Warmset vs. Electric Cable

Key differences

Warmset

Warmset represents the “next generation” of electric underfloor heating—designed to meet the expectations of today’s customers: superior comfort, energy efficiency, sustainability, and safety. Thanks to its globally patented geometry and manufacturing technology, Warmset provides a smarter, more sustainable alternative to outdated cable systems. Whether for residential or commercial applications, Warmset is the intelligent choice for modern heating. Discover below the significant advantages that set Warmset apart from traditional electric cable mats.

Electric Cable

From a product evolution perspective, traditional electric cable heating systems have served the industry well, especially throughout the late 20th century and early 2000's, offering a simple and functional solution for underfloor heating needs. However, the core design—long copper cables arranged in loops or serpentine patterns—has seen little innovation over the decades. While these systems still function, they were developed in a very different era, before the advancements in materials science, precision engineering, and sustainable design we have access to today.

Core Heating

- Warmset: Heating is predominantly based on significant amounts of FIR, which penetrate the body/object deeply.

- Electric Cable: Heating is based predominantly on convection, with insignificant amount of FIR.

Heating Element

- Warmset: The heating ribbon is on average 6 times wider than a copper cable, radiating far more heat at parity of wattage.

- Electric Cable: Copper cables are usually between 0.75 - 1.25mm wide, considerably thinner than Warmset's ribbon.

Heating Coverage

- Warmset: Warmset covers about 40% of the entire surface with heating, meaning a uniform spread of heating across the room.

- Electric Cable: Electric cable mats cover about 15% of the entire surface with heating, leading to inevitable cold spots.

Geometry

- Warmset: Flat, wide geometry radiates waves of FIR in a perpendicular direction to the object that needs to be heated, which implies that the FIR waves are more direct therefore faster.

- Electric Cable: The rounded geometry of the copper cable implies that heat will radiate mostly in an oblique direction, meaning longer distance therefore longer times (and cost).

Energy Efficiency

- Warmset: Faster at reaching target temperature by at least 10% on average, Warmset works gently with temperatures between 22 and 35 degrees maximum. This implies less electricty being used, therefore cheaper to run. Also, heat is retained for longer because there is so much more density of radiating surface (40%).

- Electric Cable: Slower at reaching target temperature and works with excessive temperature peaks in stop-start duty, reaching up to 100 degrees Celsius. This cycles require more electricity consumption. The lower density (10-15%) implies working harder to maintain the target temperature.

Insulation

- Warmset: The heating core is protected by 5 layers of material (such as nickel and aluminium) on each side.

- Electric Cable: The copper cable is usually protected by at the most two layers, including the PVC jacket of the cable.

Safety & Grounding

- Warmset: Has a groundable outer insulation layer, which serves as a mechanical and environmental barrier, and an active safety conductor that can discharge moisture-related current before it becomes dangerous. This serves as a redundant safety mechanism if internal layers fail; Faster fault detection even before the damage reaches internal wires; Reduced voltage potential on the floor surface.

- Electric Cable: The better electric cable brands have an internal earth conductor, which provides basic fault protection. However, it does not allow the outermost jacket or insulation to be grounded: No reduction in step voltage under wet conditions, no protection if the outer jacket itself is compromised.

EMF and DE Emission

Warmset

- Certified by Nemko to be zero EMF. Nemko is one of the most respected certification authorities with locations all over the world.

- Warmset does not produce any Dirty Electricity and is not affected by the main home cabling (which produces DE).

Electric Cable

- We are not aware of any Australian brand being certified by a third party to be zero EMF. Many make the claim, but cannot produce an independent certification by a reliable authority.

- Electric cable mats usually produce DE because they are affected by the main home cabling.

Warranty

- Warmset: Warmset Gold comes with a lifetime warranty (the life of the floor first installed on the system).

- Electric Cable: Most come with a 10 year warranty, although a handful do come with a 25 year warranty.

Origin and Traceability

- Warmset: Warmset mats are 100% made in our factory in Italy. Every single mat is tested and tagged at the origin, deresking to near-zero the chance of receiving a faulty mat. Blockchain technology allows us to trace the entire lifecycle of the mat from raw material to finished product.

- Electric Cable: Most brands of electric cable UFH are sourced from high-volume factories in China/India that produce for many other brands; usually only batch spot-checks are performed at the factory and traceability of a mat varies.

Wattage

- Warmset: Can be custom-made in any wattage required by the specifics of your projects. In Australia, we often install 100W/sqm instead of 150W/sqm, reducing your energy requirement by 30% from the start.

