The dos and donts of insitu pours

We talk to industry experts, Dene Cook, Division Technical Manager for Fletcher Building and Concreteoligist, Ross Bannan, about vital tips and tricks to ensure you get your concrete insitu pours right to achieve exactly what you and your clients are after.

Ross Bannan from Bannan Construction has been guiding architects, designers and builders on the production of specialist architectural concrete for more than 25 years and has some amazing projects in his portfolio of work. He also has some handy tips for those looking to venture into the world of specialist concrete forms, surfaces and finishes.

“Concrete has the ability to go off very fast and it can go horribly wrong very quickly for obvious reasons and be very difficult to fix,” says Ross. “It’s not like you can just fire ahead as if you’re building a tree house. With an insitu pour it needs to be carefully planned out. I have had people come to me after they have completed most of their house to say they want a feature fireplace or wall. It needs to be factored in from the start of the design.”

Here are the key points from Ross:

- Know what you want to achieve and what your expectations are

- Spend the time and have a look around at what others have achieved

- Think ahead and do your research

- Plan and prepare well

- Put the proper processes in place

- You need to think about what services might be incorporated in the wall ie light fittings, switches, handrails etc

- Don't be afraid to ask for help.

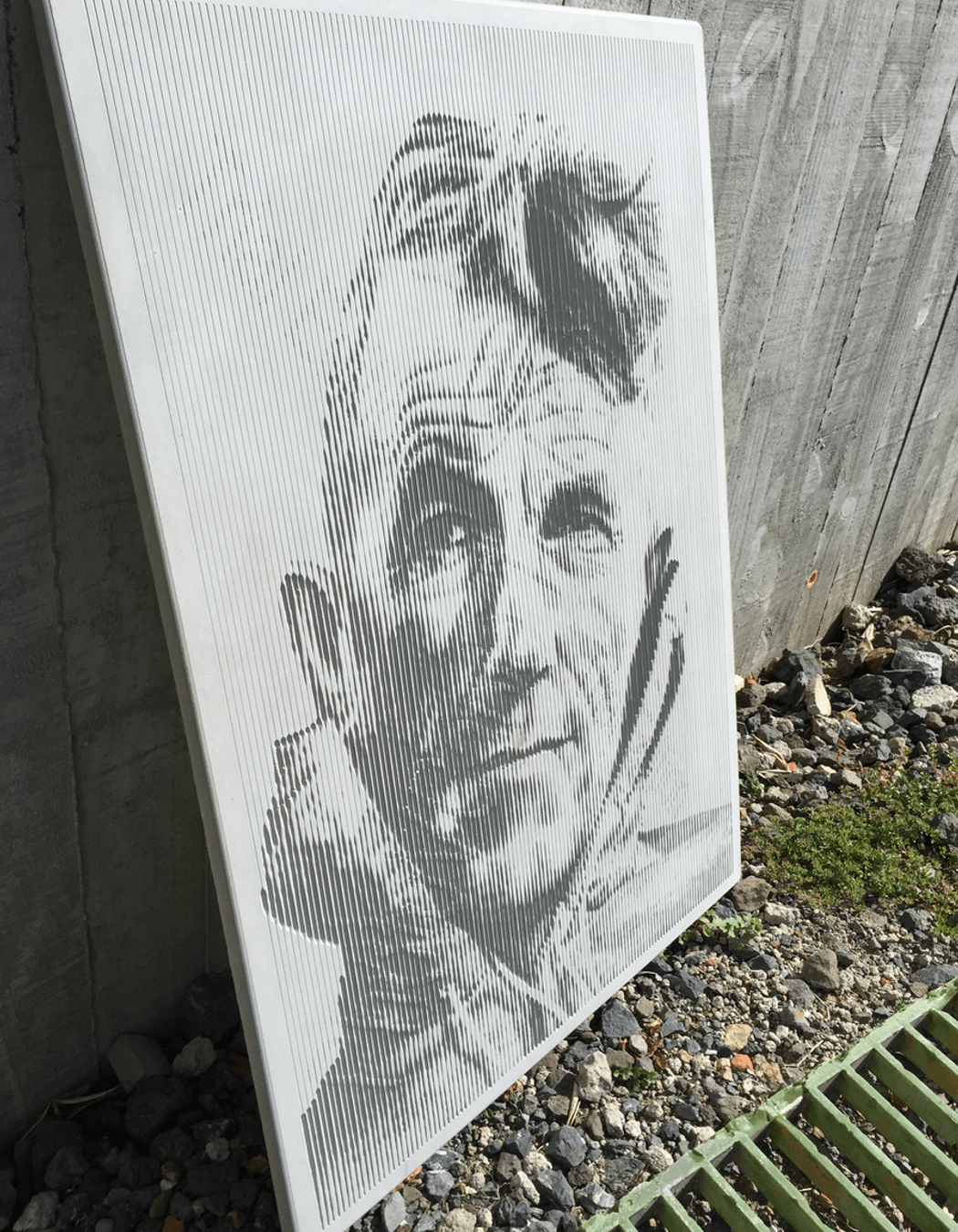

“Being a fluid product, with the right preparation you can achieve almost anything with concrete,” says Ross. “We’ve done everything from wall paper finishes to images of Sir Peter Blake and Sir Edmund Hillary. We can also use different colours and effects. The possibilities are endless.”

Ross says that if it's a decent sized project it is worth doing a reasonable size sample to understand the textures and what can be achieved rather than looking at an image and saying ‘that's what I want’. “The images are normally taken from five or six metres away so you can’t really see enough detail.”

Ross also advises people to use experienced contractors. “Talk to or engage people who know what they are dong and have been successful in the past. A lot can go wrong so talk to the experts who can explain and show you examples of what is possible. I have a number of very nice clients who are often happy for me to show people first hand a particular feature they may be wanting to achieve. Detailed planning and getting the right advice can make all the difference to the end result.”

