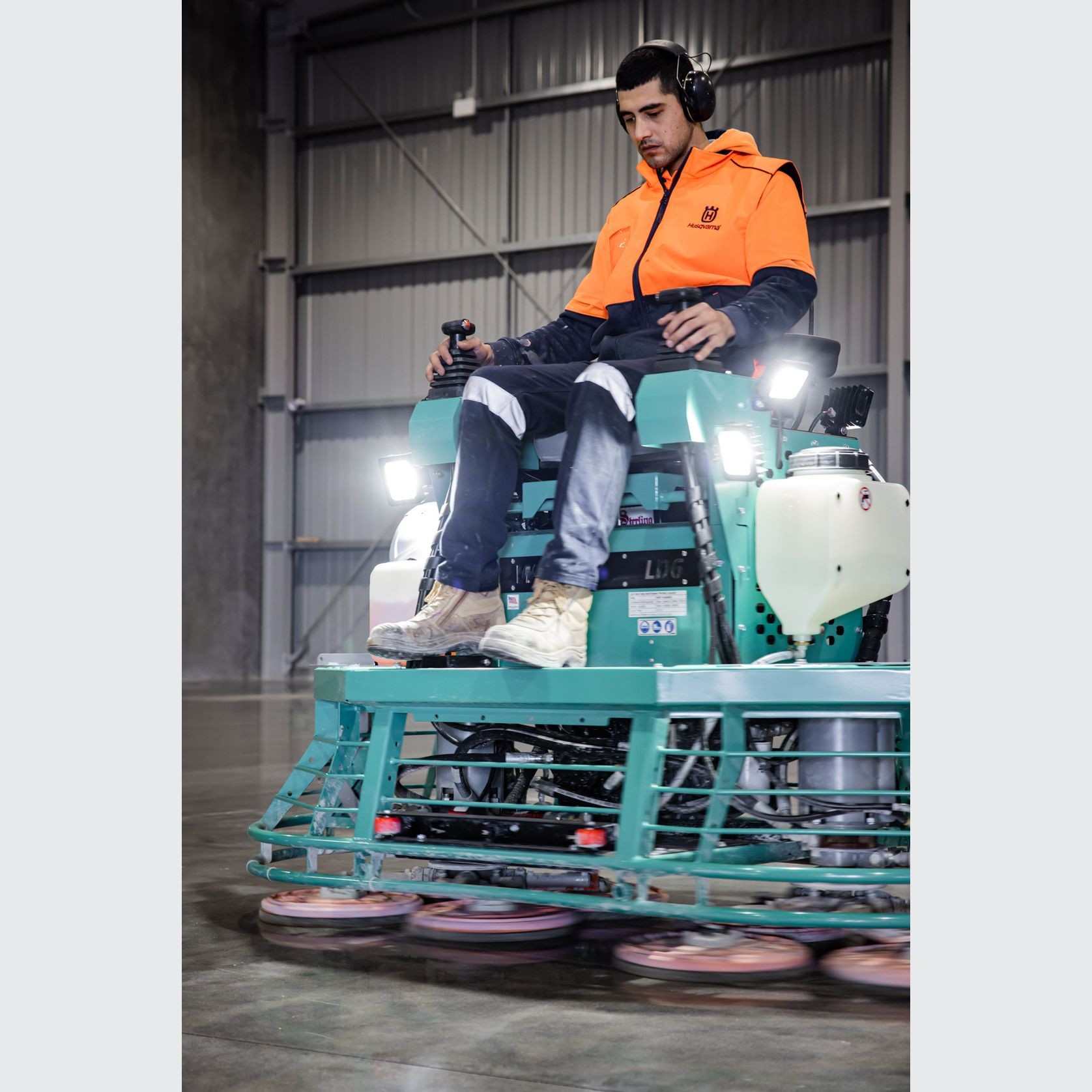

Husqvarna HiPERTROWEL™

Youngman Richardson- CategoryConcrete Flooring

- RangeHusqvarna HiPERTROWEL

- BrandHusqvarna

About the

Seller

Youngman Richardson is a fully New Zealand owned private company that has been serving the construction, hire and agricultural industries for over 40 years.

We are a leading importer and distributor of contracting, industrial and commercial equipment, with a customer base throughout New Zealand.

