DensShield® Tile Backer

Wet Area Solutions (Aust) Pty LtdWet Area Solutions are proud to introduce DensShield® Tile Backer board to Australia. DensShield® Tile Backer has a long history of successful performance, with hundreds of millions of square metres installed in over 30 countries world-wide.

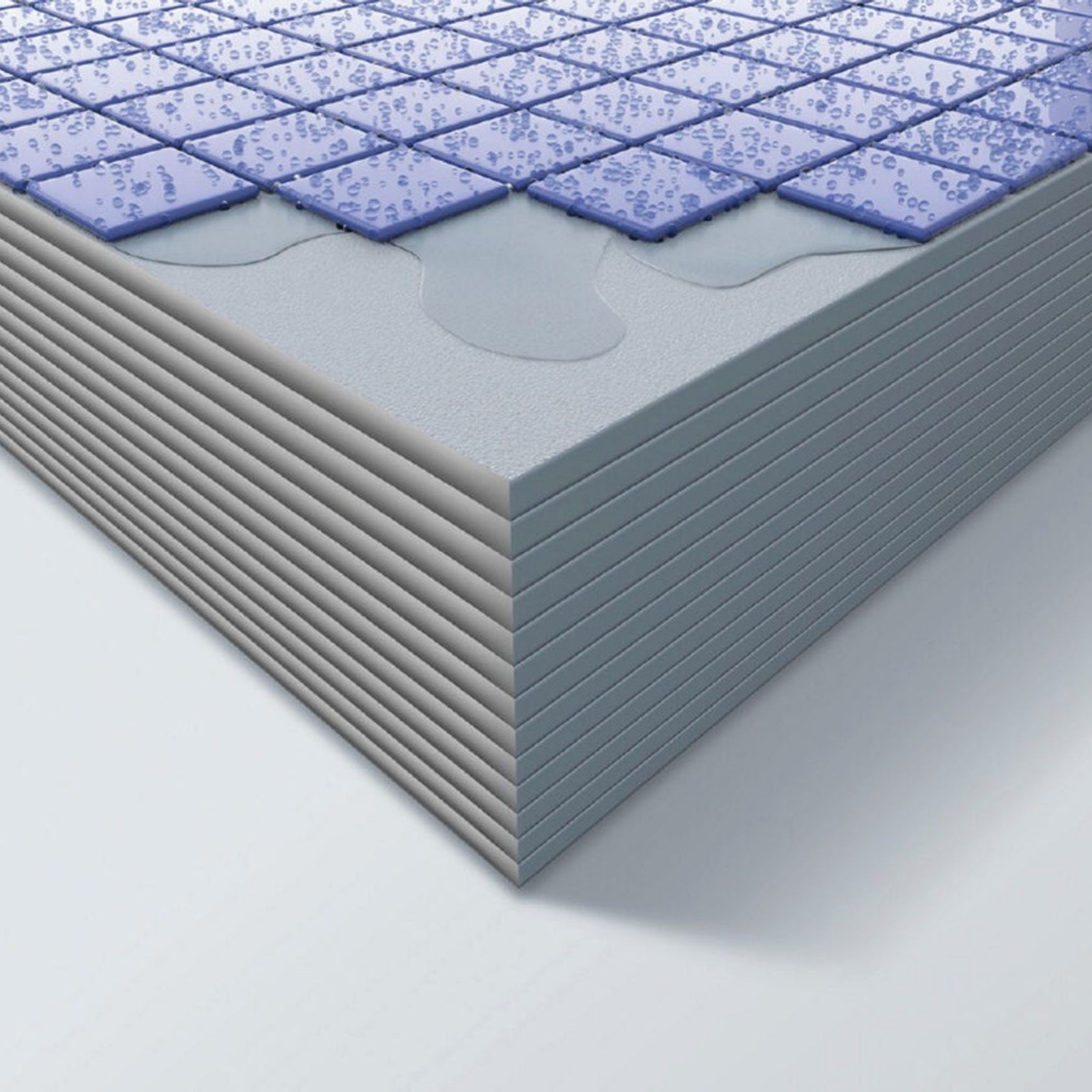

Engineered to prevent damage to the sub-floor or wall cavity if moisture seeps through grouted tile, DensShield® Tile Backer is the first backer board with a built-in moisture barrier. DensShield® Tile Backer eliminates the process of applying an additional waterproofing membrane.

It is the ideal ceramic tile underlayment for new construction, bathroom remodelling, and all high humidity or wet areas. Easier to handle than cement board, DensShield® Tile Backer cuts and installs like drywall without special tools or fasteners.

