Thinking of polished concrete floors? Here's what you need to know

Written by

09 May 2024

•

4 min read

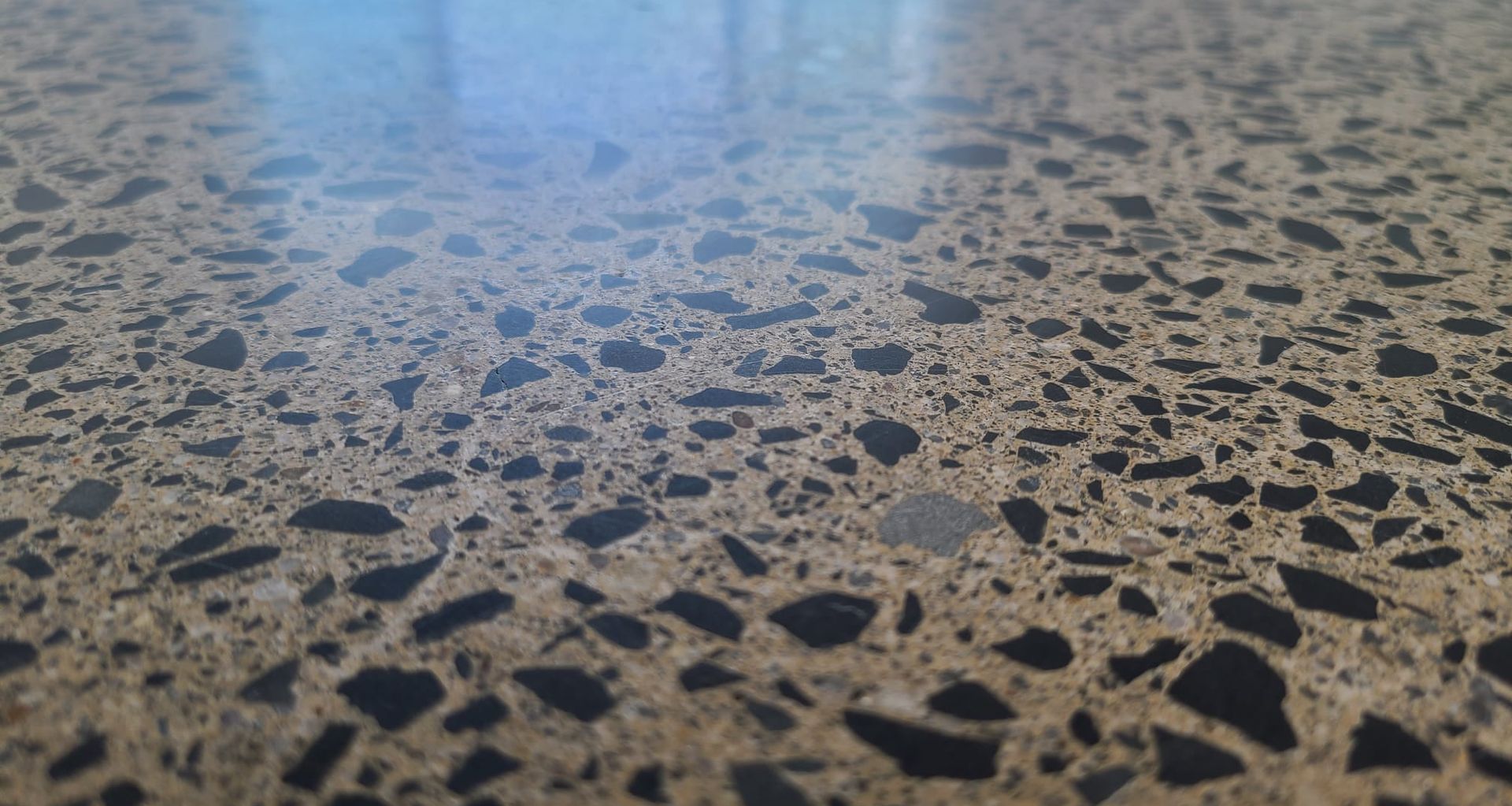

When it comes to flooring options, the attraction of polished concrete is undeniable. Its seamless blend of aesthetics, durability, and cost-effectiveness has made it a preferred choice for both residential and commercial spaces alike. In this comprehensive guide, we spoke to JJS FloorSpec director Rudi Beukes to delve deeper into the world of polished concrete floors, uncovering the myriad benefits, the polishing process, and everything in between.

