What lies beneath: how recycled glass is being used to create green insulation

Written by

15 June 2020

•

3 min read

There’s nothing new under the sun; so goes the saying and in a lot of instances that’s true. That doesn’t mean however, that an existing product isn’t as innovative today as it was when it was first conceived. Take FOAMGLAS® cellular glass insulation, for example.

“FOAMGLAS cellular glass insulation was developed in the 1930s,” says Josh Mainwaring, Director of Accumen Shapes. “It is a high-performance, rigid glass insulation product specifically designed for industrial, building and roofing applications, providing performance that is unachievable with any other building insulation.

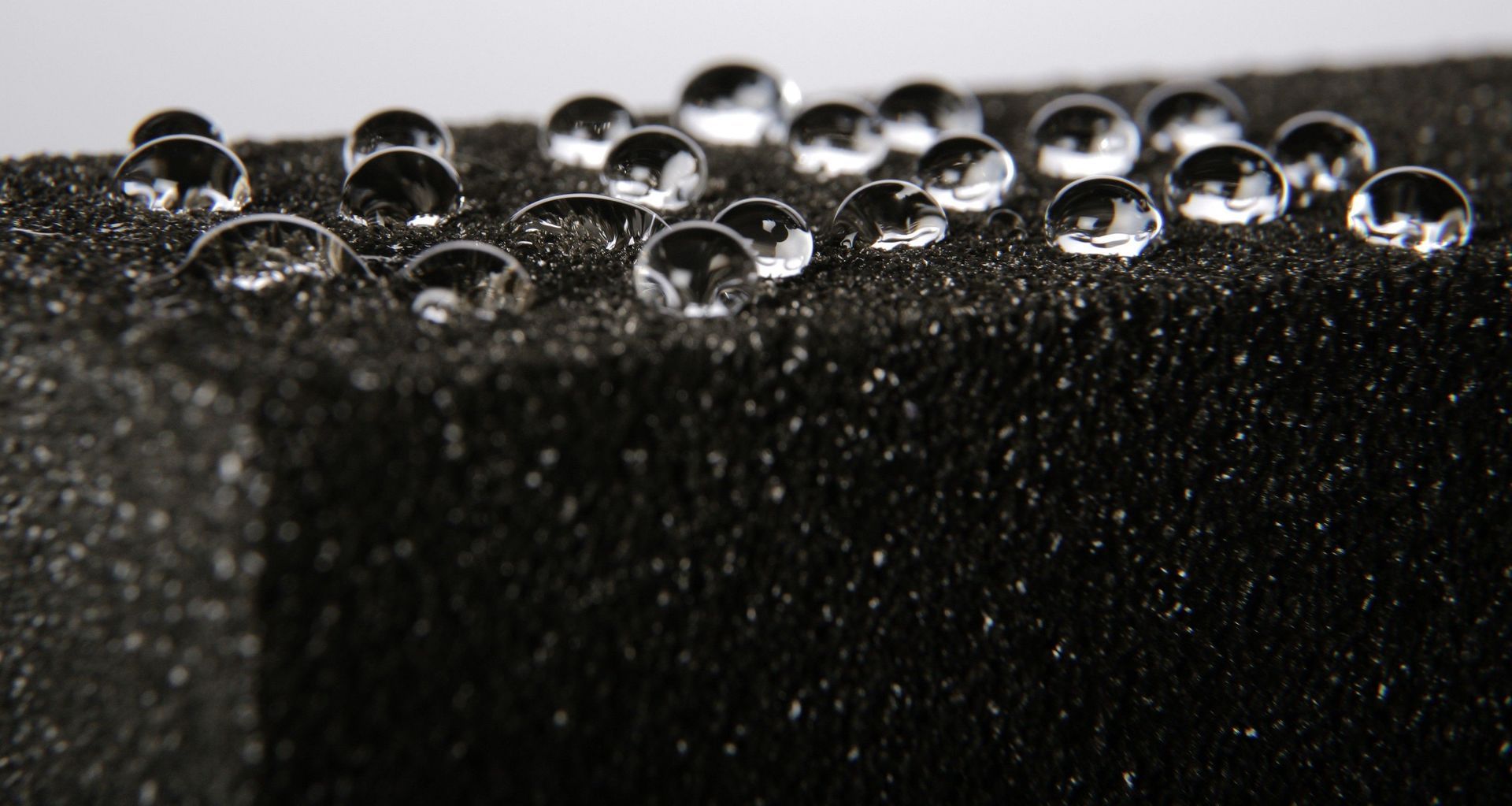

“FOAMGLAS performs across all of the significant areas—it is dimensionally stable, water tight, vapour impermeable, anti-corrosive, non-combustible, vermin resistant and rates highly for compressive strength.”