- CategoryPlaster & Plastering Supplies

- BrandGeorgia-Pacific Gypsum

- Bathrooms (shower and tub walls, floors, and ceilings)

- Kitchens (backsplash, walls, countertops, and floors)

- Residential and light commercial floors

- Non-tiled walls and ceilings in indoor swimming pool enclosures

- Residential steam rooms

Standards and Code Compliance

DensShield® Tile Backer in 6.4 mm, 12.7 mm and 15.9 mm thicknesses conforms to current IRC and IBC codes for use as a tile backer in tub and shower areas and is manufactured to meet ASTM C1178 as a fiberglass mat gypsum substrate for use as tile backer. DensShield Tile Backer also has the following evaluation reports:

- ICC-ES product approved

- New York City MEA 65-88-M

Floor Test— Robinson Floor Test/ASTM C627

An independent testing agency conducted the Robinson Floor Test (ASTM C627) on DensShield Tile Backer by constructing assemblies and subjecting them to tests of increasing weight and durability. Ultimately, DensShield Tile Backer panels were able to withstand pressure equivalent to three stacked refrigerators without damage, resulting in 6.4 mm and 12.7 mm DensShield Tile Baker panels achieving a residential and light commercial rating for floors.

Adhesion Bond Test

CTC-Geotek conducted bond-adhesion tests comparing adhesion capabilities of DensShield Tile Backer and cement backers using various setting materials. The tests concluded that bonds with DensShield Tile Backer are as good as, if not better than, bonds with cement backers.

Shower Test

In a test by an independent testing laboratory, DensShield Tile Backer was subjected to a shower of water at 43.3°C, 12 minutes per hour, 24 hours a day, 7 days a week for six months. The installation had no grout between the tiles. No deterioration occurred to either the DensShield Tile Backer board, the framing members or the wall cavity. The DensShield Tile Backer test was designed to represent 12 years of regular shower use. Although cementitious backer boards would not likely deteriorate under the same conditions, the possibility exists for deterioration of framing members and the wall cavity due to water infiltration if a moisture barrier isn’t positioned behind the cementitious backer unit.

Percolation Test

The percolation test helps determine if an additional moisture barrier should be installed. The test consists of a 51 mm diameter tube, 1220 mm long, bonded to test samples with silicone sealant. The tube is filled with water and after 48 hours, the remaining water is measured (minus evaporation).

During testing, the following occurred:

- 3 mm of water passed through DensShield Tile Backer

- 483 mm of water passed through one cementitious tile substrate sample

- 1092 mm of water passed through another sample of cement board.

The test demonstrates DensShield Tile Backer stops water at the surface, while cement boards allow water to pass through their porous construction. The Tile Council of North America requires the use of a membrane in wet areas for cement backer boards but does not require a membrane for DensShield Tile Backer since DensShield Tile Backer panels have a built-in moisture barrier that stops moisture at the surface.

Water Vapor Transmission

ASTM E96 test method intends to measure the rate of water movement through a material’s surface over a period of time. This is accomplished under controlled conditions of temperature and humidity. It is used to assess the passage of water vapor through paper, plastic films, other sheet materials, fiberboards, wood products, gypsum and plaster products.

Mould Resistance Test

Tests conducted by SGS U.S. Testing Company Inc., an independent testing service based in Tulsa, OK, have indicated that DensShield Tile Backer effectively resists mould growth. When tested, as manufactured, in accordance with ASTM D3273, DensShield Tile Backer has scored a 10, the highest level of performance for mould resistance under the ASTM D3273 test method.

DensShield Tile Backer is listed as a GREENGUARD microbial resistant product by a leading third-party organization, UL Environment. This listing means DensShield Tile Backer, which features fiberglass mats, resists microbial contamination including mould growth. The microbial-resistant test is based on ASTM Standard D6329, a testing standard set by ASTM International, which develops testing guidelines and procedures

1. Grey, heat-cured acrylic surface coating

The grey coating on the tile application side of DensShield Tile Backer is a multi-coat, heat-cured, copolymer acrylic that provides a moisture barrier that stops water and retards moisture at the surface. This coating also serves as an ideal bondable surface for a variety of tile setting mortars and mastics. Because of this coating, no additional moisture barrier is required or recommended behind DensShield Tile Backer to protect the wall cavity.

2. Fiberglass mats on both sides of the panel

To add strength and rigidity, the core has fiberglass mats on both sides of the panel that are impregnated into the panel in the manufacturing process. This construction, combined with the tile-side acrylic coating, eliminates the possibility of delamination associated with paper-faced gypsum board. The added strength also means that DensShield Tile Backer can be fastened either vertically or

horizontally to the supporting framing members, which can result in fewer joints.

3. Moisture-resistant treated core

The high-performance, moisture-resistant core of DensShield Tile Backer is specially treated to add further moisture protection. The specially engineered core doesn’t allow DensShield Tile Backer panels to wick moisture like competing cement board products.

Lifetime limited warranty when used in residential tile installations

20-Year limited warranty for commercial installations

For more information, please see the warranty.

More from Wet Area Solutions (Aust) Pty Ltd

About the

Seller

Wet Area Solutions (Aust) Pty Ltd are an Australian custom design and manufacturing company who ship their products Australia wide from their base in Geelong, Victoria. With over 30 years experience in the bathroom industry, our innovative products are designed to make your next bathroom incredible.

We specialise in custom making to client specifications and manufacture all of our tile-over shower trays and solid-surface shower bases in Geelong, using state of the art technology and machinery.

- ArchiPro Member since2022

- LocationView address

- More information