Cost-effective and durable

“In addition to the lower initial cost, polished concrete offers long-term savings due to its durability and low maintenance requirements. Unlike materials like vinyl or carpet, which may require regular replacement or refinishing, polished concrete is exceptionally durable and resistant to wear and tear,” says Beukes. “This means fewer repair and replacement costs over the lifespan of the floor.”

The installation process involves refining the existing concrete surface, eliminating the need for additional materials like carpet or hardwood planks. This not only translates to significant cost savings, especially for larger areas, but also reduces environmental impact by minimising material usage.

Polished concrete also offers long-term savings. Its inherent durability and low maintenance requirements mean fewer repair and replacement costs over its lifespan.

Maintenance made effortless

One of the most appealing aspects of polished concrete floors is ease of maintenance. Unlike other flooring options that demand specialised cleaners or refinishing treatments, polished concrete simply requires regular mopping or occasional buffing to retain its shine.

“In high-traffic areas, polished concrete tends to maintain its appearance and structural integrity for longer periods with minimal maintenance,” says Beuke.

This simplicity in maintenance not only saves time and effort but also translates to lower cleaning and upkeep expenses in the long run.

Furthermore, polished concrete floors contribute to better indoor air quality. By resisting allergens and dust mites, they create a healthier environment for occupants—a crucial consideration for those with respiratory sensitivities or allergies.

Upgrading existing concrete floors

While the journey to polished concrete floors may encounter challenges such as surface cracks, unevenness, or existing coatings, these obstacles can be overcome through proper surface preparation techniques and the utilisation of suitable repair materials.

Solutions such as self-levelling concrete and epoxy coatings offer effective remedies for correcting imperfections and enhancing the durability of concrete floors.

JJS Floorpec specialises in upgrading existing concrete surfaces and has a wealth of expertise in self-levelling and epoxy coatings. A professional assessment can help determine the extent of the damage and the appropriate course of action, says Beuke.

“Self-levelling concrete is a specialised mixture designed to flow and level itself, making it ideal for correcting uneven or damaged concrete surfaces. It fills in low spots, smoothes out rough areas, and creates a uniform surface, improving the overall appearance and functionality of the floor.”

Epoxy coatings can effectively conceal imperfections such as cracks, stains, and uneven surfaces in existing concrete floors.

“They provide a smooth, seamless finish that enhances the appearance of the floor while also adding a layer of protection against abrasion, chemicals, and moisture.”

The epoxy coating bonds tightly to the concrete substrate, forming a seamless barrier that protects the underlying concrete and extends its lifespan, especially in high-traffic or industrial environments.

Harnessing energy efficiency & environmental sustainability

Beyond its economic benefits, polished concrete floors can also contribute to energy efficiency. With exceptional thermal mass properties, they absorb and store heat during the day, releasing it slowly at night. This natural heat regulation helps reduce heating and cooling costs, making polished concrete an environmentally conscious choice for sustainable building practices.

Moreover, polished concrete floors exemplify environmental friendliness.

“Using the existing concrete slab as the finished floor surface reduces the need for additional materials, such as hardwood or carpet, which can have environmental impacts during manufacturing and disposal,”shares Beuke. “Additionally, polished concrete does not require harsh chemicals for cleaning and maintenance, making it an environmentally friendly flooring option.”

Demystifying the polishing process

The journey to polished concrete floors involves a meticulous process encompassing preparation, grinding, honing, polishing, and sealing. Each step plays a vital role in achieving the desired level of sheen, durability, and aesthetic appeal.

Preparation: This involves cleaning the surface thoroughly and repairing any cracks or damages.

Grinding: Coarse grinding with diamond-embedded tools removes imperfections and smoothens the surface.

Honing: Fine grinding further refines the surface, enhancing its smoothness.

Polishing: Polishing compounds and densifiers are applied to achieve the desired level of sheen and durability.

Sealing: Finally, a sealant is applied to protect the surface and enhance its longevity.

Before embarking on the transformation of existing concrete floors, factors such as the current condition of the concrete, desired aesthetic and functionality, budget constraints, maintenance requirements, and expected foot traffic and use must be carefully considered.

To find out more speak to the experts at JJS FloorSpec