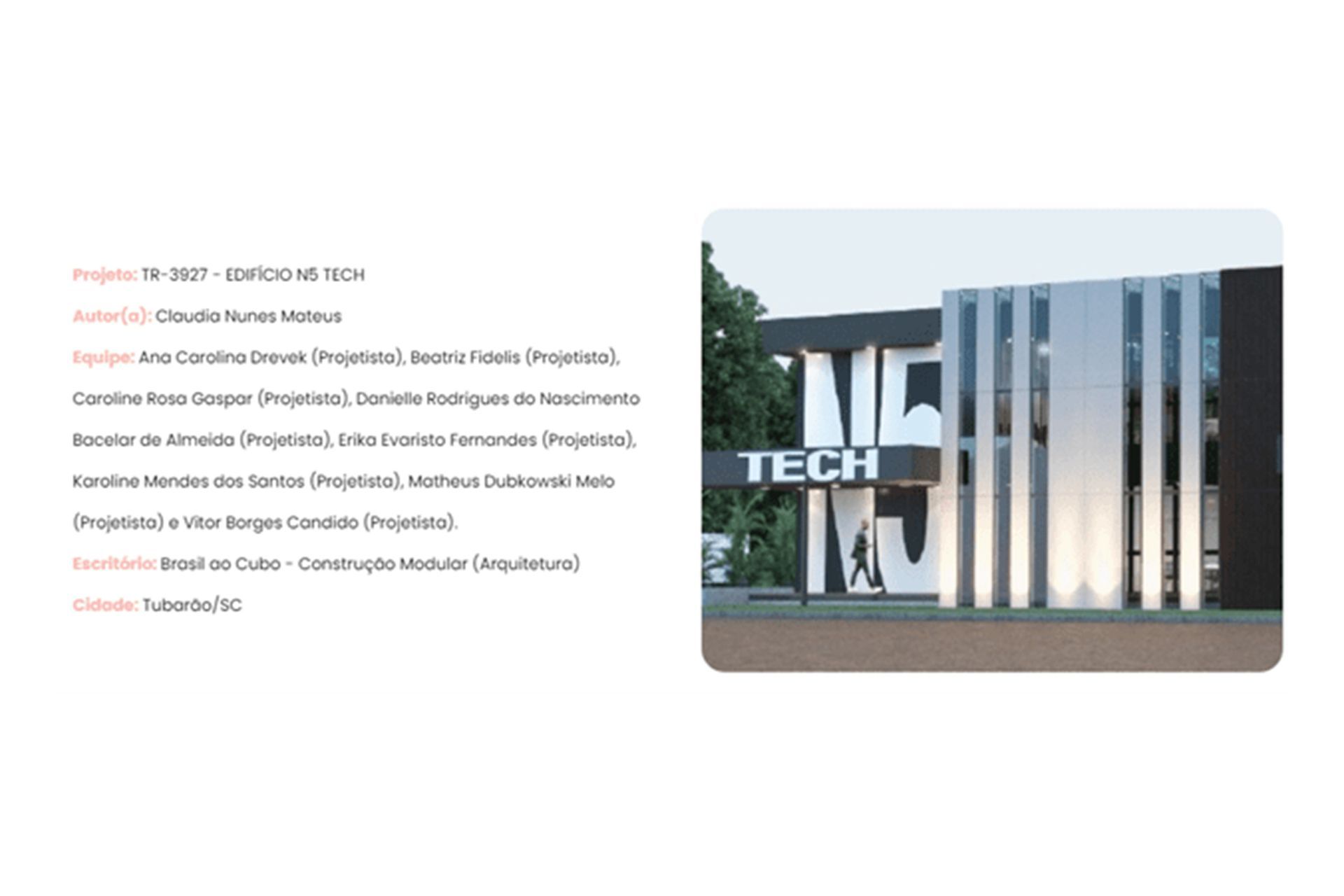

Learn more about this project here.

