Avoiding costly mistakes in underfloor heating with Warm NZ

Written by

24 January 2017

•

5 min read

When underfloor heating is done right, it offers a cost-effective, versatile heating source suitable for both residential and large-scale commercial projects. Cheaper than traditional heat sources including air conditioning units, heat pumps and standalone heaters, it is also more sustainable, heating large areas and entire homes from a single heat source.

However, if the pipe layouts aren’t designed and installed properly to suit the build, the chances are, you’ll end up with a cumbersome system that actually creates more costs and requires more expenses on an ongoing basis, underfloor heating expert Sean Stephens of Warm NZ says. “That’s because the pipes need to be installed with correct spacing to suit building materials to maximise efficiency.”

Warm NZ has specialised in underfloor heating in New Zealand for the last two decades, working closely with German pipe manufacturer Rehau to develop a design system ensuring the best solution every time.

“Despite underfloor heating piping being classed as a plumbing material, it is not covered by the plumbing code in New Zealand and therefore does not have to be installed by a registered plumber,” Sean says. For the Warm NZ team, the lack of regulation means they’ve seen many poorly designed and installed systems underperforming and having to be turned off due to running costs.

And the horror stories are commonplace. At their worst, Sean says he’s seen potable water being run through the floor creating a health hazard; and significantly increased running costs as a result of pipework being placed too far apart requiring increased water temperatures to try and achieve an ambient temperature in the dwelling.

But, as Sean says, if you don’t get it right from the first step you have no chance to remedy once the concrete is poured. “As a result, we’ve developed our own stringent processes to ensure every job we are involved in is managed well from start to finish and the result is right every time.”

