The New Age of Decorative “Metal on Metal”

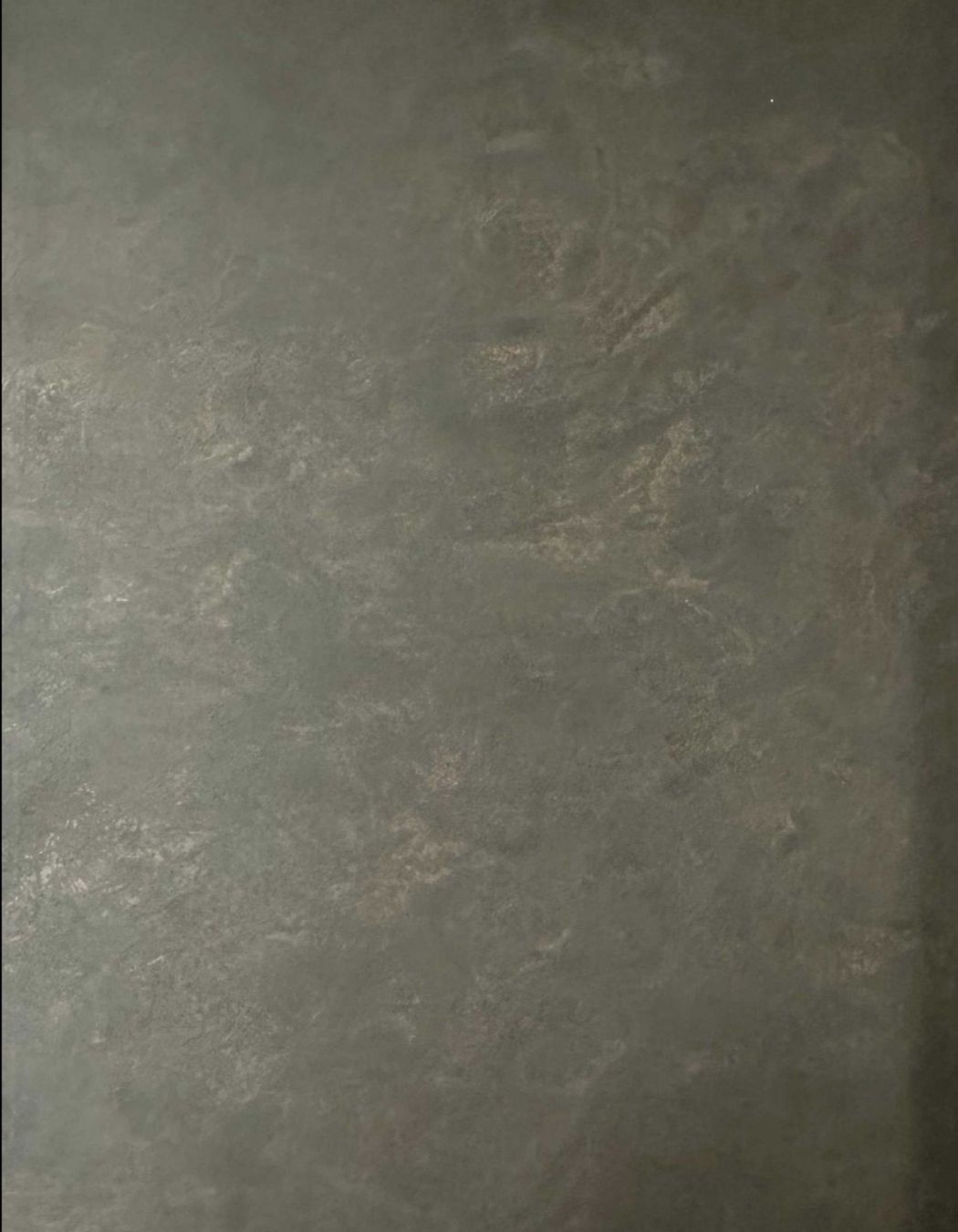

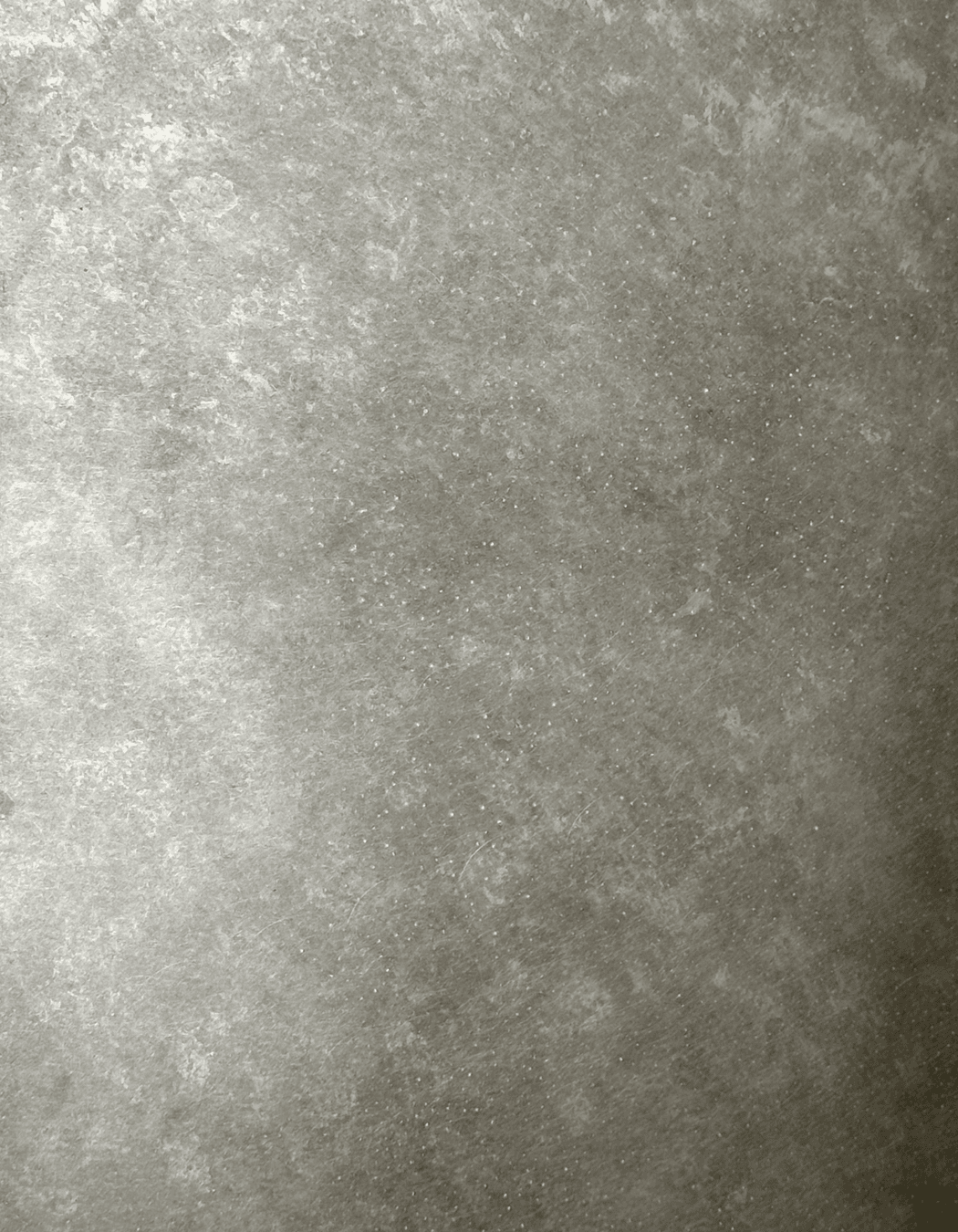

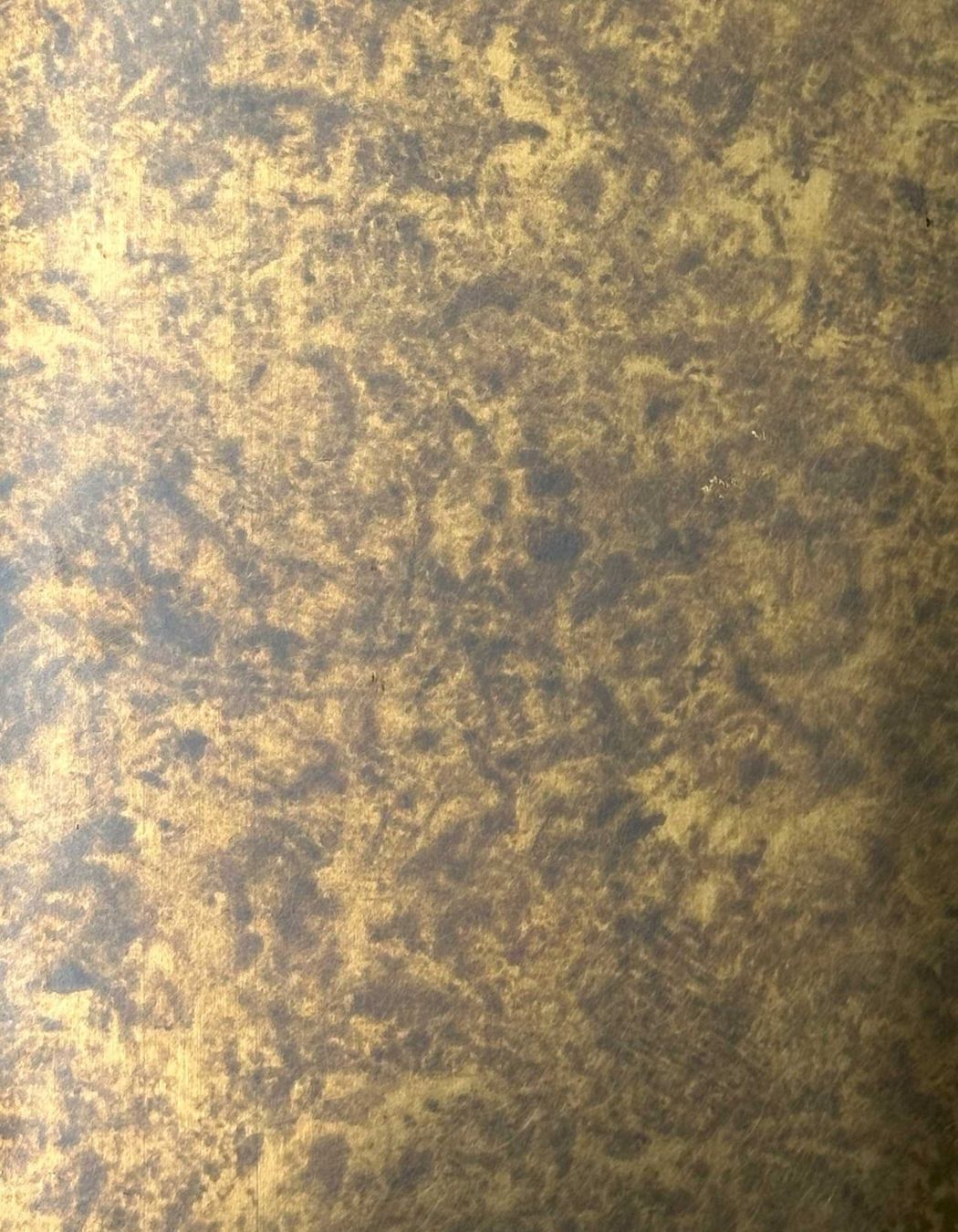

Electrocoated Stainless Steel

Electrocoated Stainless Steel finishes present a true metal alternative where actual non-ferrous metals are electrochemically transferred onto stainless steel sheets.

A further series of treatments to the transferred metal surface presents weathered appearances which are then sealed with either matte (MAF) or gloss (GAF) anti-finger print coatings for protection and ease of maintenance.

Benefits & Advantages of Electrocoated Metal Surfaces

Electrocoated finishes provide an actual metal surface on stainless steel with the inherent mechanical properties of the substrate for fabrication and installation.

