The Material & Technology Behind Aqvato Basins

Most people pause the first time they see a basin made from 3D-printed sand. The surface has a soft, yet tactile appearance. The form feels sculptural, almost carved, yet it’s clearly something different to stone or concrete. Naturally, the question that follows is: how can sand turn into something so durable you can use in a bathroom every day?

The answer lies in a manufacturing process that is equal parts design precision, and technical know-how. The Aqvato range is designed and produced in Germany by Sandhelden, who specialise in using their patented, quartz sand as the foundation for advanced additive manufacturing, technique. The idea is simple, but the execution has to be exact: start with a digital design, print it using the quartz sand, and transform it into something permanent.

The process begins with very fine quartz sand. Quartz sand is chosen because it is naturally strong and stable. The sand forms the core structure of the basin itself. To shape it, Sandhelden uses a technique known as binder-jetting, which is a type of 3D printing that is particularly suited to granular materials, such as sand. An exact digital model of the basin is created, whether that is one of Aqvato’s standard forms or a bespoke shape created for a custom project.

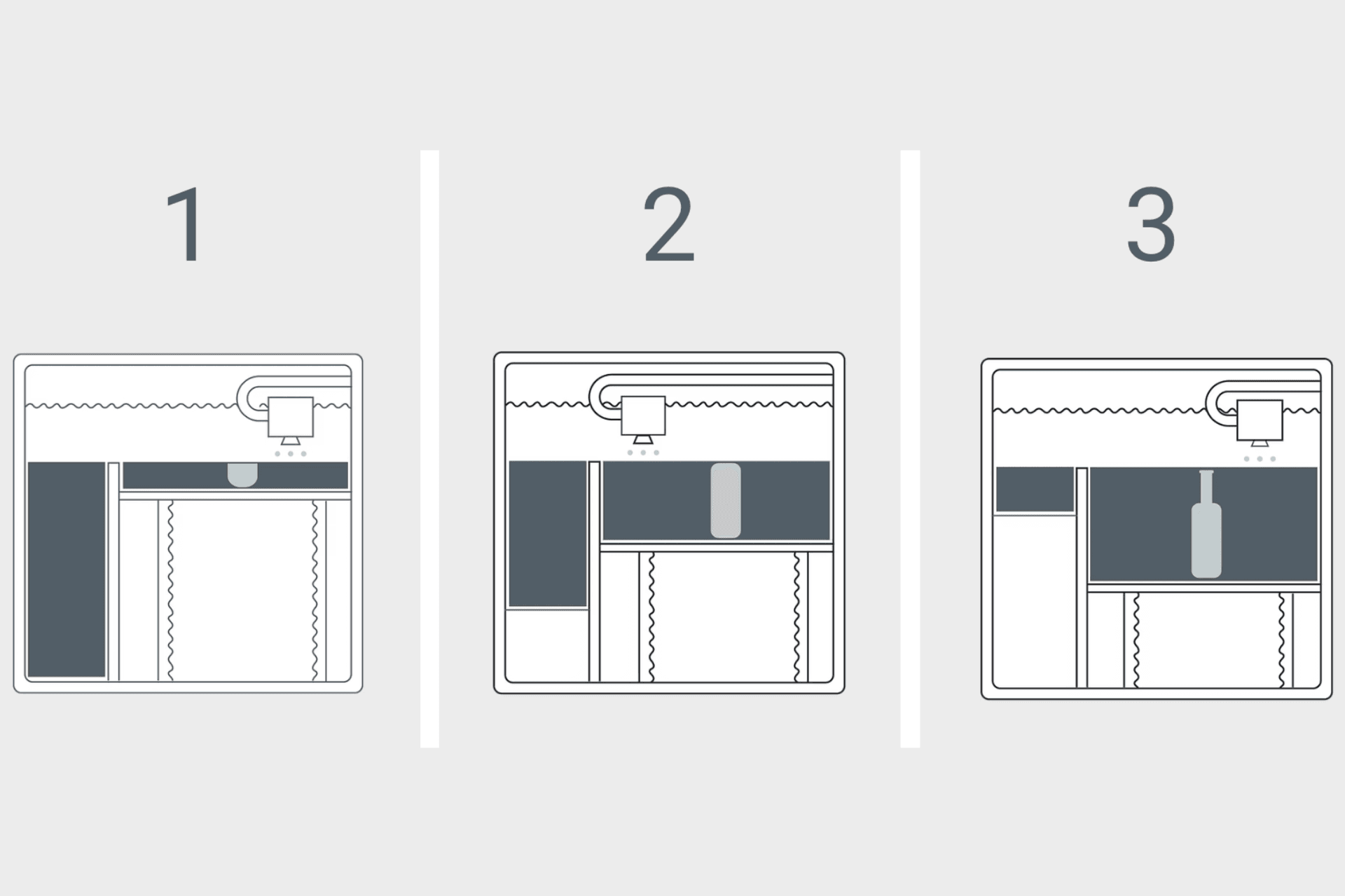

In the printer, a thin layer of sand is spread across a large flat bed, this is the preparation for the first layer. A print head then moves across the surface, releasing the liquid binding agent into the sand, creating the shape of a single horizontal segment of the basin.

The binding agent bonds the sand in those areas. Another layer of sand is laid down, and another layer of binder is printed on top. This process continues thousands of times, and layer by layer the full form gradually takes shape within a bed of sand.

Once the final layer is complete, the basin can be revealed by lifting it out of the sand bed, and brushing away the excess sand.

At this stage, the basin exists, but it is not yet strong enough to be used in a bathroom, or anywhere else for that matter. To transform it from its delicate printed form into a durable object, it goes through an infiltration process. A specialised strengthening agent is added, that absorbs into the structure, further binding the sand. What emerges feels solid; the sand remains visible and textured, but the structure has become durable.

The surface then receives its protective finishing treatment. This step defines the basin's final colour, and ensures it can withstand daily use with ease. First, the usable surfaces, are sanded smooth, and completely coated making it practical for daily use and cleaning. Then, the entire basin is coated in the chosen colour, as well as given a UV protectant coating to ensure the colour will stand up to daily use. The exterior of the basin is kept natural with the tactile sand texture, as to not disguise the material. A special coating is used on the outer part to ensure it does not cover this up, while still giving it the same waterproof, and UV protections as the inner bowl.

What makes this process special is not just how it is done, but what it allows. Because the basins are printed, not cast, their shapes can be created without requiring specific moulds. Therefore, proportions can be infinitely adjusted. Forms can be slimmed, deepened, and elongated based on the needs of your space. Customisation becomes a natural part of the design process rather than an exception.

If you’re designing a bathroom and are interested in working with form, texture and material expression differently, this is where the conversation begins. Experience the Aqvato range on our website, or in person at the Residium in Auckland.