Unraveling textile testing - Abrasion Resistance

Test results provide us with critical information about a textile’s durability and suitability for certain applications, allowing us to make appropriate recommendations about usage. We externally test all James Dunlop and Mokum textiles in Melbourne at a highly reputable laboratory who are amongst the most conservative and stringent in the world, due to the extremely harsh environmental conditions we face here in Australia and New Zealand.

We have gathered a number of frequently asked questions relating to abrasion so we asked our Mokum Studio designers Stephanie Moffitt and Annie Moir to share their expert knowledge.

We understand you have a set of non-negotiable tests that each textile must pass to make it into range, which you refer to “gateway” tests in your development process. One of the important gateway tests for an upholstery textile is that of abrasion resistance.

WHAT DOES “ABRASION RESISTANCE” ACTUALLY MEAN?

Simply put, abrasion resistance determines a textiles ability to withstand the deterioration or break down of yarns through surface friction as would occur in use through the contact rubbing of fabric on your chair or sofa at home or in your project.

OUR SAMPLING AND WEBSITE OFTEN LIST TWO ABRASION RESULTS; “MARTINDALE CYCLES” AND “WYZENBEEK DOUBLE RUBS”, WHY DO WE LIST BOTH?

Martindale Cycles is the British Standard, also recognised in Europe, Australia and New Zealand. Wyzenbeek Double Rubs is the North American standard. They are mutually exclusive tests performed on different machines and with different methodologies, so a high result in one test does not determine or infer a high result in the other, they stand as separate results with no correlation.

HOW ARE THESE TWO ABRASION TESTS ACTUALLY PERFORMED?