At a fraction of the cost of traditional pre-weathered Copper alloys and alternate architectural metals. Electrocoated finishes are stable in look and very easy to maintain used for a variety of vertical decorative Internal applications.

The process provides a tighter visual tolerance between sheets than locally weathered materials. Although minor batch variation is to be accepted.

Fabrication & Areas of Use

Like PVD coatings the Electrocoated finishes cut, fold and form easily with traditional sheet metal methods along with laser cutting. However welding should be avoided to preserve the microns of finished coating applied.

Anti-finger print coatings remove trafficking issues and seize any further weathering which can show on the surface of non ferrous metals. It also assists with ease while cleaning.

Used in a variety of INTERNAL Residential and Commercial spaces like:- lobbies, wall cladding, reveals, lift carts, lift doors, splash backs, island and reception fronts, cabinetry facings, entrances, shelves, fireplace fronts etc. Anywhere requiring the feel of a natural living metal with stability.

Sheet Sizes, Availability & Specification

An available ex-stock range will grow as popularity for specific finishes increases. Sheets are generally 3000 x 1219 x 1.0mm with laser film.

For any unique finishes, we can offer a 5-sheet minimum order in lengths 2438 or 3000mm in various thicknesses ex production.

Lead times ex-production for unique finishes are approximately 2.5 months from order placement to arrival.

Talk to the team to learn and see more of what finishes are possible to SPECIFY. From smooth to textured stainless surfaces, the options are vast.