Specifying paints & coatings that meet sustainability & performance goals

Written by

13 August 2025

•

4 min read

For specifiers, every product choice affects both project performance and environmental impact, and paint and coatings are no exception. Today’s clients and certification frameworks require materials that meet strict sustainability standards without compromising quality. One leading New Zealand manufacturer is addressing the full lifecycle of its products, from ethical sourcing through to responsible disposal.

Heather Goode, Technical, Quality & Colour Services Manager at Dulux New Zealand, says their guiding vision is “creating a future without harm.” This approach embeds Kaitiakitanga (guardianship of the environment) into their strategy, inspired by te ao Māori principles and the expectations of specifiers and end-users.

Here, we speak to Heather about Dulux’s approach to sustainability and the significant measures they’ve taken to reduce environmental impact.

Ethical sourcing as product stewardship

Ethical sourcing is central to Dulux’s product stewardship approach, taking responsibility for the products they make, sell, and manage at end-of-life.

“This involves designing products to last, and establishing systems for their reuse and recycling when they reach the end of life. It shifts the burden of waste management from communities and councils to us as manufacturers,” shares Heather.

Specifiers can be confident that their products come from a supply chain built on integrity, as any material or product supplied to Dulux must meet strict environmental and social standards, and suppliers must complete detailed self-assessments (and for higher-volume suppliers, undergo in-person audits).

The company does not work with businesses involved in child or prison labour, or with convictions for fraud, bribery, or corruption. “This approach ensures that our supply chain reflects our values of integrity, transparency, and environmental responsibility,” Heather says.

Manufacturing with environmental excellence

Local manufacturing reduces transport emissions and supports jobs, and Dulux’s Lower Hutt manufacturing facility produces over 10 million litres of paint annually. It was the first paint production facility in the Southern Hemisphere to achieve ISO 14001 Environmental Management accreditation, in line with Dulux’s aim to be a market leader in environmental excellence.

“We focus on durability and protection, and quality long-term performance, but this is also a double-edged sword as our products are made with chemicals,” shares Heather. “We have made great progress in removing chemicals of concern, such as lead and mercury and developing superior-performing water-based paints, to replace flammable solvent-based ones.”

Dulux's R&D team is focused on low-VOC, high-performance coatings like Dulux Professional Enviro*, which is certified by Global GreenTag and Eco Choice Aotearoa. These products meet Green Star criteria and reduce indoor air pollutants.

Products such as UltraAir* and Enviro2* are recognised internationally for environmental performance, giving specifiers confidence in certification compliance and product quality.

Circularity in practice

Circular economy principles are built into Dulux’s operations, with manufacturing facilities and trade centres operating with 100% renewable energy.

Dulux’s paint Take-Back Service allows leftover paint and packaging to be returned to Dulux Trade Centres and selected depots for recycling, reuse, or safe disposal, and the Dulux EnviroWash* System was developed to turn paint wash-out into treated water and solid waste, providing a cleaner alternative to traditional tool washing.

Reducing product and packaging waste is another key focus area.

“Across our decorative brands, we incorporate nearly 35% recycled content from our post-consumer waste packaging,” says Heather. “This marks our efforts in building a circular economy within our packaging and minimises the virgin plastic that is brought into Aotearoa.”

Sustainability through community engagement

Heather says for Dulux, sustainability is as much about people as it is about products. Since 2013, Dulux has partnered with the Department of Conservation to restore community and DOC huts and regularly donates paint to charities such as summityourmountain.