- Electric Cable: Most mats sizes are only available in one wattage, which may not be the optimal level of power for your project. The only way to change the wattage per sqm is to have a system built on site with loose cable, which requires higher labor costs and can incur mistakes.

Sustainability

- Warmset: Warmset is 100% recyclable.

- Electric Cable: Copper must be stripped by its protective wire in order to be recycled, an expensive operation.

Customisation

- Warmset: Warmset can be manufactured in any lenght and wattage at no extra cost from as little as 100sqm. projects.

- Electric Cable: Electric cable mats cannot be customised because they are made in large-volume factories that require high minimum order numbers.

Time to Reach Target Temperature

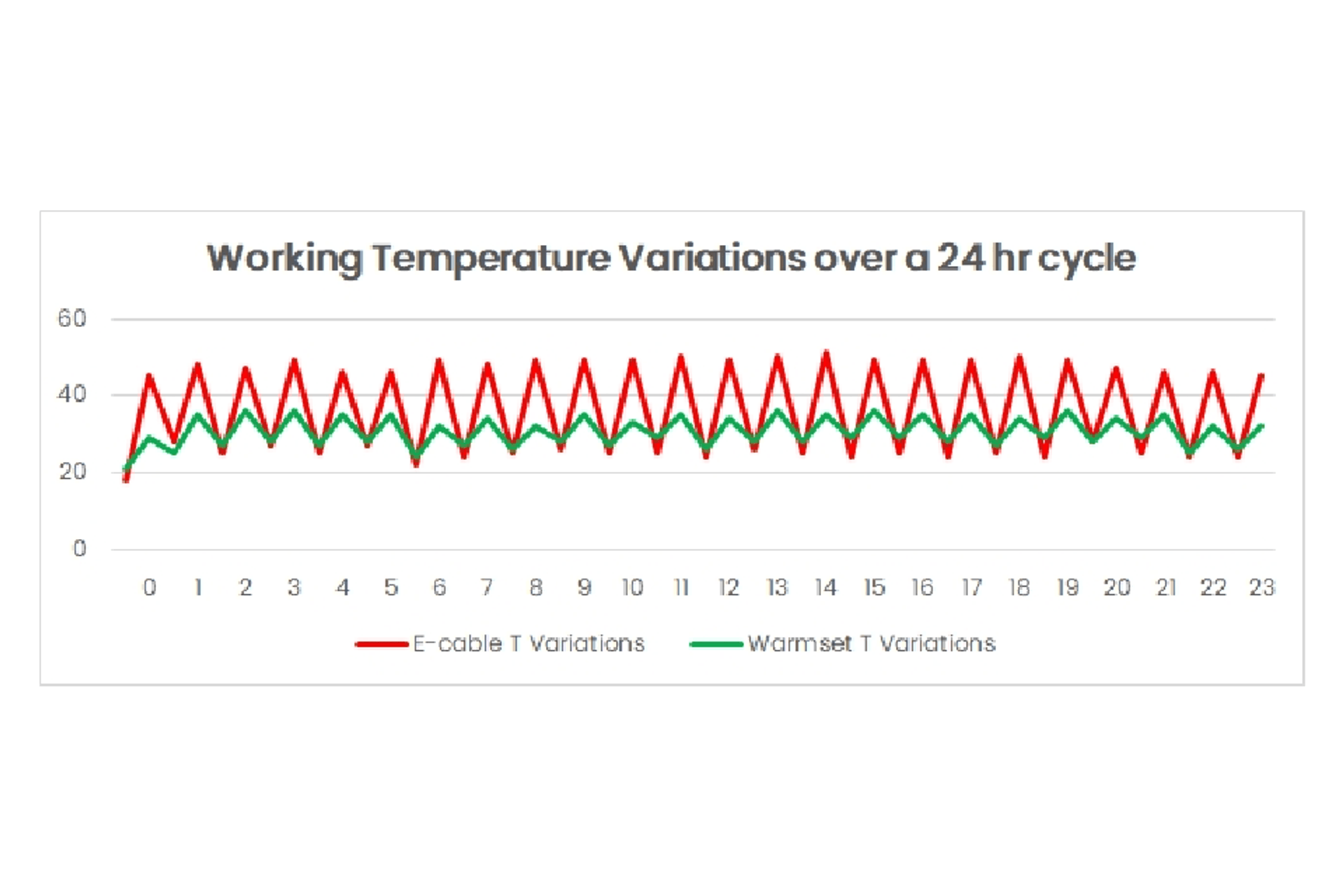

In this graph, we compare the heating element temperature over a 24-hour cycle of both Warmset and the leading electric cable mat in the world. The floor temperture was set at 20 degrees Celsius. The floor was tiled directly onto the mats with flexible adhesive. We can see that, in order to maintain the targeted temperature, Warmset works gently with spikes between 22 - 35 degrees, whereas the electric cable mat must work harder, with consistent spikes up to 50 degrees.