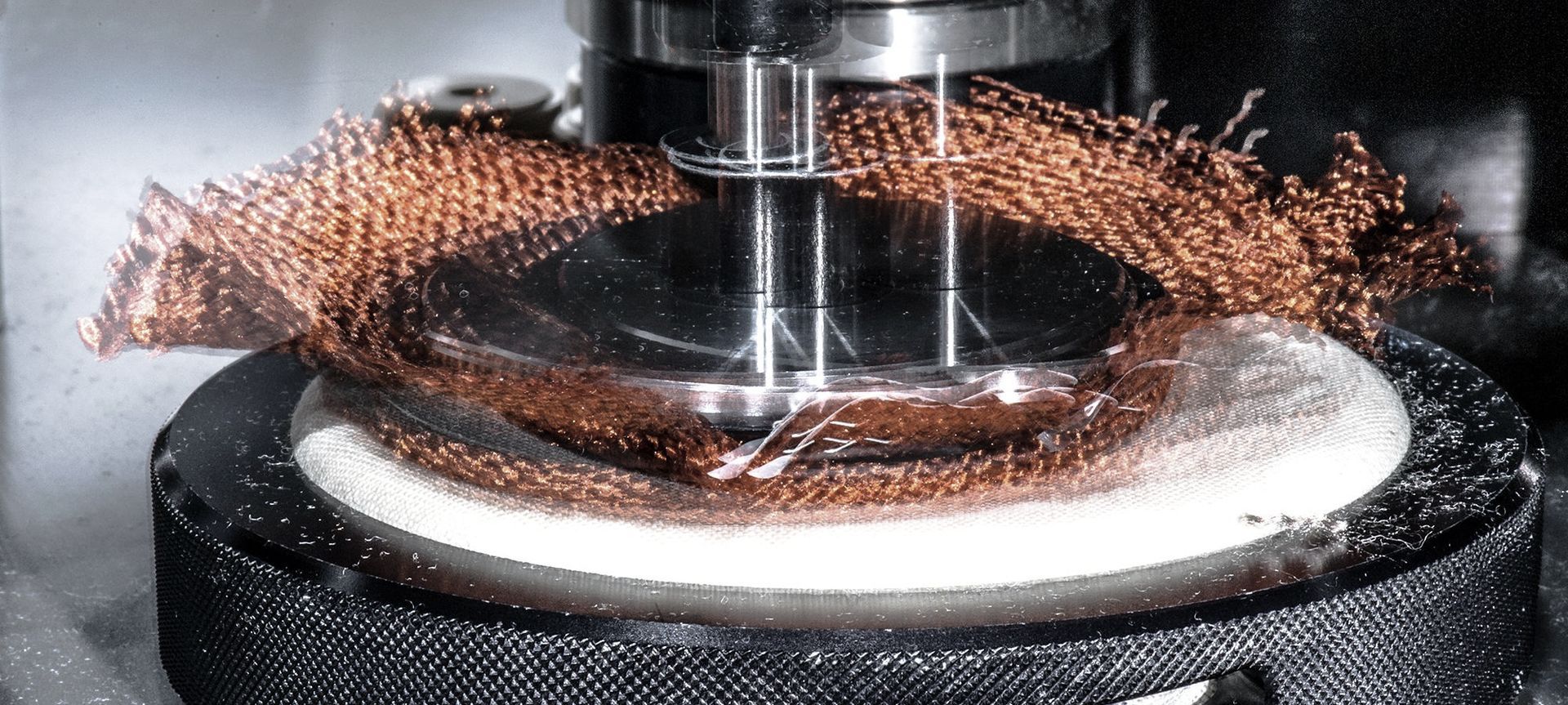

For the Martindale Cycles test a small piece of the fabric (known as the testing swatch) is wrapped around an oscillating head which is rubbed against a standard abradant (wire mesh or cotton duck) in an irregularly looping figure-8 type motion. The machine is motor driven with an electronic digital counter to measure the number of loop cycles, or “rubs”. The end point is when two adjacent yarns break, or in the case of a pile fabric such as velvet the test will end when the pile has completely worn away, or when the count reaches 100,000 rubs – whichever comes first! The machine is switched off at this point because a result higher than 100,000 rubs is not thought to be an indication of increased lifespan. The test is performed four separate times, a final average is drawn and the result is recorded on our sampling as a numerical rub rating.

The Wyzenbeek Double Rubs test is performed in a similar way, in that a series of small testing swatches are rubbed against a stationary abradant but in this case, instead of an oscillating motion it is has a backwards and forwards motion along both the warp and weft yarn directions. Again, the normal end point is when two adjacent yarns break, or the count reaches 100,000 rubs. Across the various tests, an average is drawn, recorded and listed on our sampling.

Essentially - the higher the number, the better the resistance to surface abrasion.

SO HOW SHOULD WE INTERPRET THESE NUMBERS?

The number is an indication of the level of surface resistance that for that particular textile. For example, Mokum’s upholstery design Nirvana lists a Martindale result of 20,000 – this implies that Nirvana will likely withstand 20,000 circulating rubs in the one isolated spot before the yarns actually begin to break. When you think about how long this would take to occur in use, this is an extremely high number.

CAN YOU EXPLAIN WHY A TEXTILE MIGHT RECEIVE VASTLY DIFFERENT RESULTS BETWEEN MARTINDALE AND WYZENBEEK?

From our experience, an abrasion result is very much impacted by the type of yarn construction being used on that particular test machine. As Martindale is performed in a circular motion and Wyzenbeek in a straight back and forth motion – different yarns and constructions cope differently under these differing stresses. For example Mokum’s Strata achieves a result of 100,000 Martindale Cycles and 40,000 Wyzenbeek Double Rubs, (both heavy duty commercial results), the difference is likely attributed to the chunky basket weave construction which is more durable against circular motion.

When in doubt, we always suggest referring to our recommended usage, noted on our website and sampling, to be confident you’re specifying a fabric that is fit for its intended purpose.

OVER THE PAST HALF-DECADE WE HAVE SEEN A GROWING MARKET TREND TOWARDS AN OVER SPECIFICATION OF ABRASION RUB RATES – WHAT ARE YOUR COMMENTS ON THIS?

Yes, it is definitely the case that abrasion resistance or ‘rub rates’ have been put on a pedestal, far higher than they deserve. Don’t get me wrong rubs rates are important, as they definitely provide some information as to a textiles potential durability, but they are not the single most important consideration when determining the likely performance of an upholstery fabric. In reality it is more likely that an issue could arise with seam slippage or pilling due to daily use long before the fabric will show signs of damage from abrasion. It’s also critical to consider maintenance factors such as cleaning – an abrasion test is not a mark of its day to day care, but purely an advice on surface wear. To help here we always ensure care instructions and any relevant finishes on the cloth that may contribute to care and maintenance are also noted on the website and sampling. To consider the rub test alone would be dangerous!

It’s not uncommon for us to hear “I want to reupholster my lounge room sofa and it needs to have 100,000 rubs”. We need an industry reset on this issue. It’s important to note that according to Australian standards 20,000 Martindale Cycles is considered heavy duty residential and exceeding 30,000 Martindale Cycles is considered a commercial rating, provided all other required upholstery tests are also achieved. Remember again that an abrasion test – for residential OR commercial, only makes up part of the puzzle of considerations.

IF YOU COULD SUMMARISE ONE KEY TAKEAWAY ON UPHOLSTERY TEST RESULTS, WHAT WOULD IT BE?

It’s really important to understand that abrasion results are just one piece of the puzzle, and they shouldn’t be viewed in isolation. The recommended usage from the fabric wholesaler is determined by considering all relevant external test results (never just one single result in isolation) as well as years of industry experience of the specific construction and composition of the textile – taking into account inherent characteristics of both these variables.

Clients should adhere to the recommended usage and care instructions set by your textile wholesaler when determining appropriate specification, as well as consulting with your upholstery manufacturer as there may be specific textile requirements for your chosen furniture frame.

If in doubt, or keen to understand more, you can always ask. Additionally, we have a wealth of product information published regularly on our website, there’s our industry guidebook Woven, plus our team of sales and customer service team members all of whom have a lot of information at their fingers and years of experience under their belts.