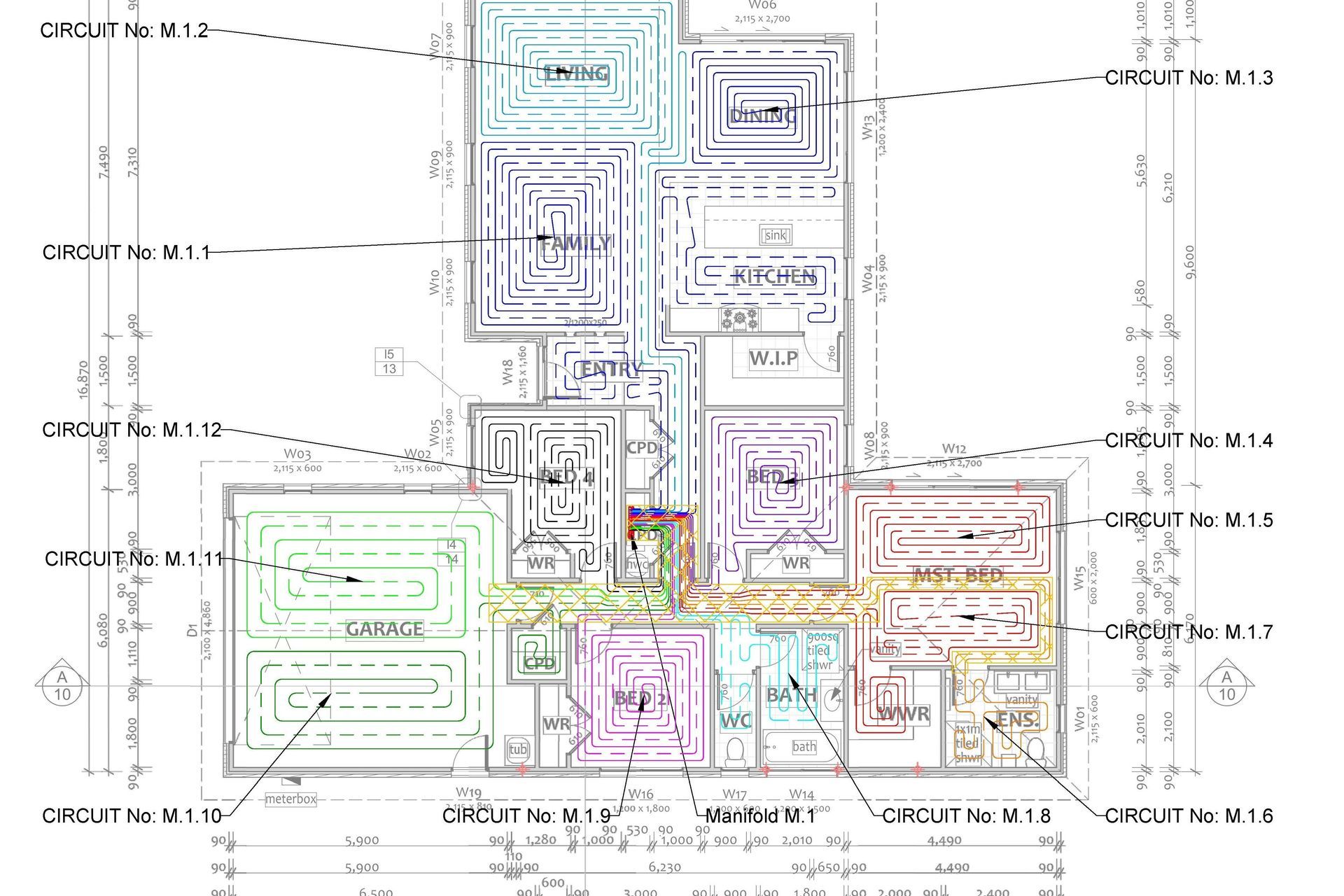

Warm NZ works with Rehau to offer a service unique in the underfloor heating sector in New Zealand. At the outset of every job after initial consultation with the client, Warm NZ liaise with Rehau’s team of heating engineers based in Rehau’s Australasian head office in Sydney to provide an initial design and a bill of materials.

“This stage is crucial because they work out the exact pipe design for the finished floor. Depending on the type of flooring – stone, wood, carpet etc – there is variance needed in the spacing between pipes to achieve the optimum result,” Sean says.

Warm NZ then take this estimate back to the client and once confirmation is received, a detailed design is undertaken by Rehau’s engineering team. This detailed design includes CAD drawings, hydraulic calculations, balancing and commissioning settings which can be attached to consent documentation, as well as providing a firm quote.

It’s a crucial process to ensure the product is installed in the manner in which it was designed to be utilised. It is when these designs aren’t being prepared that Sean and his team see jobs that have gone wrong and been installed without the required knowledge of the system and its requirements.

“Rehau is the pipeware manufacturer. This is their product and they have a team of engineers who work to provide accurate designs for installation of these systems,” Stephens says. “While going with the engineers’ designs is not necessarily the cheapest option, it ensures we get it right every time.” And provide the client with the cheapest running cost.

Underfloor heating runs from a heat source, either a gas boiler, diesel boiler or a heat pump, which heats the water to the desired temperature and sends it through the pipework installed in the floor – essentially turning the entire slab into an element of sorts.

If the floors are wooden, a diffusion plate is installed, which is an aluminium panel placed between the joists before the floor is laid. This panel has channels edged into it where the pipework is installed to heat the floor above.

Part of the initial planning and design phase for underfloor heating allows for clients to separate areas of a house or building into zones, which can then be operated separately with a programmable thermostat allowing controlled heating.

“We’ve seen underfloor heating growing in New Zealand consistently every year since we’ve been in the business,” Sean says. “People are realising it is a more sustainable heating option than many others, and its ongoing maintenance and operational costs are considerably less than other options because of its single heat source. But it has to done right and that’s something we’ve prided ourselves on. We’ve set our own benchmark and our own high levels of conduct and ethics within the industry.”

If you’re considering underfloor heating as a heat source for your next project, give the Warm NZ team a call to find out more.