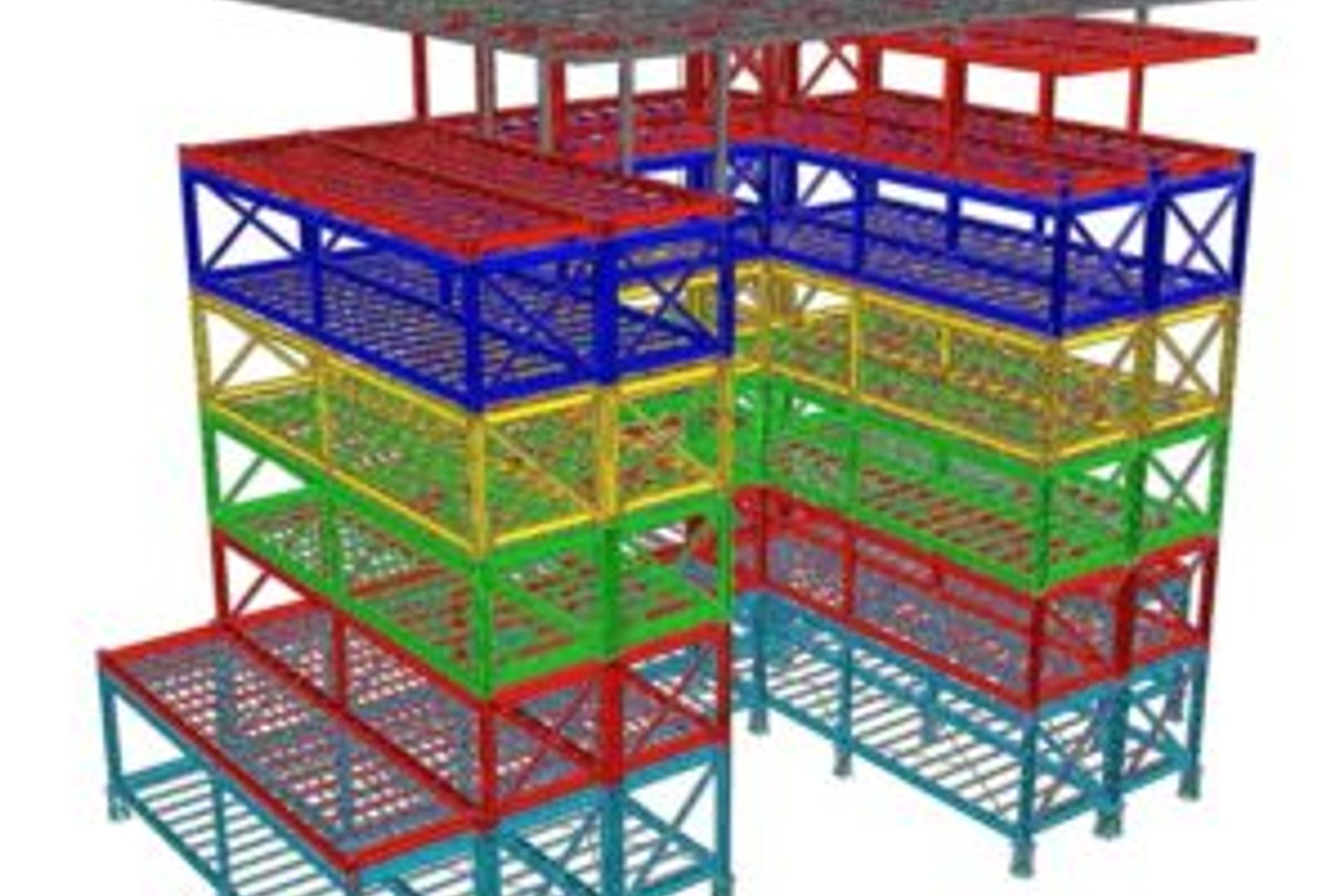

Another memorable project was also one of our most challenging projects, the Edifício Level. I believe this project was the beginning of a revolution in construction. We had to build eight floors in a modular way, different from anything anyone has ever done in this region.

A partner office initiated the architecture work and we took the design ideas and built it up even bigger. Since this was a first for everyone involved in the project, we had a lot of work to do to get everyone on the same page. We had to build the entire building in SketchUp and develop animations showing how materials would move in and out. We had a ton of positive feedback with the design and were able to complete this building in just 100 days.

How do you describe your design process?

Cáudia: At the end of the day, we have to deliver the project to the construction site. Luckily, both SketchUp and Brasil ao Cubo are dynamic and can adjust to edits, dimensions, and client requirements.

Some elements we have to keep in mind are that the materials have to be prebuilt and delivered to the final site in an efficient way. Our goal is to have our process four times faster than the conventional process.

With that, we start our design in SketchUp. We pull in all of our construction information so that the model is an accurate representation of the building. From there, we use LayOut to create different views and plans with dimensions. With SketchUp and LayOut, we’re able to move project information forward in a more efficient way using visuals laid on top of dimensions.

What does the future look like for the modular construction industry and what role will technology play?

Cáudia: For Brasil ao Cubo, technology will continue to play an important role in our workflow, specifically displaying project information through SketchUp. We’ve already started evolving our workflow with SketchUp so it’s better integrated into our process. For example, I don’t need to print anything to see what a coating will look like, I can just visualize the coating within the space in 3D.

Another trend we are looking at is robotization. We’d love to industrialize the construction process for these modular spaces. For example, you enter the construction “dealership” and you say, “Hey, I want to upgrade my 2026 home with the 2036 model.” From there, we’d deliver it to you in a few days and you can start living in it. That’s the vision of the future!

What did you think of the Trimble Orbiter Program?

Side note: The Trimble Orbiter Program is a program the Latin American customer success team developed to help companies evolve their workflows using the larger Trimble ecosystem.

Cáudia & Matheus: It was a fantastic program. We were able to ask questions and figure out how to take our work in SketchUp and other Trimble products to the next level. We discovered things we were missing, such as how IFC works, how to coordinate projects using Trimble Connect, and how to make an integration between SketchUp and Tekla. These new workflow insights made it possible for Brasil ao Cubo to support OpenBIM. Being able to meet with the Trimble team and ask questions was invaluable. It was like a personalized training. You truly immersed us into the Trimble universe and increased our confidence in your products. We are always looking for ways to improve and innovate, and I believe that Trimble allows us to do that. We are at the forefront of evolving the Brazilian civil construction industry, and your products help us do that.

What does the future look like for you and Brasil ao Cubo?

Matheus: First, I would like to thank you all for investing all of your time and energy in our company.

“I literally got goosebumps seeing how all of the different technology from Trimble connected and how we could leverage it at Brasil ao Cubo.”

On future projects, I know now that there are tools to do both basic tasks and more advanced tasks, easily and quickly. I don’t have to kill myself trying to find workarounds or solutions, they are right here with Trimble. I just need to define my problem at the beginning and decide how I want to deliver that information. The future of SketchUp and Brasil ao Cubo looks good.

Cláudia: Years from now when we look back, I think we will realize we’ve both helped each other. You all helped us realize the endless possibilities with Trimble and SketchUp, and I think we can help others understand how SketchUp truly is BIM.

“We realized during this session that we can work within SketchUp to accomplish all of our project goals — everything is integrated, from BIM workflows to IFC compatibility.”

We’re also excited to see how Brasil ao Cubo will grow. On July 1st, 2021, we were the winners of the AsBEA Saint Gobain Brazil Award in the Professional Category for a commercial project. So we’re happy to see that we’re already revolutionizing the construction market. I can’t wait to see what else the future holds!