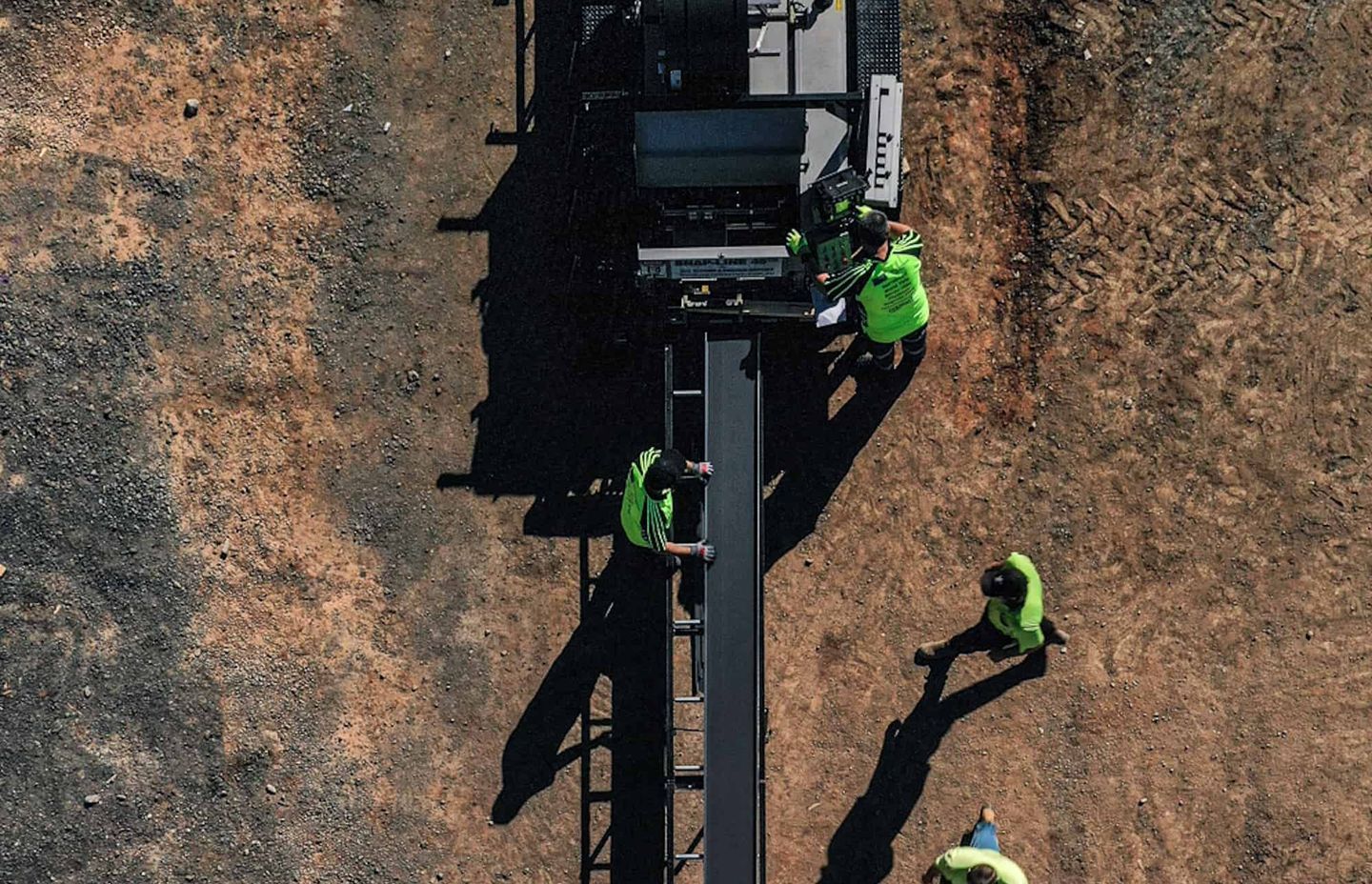

Snap-Line 45® Roll-On Site Machine

Snap-line 45 is an architecturally inspired modern metal roof and wall cladding suitable for all residential and commercial applications. And now our new Snap-line 45 roll onsite machine gives you even more flexibility in your design and engineering approach.

You’ll love Snap-line 45’s ability to handle nearly all pitch ranges down to 1° and its structural self-supporting profile does not require continuous backing (depending on span limitations and material choices).

It’s one of the strongest architectural profiles on the market with sheet thicknesses ranging from 0.55mm to 0.7mm. SNAP-LINE 45® meets or exceeds the required standards: AS1562.1-1992.

And the high water carrying capacity of the 45mm high ribs and wide pans ensure that Snap-line 45 deals with heavy downpour events with ease.

Deep ribs, wide pans and an expansive palette of material choices and colours including Colorbond, Zincalume, Zinc, Copper, Aluminium and COR-TEN offer the designer a vast array of creative design options.

Roll Onsite: Advantages

Our roll onsite machine allows us to roll Snap-line 45 onsite. This delivers a number of additional benefits that designers and engineers will want to take advantage of.

Long Length Sheets

We can roll out exceptionally long sheets in seamless runs. Our recent Barrengarry project involved the creation of 24.5metre long seamless sheets but effectively sheet lengths are only limited by the length of a roll of steel.

Being able to do this eliminates the challenge of transport difficulties and eliminates the possibility of damage to over-long sheets in transit. Rolling onsite also eliminates any additional freight costs incurred in transporting over-sized items.

Long length sheets also eliminate length lap joins for a slick seamless cladding profile as well as increasing the waterproofing performance. Fewer lap joins also produces labour cost savings and speeds up installation time.

Less Wastage

Roll onsite capability means sheets are cut to the exact length required as needed. There’s no need to order extra lengths to allow for wastage or estimation inaccuracies.

Cut lists can be adjusted on the spot. Rolling onsite also eliminates expensive reordering and transport charges where there are inaccuracies in pre-ordered and supplied cladding.

This is great for the budget and the zero wastage is a real plus for the environment. This is an additional bonus when dealing with projects that require greater environmental protection oversight.

Reduced Storage Requirements

Roll onsite capability eliminates the need for unloading trucks, double handling and safe onsite storage of cladding sheets. This will deliver cost/ time savings and reduce the potential for cladding damage that can occur through multiple handling of sheets.

Expanded Design Flexibility

The ability to produce any-length sheets opens up a whole new world of design and engineering possibilities for spectacular visual impacts.

Any-length Snap-line 45 panels enhance your ability to align the eye-catching ribs for exciting horizontal, vertical or diagonal angle and plane contrasts.

Snap-line 45’s exceptional strength allows you to scale your vision to entirely new dimensions. Combining long-length sheets with other feature-rich building materials such as stone, timber, and glass delivers powerful aesthetic contrasts.

Standard cover widths include:

- 305mm

- 345mm

- 445mm

Custom widths are also available ranging from 200mm up to 600mm. Snap-line 45 products are made from superior Australian-made steel and designed to last. Expand your vision with Snap-line 45 and our roll onsite capabilities; truly the sky is the limit.