The role of thermally broken aluminium windows in Aotearoa’s building future

In November 2021, a landmark change to the Building Code ushered in new standards for residential thermal efficiency. New climate zones were introduced, minimum R-values were raised, and rules around window and door joinery were altered.

Aluminium, by far the most popular type of joinery in New Zealand, is responsible for between 35 – 50% of heat loss in a building – so naturally, the material was a particular target of the new regulations. As a result, almost all aluminium joinery must be ‘thermally broken’ going forward.

But what does this mean, and how much does it shift the landscape of thermal efficiency in Aotearoa? ArchiPro spoke to Scott Thompson, the Marketing Manager at Altus Window Systems, who outlined his take on the H1 changes to the Building Code, the place of thermally broken windows in this context, and what solutions Altus Window Systems has to offer in this arena.

ArchiPro: Can you give me your take on the H1 changes to the Building Code, and how have they affected doors and windows in NZ?

Scott Thompson: The changes are the biggest in over a decade – overall I would say they’re good, and long overdue.

A good example of this is the changes to the climate zones. The previous version of H1 divided New Zealand into three climate zones with housing in Nelson and Queenstown in the same zone, despite their wildly disparate weather conditions. The new changes see us move to six climate zones which are more practically aligned with the types of weather experienced in each zone.

The most far-reaching impact of the changes is certainly the necessity for new homes to utilise thermally broken aluminium joinery in order to comply with the required performance standards. Thermally broken technology has been around for many years; in the past, Altus Window Systems would only supply a small amount of thermally broken product – but going forward, the overwhelming majority of what we sell will now be thermally broken.

Ramping up production levels to accommodate the change in volume has meant a big shift for manufacturers and others in the industry. It’s been an investment-intense exercise conducted under the added pressure of incredibly tight time frames – everyone has had to re-think and re-engineer their supply chains and manufacturing operations.

For the end consumer, however, the H1 changes are undoubtedly good news: better energy efficiency means warmer, drier, healthier homes with less energy required to heat or cool them – and who doesn’t want that?

AP: For those who are unfamiliar, can you explain what is meant by thermally broken joinery?

ST: The majority of window frames in New Zealand are made of aluminium. It’s popular because it’s an incredibly abundant and versatile metal – malleable, odourless, corrosion-resistant, lightweight and strong. It is also a good conductor.

Aluminium’s impressive qualities make it the perfect material with which to manufacture windows and doors – but its Achilles Heel is its ability to conduct heat.