“Most builders have traditionally only used timber for construction,” adds Ross. “I am doing my bit to teach builders about using concrete and what it is capable of. It’s about educating them and giving them confidence to use concrete instead of timber.”

Dene Cook, Technical Manager for Fletcher Building has been in the industry for more than 30 years and also has plenty of wisdom to share.

“Preparation is certainly the key point I would make when getting these pours right,” he says. “The formwork and the mixes are crucial.”

Dene suggests the following when undertaking insitu pours:

- The quality of the formwork dictates the quality of the finished surface. Defects in the formwork will reflect through to the final concrete finish.

- Concrete pressures can be considerable, the formwork needs to accommodate these pressures. Sometimes the forms are designed on the basis of an assumed fill rate. If this is the case then the information needs to be communicated to all.

- Form release agents can make a considerable difference to the final finished surface. Seek specialist advice. Oil based form oils tend to trap air and result in a greater number of bug holes. Bug holes are simply air pockets trapped against the formed surface.

- Plan the concrete pour so that delivery occurs at a rate consistent with the placing resources on the site.

- Consider back up equipment such as vibrators should breakdown occur.

- When filling forms avoid the concrete hitting reinforcement and forms on the way down. This invariably results in segregation. Use an elephant truck (flexible material that collapses flat when suspended), typically the truck diameter should be 6 times the maximum aggregate size.

- Place concrete as near as possible to final position. Do not move horizontally with vibrators. This can cause flow lines and discolouration.

- Take care placing concrete around box outs as air voids can occur underneath these. Place concrete from one side and provide air holes in the bottom boards (where practical).

- Place the concrete in uniform lifts of approximately 1.2m. Vibrate keeping vibrator vertical. Ensure the vibrator penetrates the lower lift by about 150mm. Observe the surface to determine the radius of effectiveness of the vibrator. Ensure that vibration overlaps.

- Do not let the vibrator touch the formwork as it will result in discolouration. Also avoid contact with the reinforcement.

- Ensure that forms are watertight to avoid grout loss and sections of boney concrete.