Ongoing Operating Temperatures

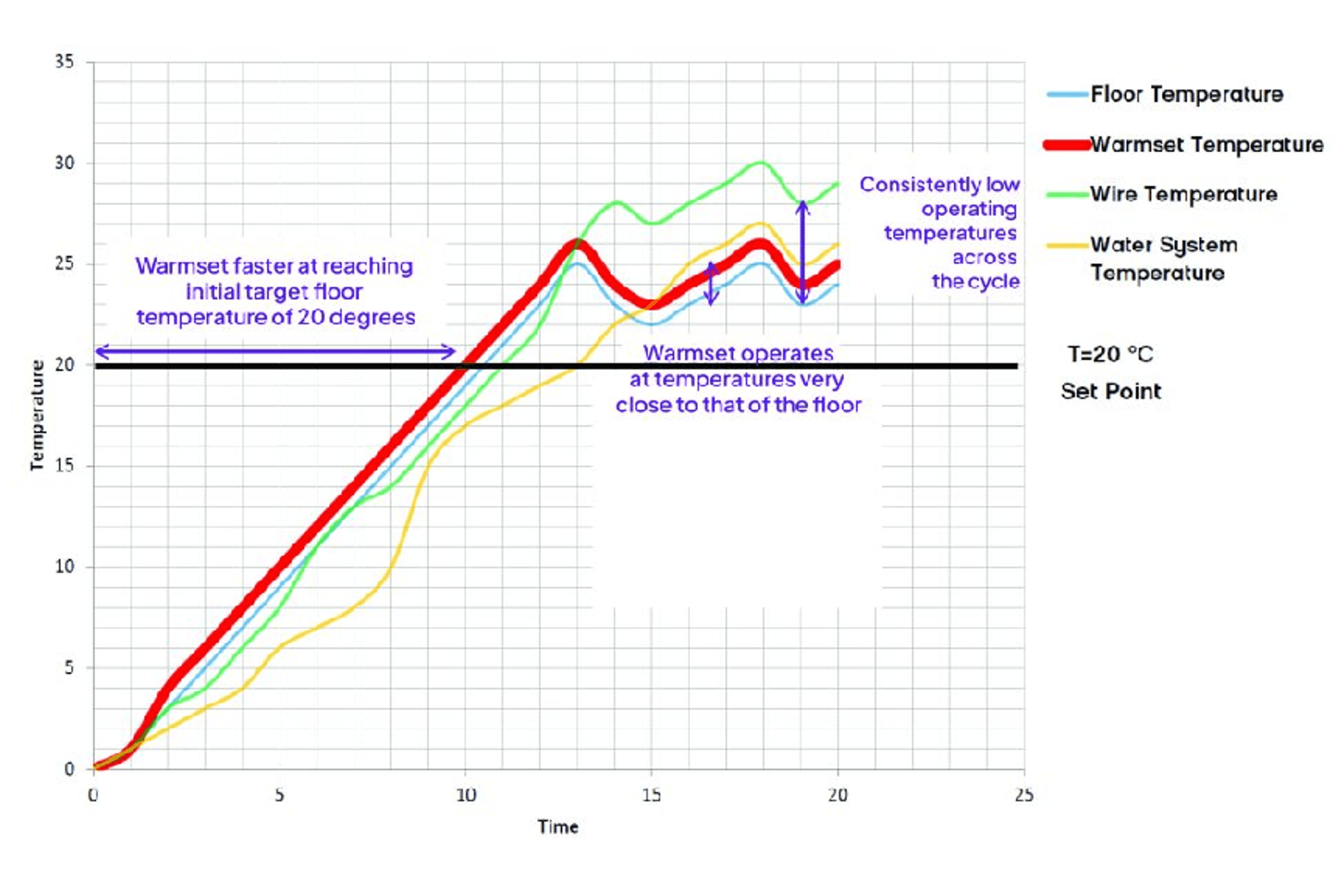

In this graph, part of a different test, we compare the speed and operating temperatures of Warmset, electric cable and hydronic underfloor heating. Warmset's powerful FIR reach the target floor temperature of 20 degrees 10% faster than the electric cable and 30% faster than hydronic coils. Similarly to the previous test, Warmset continues to operate at gentle temperatures, similar to hydronic (in fact 1 degree lower).