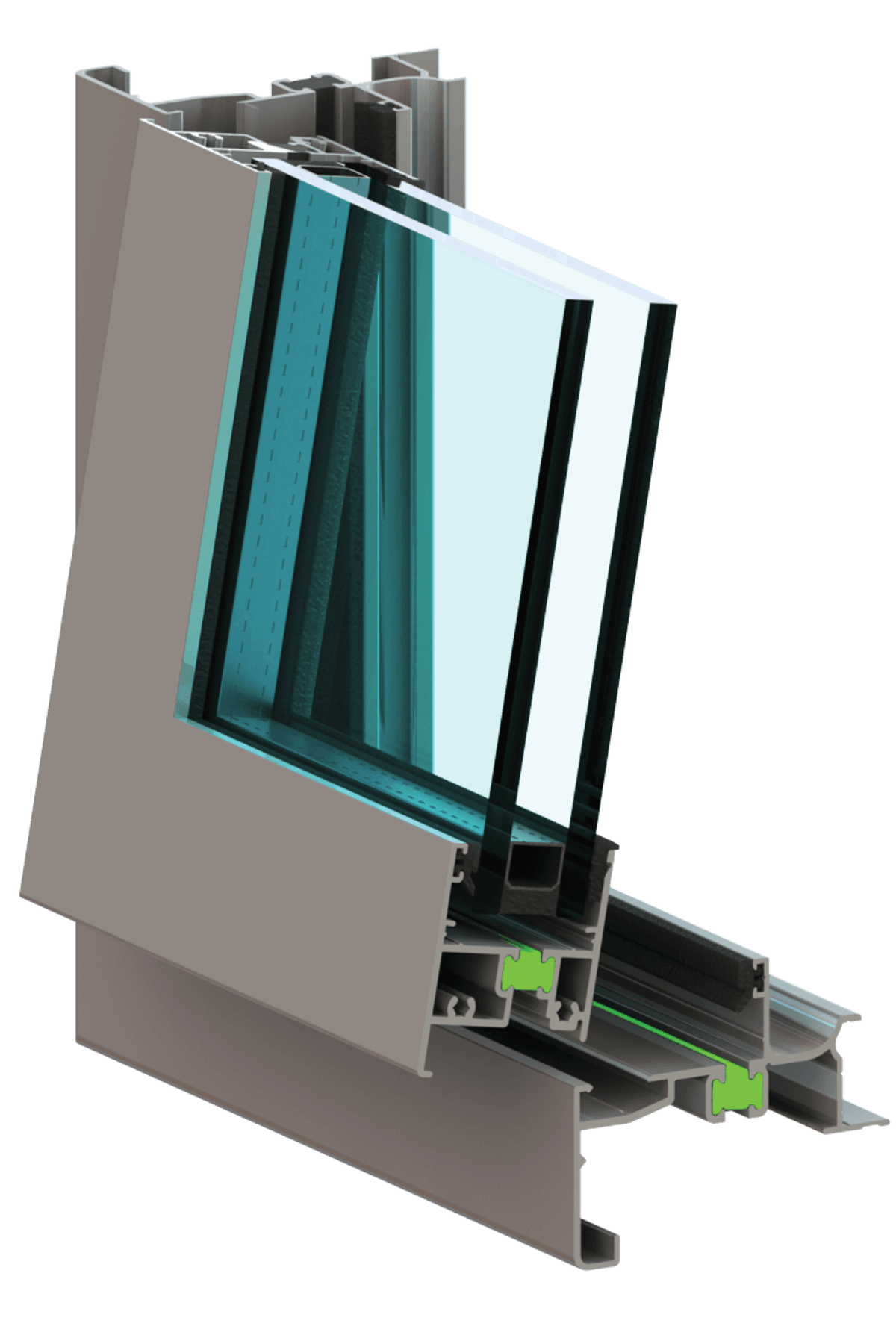

Think about a window frame – half of the frame sits outside in the cold, exposed to the weather. The other half sits inside the building where it is warm. Because aluminium is a good conductor, heat is able to move or transfer through the metal to the outside of the building resulting in a loss or a leak, effectively. This loss of heat means the homeowner has to keep the heater on in order to maintain a consistent temperature.

A thermally broken window frame combats this loss of heat by inserting a non-conductive strip between the two parts of the frame – the inside and the outside. The barrier essentially stops the transfer of heat from inside to out by separating the two parts of the frame.

With a thermal break in place, heat is not able to move past the inside of the frame, meaning the house retains its warmth and less energy is required to maintain a constant temperature.

Altus Window Systems' thermally broken product range includes our Southern41 Thermal and Pacific52 Thermal systems. These are two different systems employing different thermal technologies. Southern41 is the fastest and most dependable offer in the marketplace, while Pacific52 is our top thermal performer and a good high-end architectural solution.

AP: You mentioned that you have two different systems – can you elaborate on this?

ST: These two systems are distinct products manufactured using different thermal break technologies.

The Southern41 system employs what’s known as ‘pour and debridge’ technology to create an efficient glazing pocket size which delivers a good strength-to-size ratio in terms of thermal performance. This method of production is the leading technology in North America.

Our Pacific52 system on the other hand utilises a ‘polyamide strip’ to create a thermal break. This is the leading technology in Europe and offers fantastic flexibility of design. For example, the Pacific52 may be more suitable for situations where wider expanses of glass are called for or a larger glazing pocket width (for triple glazing) is required.

Of the two methods of manufacture, one is not necessarily better than the other. Building a house is not a one-size-fits-all situation, which is why we have persisted with and offer two thermally broken systems – homeowners should consult and choose the system that best suits their particular building situation.

AP: Why is it important to have thermally efficient joinery in 2023?

ST: With an estimated 35-50% of a building’s heat loss attributable to its windows and doors, it makes sense to look at ways to improve the insulative properties of this aspect of our buildings.

Thermally broken joinery stops the transfer of heat (or cold) between the inside of our homes and the outside. In practical terms, stopping this transfer will lead to households requiring less energy to heat (or cool) their homes and maintain a comfortable temperature.

On a micro level, this is good for the household – the money saved from heating or cooling the home could be put to better use. Then there are the health benefits; a warmer drier home means less chance of dampness and mould and the accompanying implications.

On a macro level, it’s good for the nation – fewer spikes in energy demand would hopefully mean burning less imported coal at Huntly Power Station in order to prop up the National Grid. As a country, we would be less dependent on an imported commodity, not to mention the cost or the carbon footprint of getting that commodity to us.

These are not just one-off benefits calculated over the length of one harsh winter or a record-breaking summer. These benefits are recurring and cumulative year-on-year, over the lifetime of the building in question.

Solutions to climate change lie in the application of science and technology to a particular problem. Thermally broken joinery, moved into the mainstream by the H1 changes, does exactly that – it provides an actual solution to an actual problem through the deployment of technology.

At Altus Window Systems, we've been working with this thermal technology for over 20 years, which is why we support the H1 changes and believe that we have a compelling thermal offering.

Learn more about Altus Window Systems and its services.

*Southern41TM Thermal and Pacific52TM Thermal systems are registered trademarks of Altus Window Systems