SiO2-Na2O-CaO: the formula for success

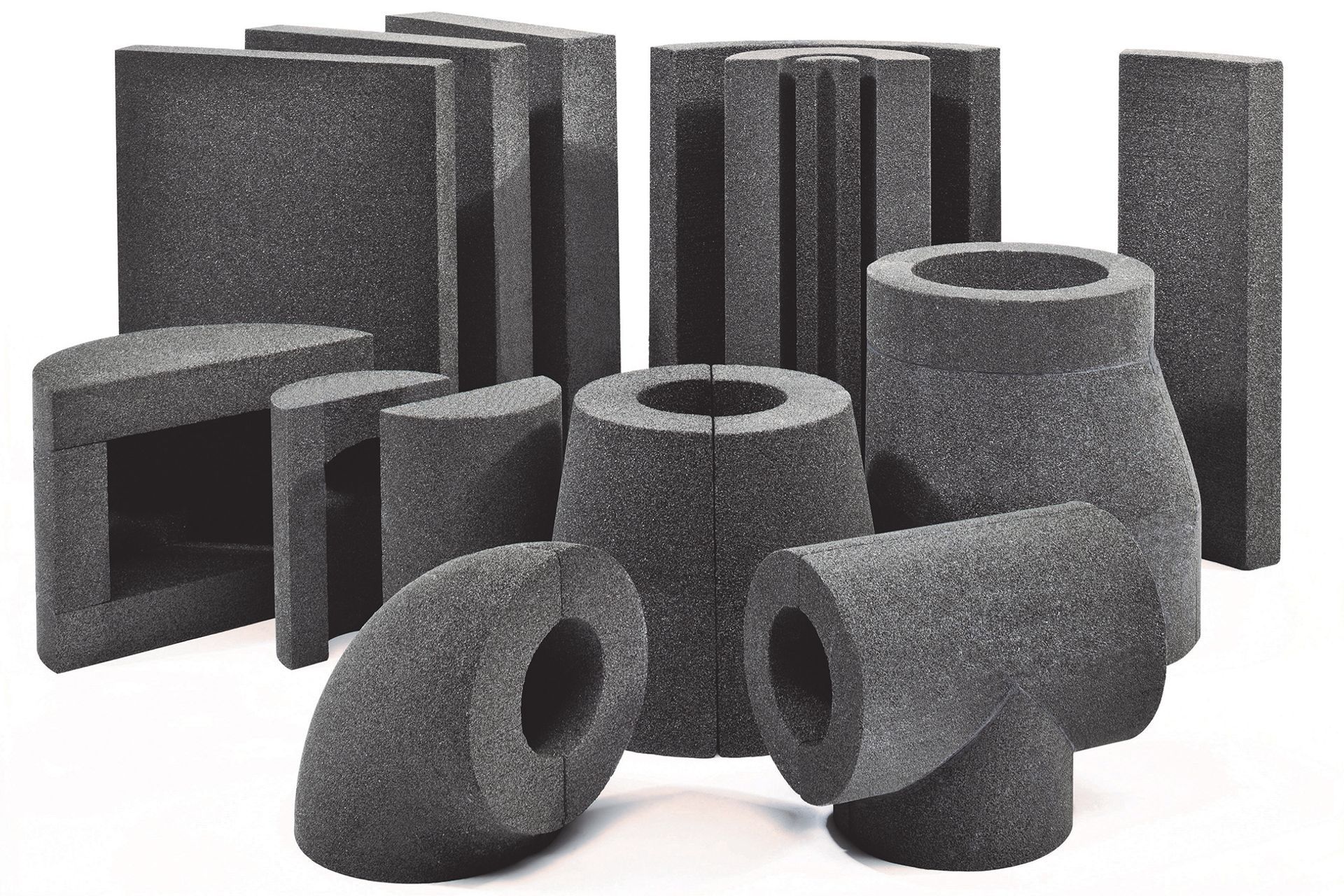

The secret to FOAMGLAS’ superiority is its composition, being made from granulated glass that is heated to near melting point before a chemical foaming agent is introduced, which causes a foaming effect in the glass. After cooling, the result is a rigid material—comprising gas-filled closed-cell pores—which can be cut and shaped as required.

“FOAMGLAS is particularly suited for use in what the industry classifies as ‘mission-critical’ buildings such as data centres, airports, government buildings, hospitals, convention centres, casinos, museums and the like,” says Josh.

“Similarly, because of its impressive operating temperature range (-200–430 °C), FOAMGLAS can be used in applications ranging from cryogenics through to high-heat insulation. It really is an all-encompassing material.”

Taking FOAMGLAS into the future

Josh says Accumen Shapes has recently become the New Zealand agent for FOAMGLAS by Owens Corning and the company has invested heavily in the necessary machinery to process the raw material into custom sizes and shapes.

“FOAMGLAS has been available in New Zealand for a number of years now and has garnered a dedicated following in that time. When the opportunity arose to get involved in the distribution side we jumped at it, not just because the product speaks for itself but because of the reputation that Owens Corning has globally as a manufacturer fully committed to its products and the industries that use them.

“Customers can rest assured that not only are they investing in the best possible product but, also, that they have access to a comprehensive repository of information about that product.”

Green credentials: of the earth, for the earth

“Essentially, FOAMGLAS is predominantly composed of recycled glass with no hidden ‘nasties’ or CFCs, making it an environmentally responsible product from the start. Add to that it’s extended lifecycle and ability to be reused and recycled and its sustainable characteristics are assured.

“It can also be used in other environmentally friendly applications such as green roofs, where its lightweight and pest-resistant nature has made it a popular substrate choice.”

Learn more about FOAMGLAS insulation.