Our company has a reputation for quality, service and ethics.

We pride ourselves on our commitment to customers, product knowledge and expertise with a spare parts service that’s “the best in the business”.

We are the New Zealand distributors for a wide range of products, recognised worldwide for their quality and reliability. All the products we supply meet our high standard of performance and are chosen for their suitability to perform in New Zealand conditions.

We also manufacture and assemble onsite using genuine New Zealand parts and are proud to be 100% NZ owned and operated.

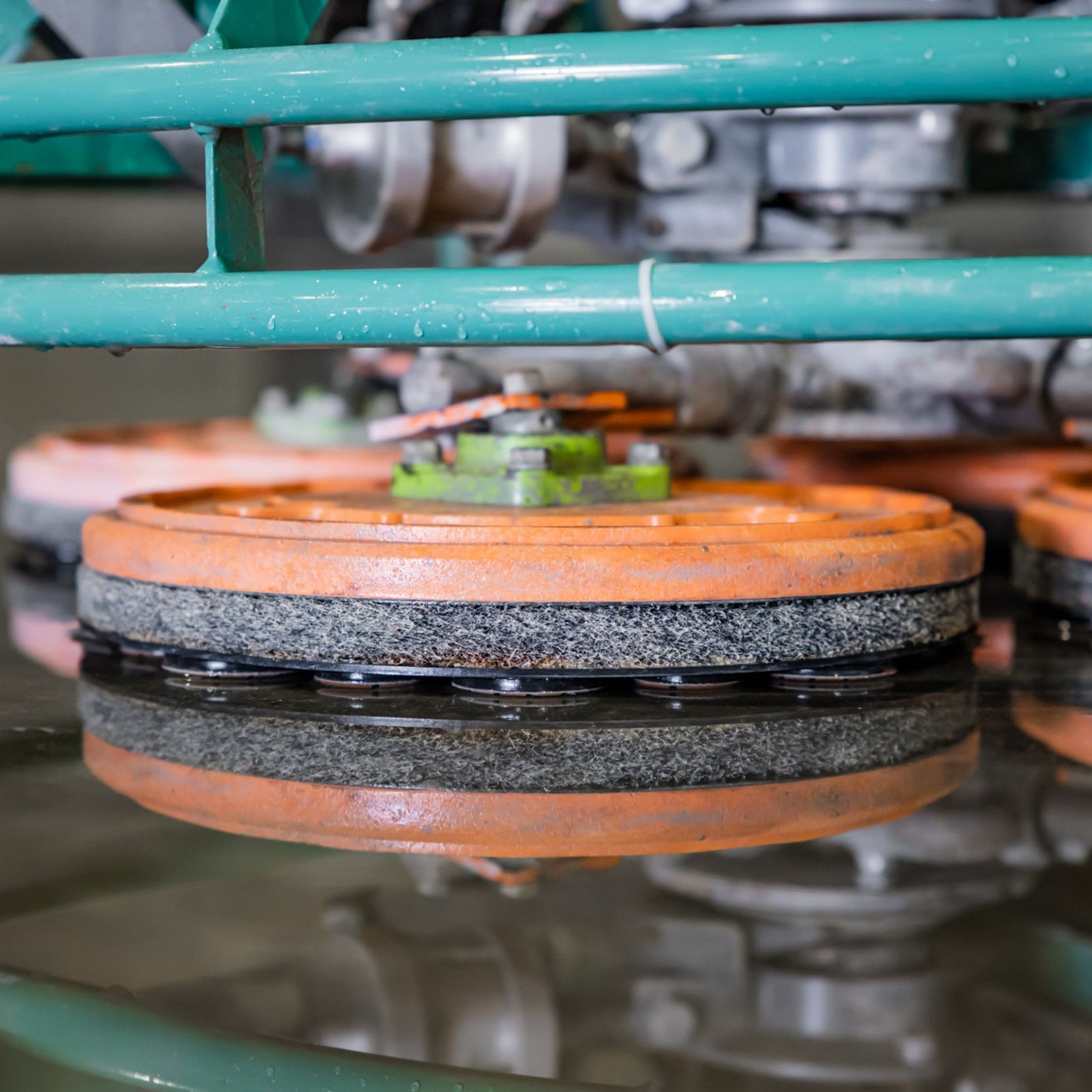

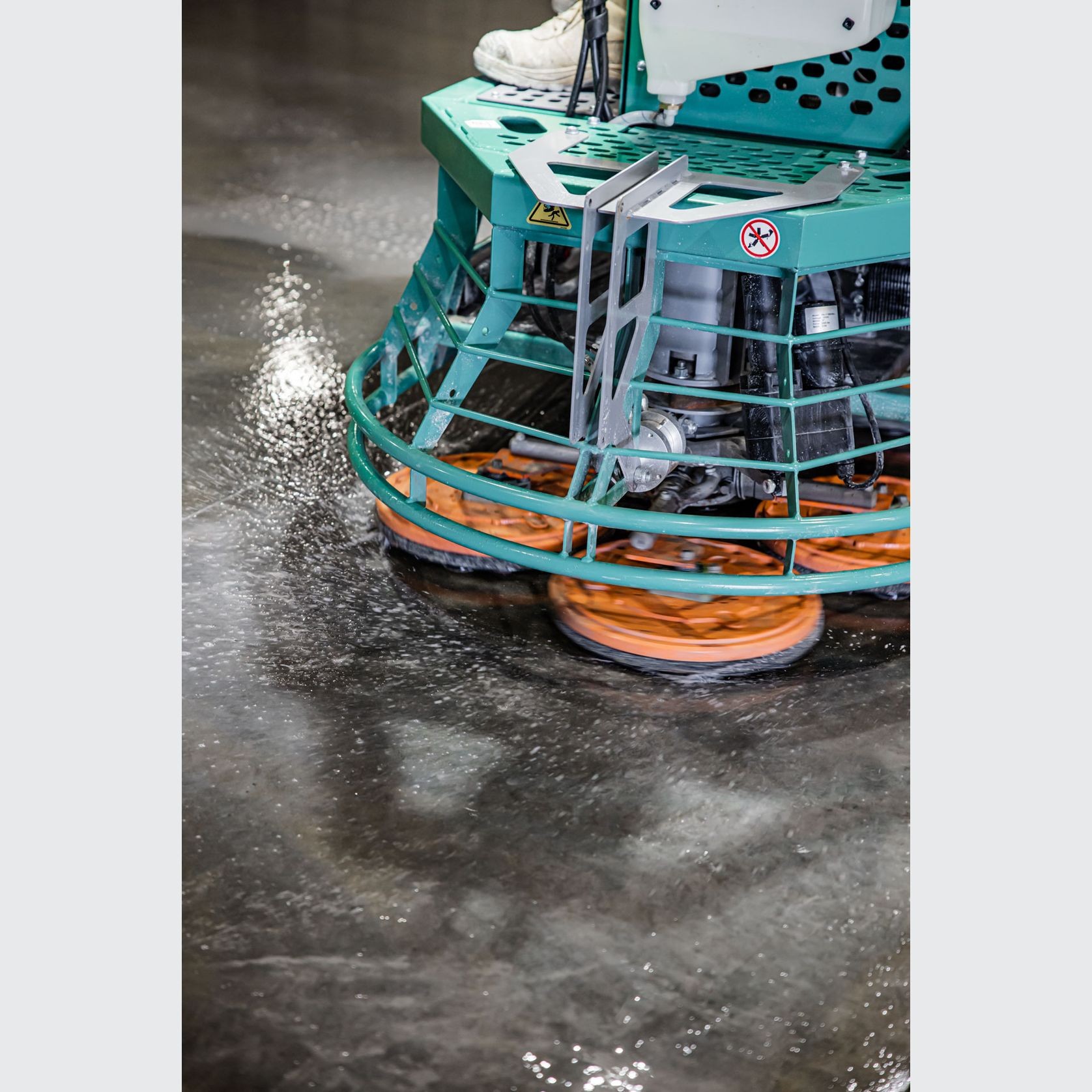

We are specialists in concrete floor preparation and offer the Husqvarna range of concrete floor grinding and polishing machines and scarifiers for all kinds of floor preaparation jobs. Applications range from prepration for and removal of coatings, surface flattening, honing and polishing of concrete and natural stone surfaces.

- ArchiPro Member since2023

- LocationView all locations (+3)

- More information