The complex yet rewarding process of cladding the Aotea Centre

Written by

29 March 2022

•

4 min read

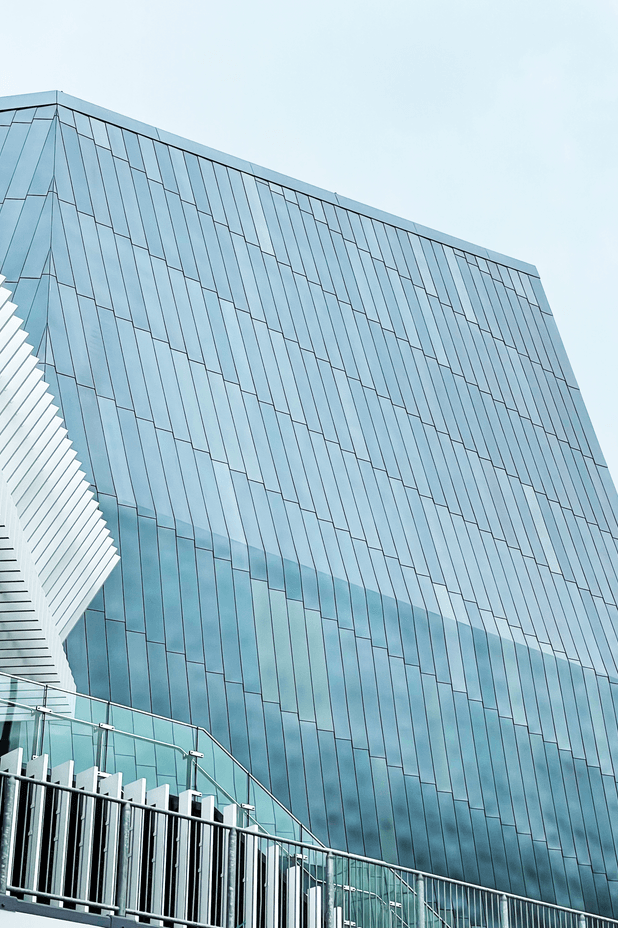

In October 2018, construction began on the exterior refurbishment of Auckland’s renowned Aotea Centre, a central fixture in the CBD’s architectural character since the early 1990s, but a building whose age and end-of-life materials were beginning to cause wide-spread water ingress issues.

While official work began in 2018, planning for the project went much further back. In the early 2010s, Auckland Council’s cultural arm Regional Facilities Auckland (now known as Auckland Unlimited) brought on architecture and engineering firm Stephenson & Turner (S&T) as contractors for the project.

Not long after, S&T engaged Architectural Metalformers (AMF) – a New Zealand-owned company that specialises in architectural roofing, cladding and sheet metal solutions.

“We were asked to come on board and assist with what was a very broad concept at that stage – of recladding the existing precast panel at the Aotea Centre,” says Mike Burgess, Project Manager at Architectural Metalformers.

S&T approached the company when the idea for an exterior cladding system comprising metal panels was solidified. Working with the S&T team, Architectural Metalformers provided guidance on the appropriate cladding system.

Roadblocks and rewards

Early design included assisting with the possible maximum size of the panel, to ensure economical use of the sheet sizes, fixing design and calculations on the potential thermal movement.