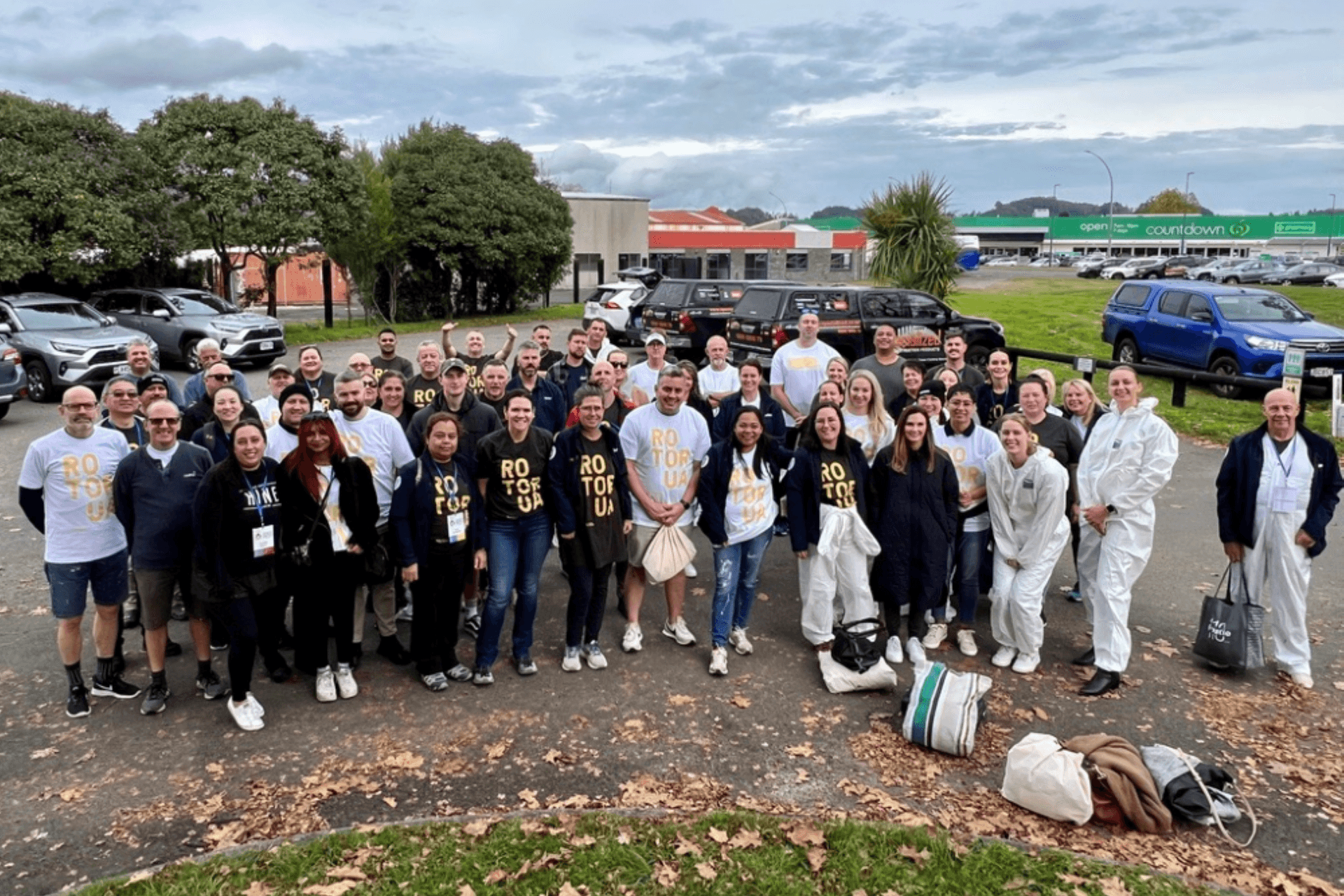

Community projects are part of team conferences, with recent work including painting the Rotorua Youth Centre, Pukehangi alleyway, and Te Pākarito Kohanga deck. Employees receive one paid day annually to participate in community activities.

Cabot’s Timber Finishes, part of the group, partners with Trees That Count, funding thousands of native tree plantings nationwide.

Looking ahead

The innovation pipeline focuses on reducing environmental impact at every stage, from sourcing to application to disposal, without compromising the performance expected by professional and DIY painters.

As Heather puts it, “We are continually developing new ways to reduce the environmental impact of our products, without affecting their outstanding performance and the quality results that New Zealand's professional and DIY painters have come to expect.”

For specifiers, this means a range of options that meet technical requirements while supporting environmental goals, helping deliver projects that protect both the built and natural environments.

Explore paint and coating products from Dulux

*Disclaimer: The Professional Enviro, Enviro2, Dulux EnviroWash, and UltraAir Systems are registered trademarks of Dulux.