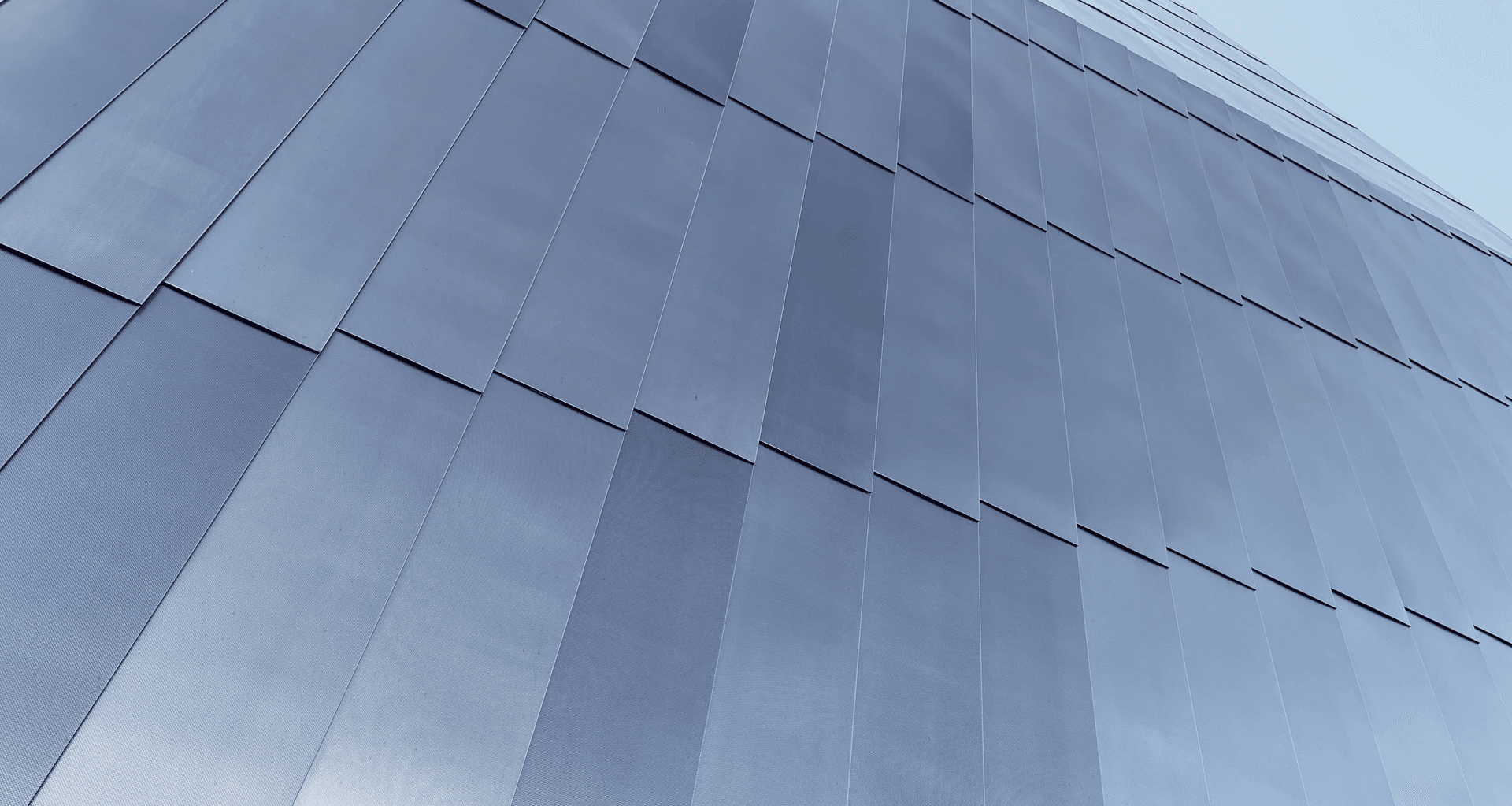

At this stage, it was decided that the correct system to suit the early renders of the building would be Flatlock Panel, installed in 2.300 x .450mm wide panels.

The original plan for the Flatlock Panel System included installing a typical 15mm plywood substrate, on a powder-coated aluminium extruded rail system over the existing precast panel wall cladding.

As is common with projects this complex and within the public sphere, the years began to pass. Dialogue between AMF and S&T regarding the project continued throughout this period, until the original quotation was provided in late 2017.

In 2017 the tragic Grenfell Fire in London drew intense scrutiny on flammable building materials and substrates across the world. This brought into question the Aotea Centre project’s use of plywood substrate.

“Work was very close to beginning on the site, but then after this development, they withdrew the use of plywood due to the possible combustibility,” says Mike. “This presented our R&D team to search for another solution, and ultimately we looked to move to another self-supporting panel system – Interlocking Panel.”

Fortunately, he says, they didn’t need to change the entire Flatlock system — just remove the substrate. But now, further testing was required to ascertain if Architectural Metalformers could install the originally proposed Flatlock system over just a rail without the plywood support to the rear — something not done before as all Flatlock profiles require a solid substrate.

“We did a second round of testing to see what the actual system could cope with and allow for the wind pressures on all the external corners of the building,” says Mike.

It was eventually decided to change the rail layout and orientation to provide further structural support to the rear of the panel. As the material was already being shipped, we decided to push forward with Flatlock Panel.

Work finally begins

In January 2019, Architectural Metalformers began the internal cladding process. This included installation of all diagonal lines for the new rail system — which proved difficult over an exposed aggregate precast panel.

Three months later, work stalled due to internal structure issues. This halted work on the project for the rest of the year.

In January 2020 AMF restarted onsite, with a small mobile factory assisting two teams of three to install panels to separate wall faces. Mike says the installation was difficult due to the deletion of the plywood, as well as the sheer size and geometry of the building — however the finished result is something the company is “extremely proud of”.

In November 2021 AMF installed the last of over 3,500 handmade panels.

With Architectural Metalformers work on the building 100% completed, Mike says that despite a long and complex process, which started over a decade ago, Architectural Metalformers are ecstatic with the result.

“In the past, we’ve worked on multiple heritage projects – for example, the iconic roof of the Auckland War Memorial Museum,” says Mike. “Many of our team have been lucky enough to work on projects that will stand the test of time. We can look back on them with pride at the workmanship and craft involved in complex work and it would be great for the next generation of staff at Architectural Metalformers to also have something to look back at and be proud of contributing to."

“From the outset, that’s how I viewed the Aotea Centre.”

Learn more about Architectural Metalformers and its offerings.